Ў™Ў≠ЎѓўКЎѓ ЎІўДўДЎ≤ўИЎђўЗ ўДўИўВўИЎѓ Ў≤ўКЎ™ўК Ў®ЎІЎ≥Ў™ЎЃЎѓЎІўЕ ЎђўЗЎІЎ≤ ЎІўЖўГўДЎ±

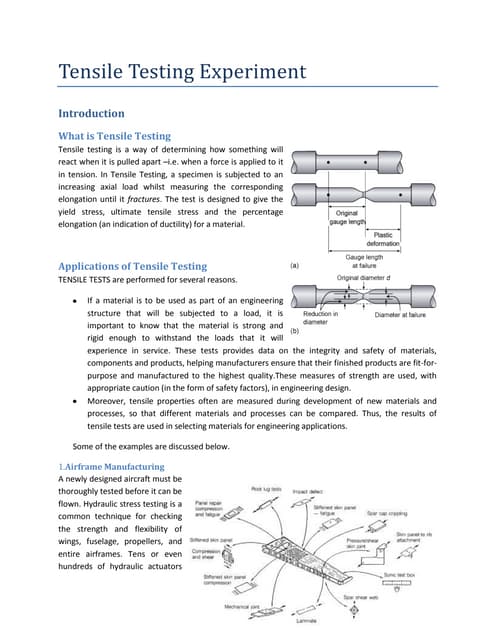

- 1. Baghdad University College of Engineering Department of Mechanical Engineering Name of Experiment "вАЂпЇЧпЇ£ЎѓпѓЊЎѓвАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂпїЯўИпїЧўИЎѓвАђвАЂЎ≤пѓЊпЇЧпї≤вАђвАЂпЇСпЇОпЇ≥пЇЧпЇІЎѓЎІўЕвАђвАЂпЇЯпЃ≠пЇОЎ≤вАђвАЂЎІпїІпїЫпї†Ў±вАђ" Preparation: Saif al-Din Ali Madi The second phase Group "A "

- 2. вАЂпЇЧпЇ£ЎѓпѓЊЎѓвАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂпїЯўИпїЧўИЎѓвАђвАЂЎ≤пѓЊпЇЧпї≤вАђвАЂпЇСпЇОпЇ≥пЇЧпЇІЎѓЎІўЕвАђвАЂпЇЯпЃ≠пЇОЎ≤вАђвАЂЎІпїІпїЫпї†Ў±вАђ вАЂпї£ўЖвАђ вАЂЎІпїЯпїРЎ±ЎґвАђвАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ:вАЂЎ•пѓЊпЇЯпЇОЎѓвАђвАЂпїЛпїЉпїЧпЇФвАђвАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпї£пїКвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпЇЧўИпЇњпѓЊпЇҐвАђвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЎІпїЯпї£ўИЎІпЇЛпїКвАђ:вАЂпїЯпї†пЇІўИЎІЎµвАђ вАЂпї£пїШпѓЊпЇОЎ≥вАђ вАЂЏЊпї≤вАђвАЂЎІпїЯпЇ≥Ў±пѓЊпЇОпїІпѓЊпЇФвАђвАЂпЇСпЇОЎ±пЇЧпїФпЇОЎєвАђ вАЂЎІпїЯпЇ≥Ў±пѓЊпЇОўЖвАђ вАЂпї£пїМЎѓўДвАђ вАЂўИпѓЊЎ≤пѓЊЎѓвАђ вАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпїЯпЃ≠Ў∞ЎІвАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђвАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпЇ£Ў±ЎІЎ±ўЗвАђЎМвАЂЎ£ўИвАђвАЂЏЊпї≤вАђвАЂпЇІпЇОпЇїпѓЊпЇФвАђвАЂЎІпїЯпї£пЇЧпЇЯпЇОпїІЎ≥вАђ вАЂЎІпїЯпї£пЇОпЇЛпїКвАђвАЂпїЈпЇЧпї≤вАђвАЂпЇЧпЇЯпїМпї†пЃЂвАђвАЂпѓЊпЇСЎѓўКвАђ вАЂпЇ£вАђ вАЂпЇІпїЉўДвАђ вАЂЎІпЇ£пЇЧпїЫпЇОўГвАђ вАЂпї£пїШпЇОўИпї£пЃЂвАђвАЂпїУвАђ вАЂўИпЇІпїЉўДвАђ вАЂЎ±пїЫпЇЧпЃЂвАђвАЂўИЎІпїЯпїІпЇОпЇЧпЇЯпЇФвАђ вАЂпї£пїМпѓЊпїІпЃЂвАђ вАЂЎ≤пї£пїІпѓЊпЃЂвАђ вАЂпЇЧЎ±ўЗвАђвАЂпЇСпѓЊўЖвАђ вАЂЎІпїЯпЇЧпї£пЇОпЇ≥ўГвАђ вАЂпїЧўИўЗвАђ вАЂпї£ўЖвАђ вАЂЎІпїЯпЇЯЎ≤пѓЊпЇЛпЇОЎ™вАђ вАЂЏЊпї≤вАђ вАЂЎ£пїІўИЎІЎєвАђ вАЂпїЛЎѓўЗвАђ вАЂЎ•пїЯпї∞вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпЇЧпїШпЇ≥пѓЊўЕвАђ вАЂўИпѓЊпї£пїЫўЖвАђ: ў°.вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЏЊпЇОўИвАђ вАЂЎІпїЯпї£ЎЈпї†ўВвАђвАЂЎІпїЯЎѓпѓЊпїІпЇОпї£пѓЊпїЫпѓЊпЇФвАђ)dynamics viscosity: (вАЂЏЊпї≤вАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЎІпїЯпїІпЇОпЇЧпЇЯпЇФвАђвАЂпї£ўЖвАђ вАЂпЇСпЇОпїЯЎ±пї£Ў≤вАђ вАЂпїЯпЃ≠пЇОвАђ вАЂўИпѓЊЎ±пї£Ў≤вАђ вАЂЎІпїЯпїШЎµвАђ вАЂпїЧўИўЙвАђ вАЂпЇСўИпЇЯўИЎѓвАђ вАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпЇ£Ў±пїЫпЃЂвАђ)ќЉ(вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂўИпЇЧпїШпЇОЎ≥вАђ. вАЂпѓЊпЇ≥пї£пї∞вАђ вАЂўИЎІпїЯЎ∞ўКвАђpoise ўҐ.вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЎІпїЯпїЫпѓЊпїІпї£пЇОпЇЧпѓЊпїЫпѓЊвАђвАЂпЇФвАђ)kinematics viscosity: (вАЂпЇСпЇОпїЯЎ±пї£Ў≤вАђ вАЂпїЯпЃ≠пЇОвАђ вАЂўИпѓЊЎ±пї£Ў≤вАђvвАЂўИпЇЧпїШпЇОЎ≥вАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђsвБДвАЂпѓЊпЇ≥пї£пї∞вАђ вАЂўИЎІпїЯЎ∞ўКвАђstokeвАЂЎ•пї£пЇОвАђвАЂпї£пїКвАђ вАЂпїЛпїЉпїЧпЇЧпЃ≠пЇОвАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЎІпїЯЎѓпѓЊпїІпЇОпї£пѓЊпїЫпѓЊпЇФвАђвАЂЏЊпї≤вАђ: вАЂпЇ£пѓЊЎЂвАђpвАЂЏЊпї≤вАђвАЂпїЫпЇЫпЇОпїУпЇФвАђвАЂЎІпїЯпї£пЇОпЇЛпїКвАђ ў£.вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЎІпїЯпЇЧпЇЯпЇОЎ±пѓЊпЇФвАђвАЂўИЏЊпї≤вАђвАЂЎІпїЈпїЫпЇЫЎ±вАђвАЂўИўИпЇ£ЎѓвАђ вАЂўИЎІпЇ≥пЇЧпЇІЎѓЎІпї£пЇОвАђ вАЂпЇЈпѓЊўИпїЛпЇОвАђвАЂЎІпЇЧпЃ≠пЇОвАђSAEвАЂпї£ўЖвАђ вАЂпїЛпї†пѓЊпЃ≠пЇОвАђ вАЂпЇЧпїМЎ±пїУпїІпЇОвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂпЇІпїЉўДвАђвАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђвАЂЎІпїЈўИпїЯпї∞вАђ вАЂўИЏЊпї≤вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂЎІпїЛпЇЧпї£ЎѓЎ™вАђ вАЂЎ±пЇЛпѓЊпЇ≥пѓЊпЃЂвАђ вАЂЎЈЎ±ўВвАђ вАЂпЇЫпїЉЎЂвАђ вАЂЏЊпїІпЇОўГвАђ: ў°.вАЂЎІпїЯпїМЎ≤ўЕвАђ вАЂпї£пїМЎ±пїУпЇФвАђвАЂЎ£пїїЎ≤ўЕвАђвАЂпїЯпЇЧЎѓўИпѓЊЎ±вАђвАЂЎІпЇ≥ЎЈўИЎІпїІпЇФвАђвАЂпї£пїРпї£ўИЎ±Ў©вАђвАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпЇЧЎ≤ЎѓЎІЎѓвАђ вАЂпїЫпї†пї£пЇОвАђ вАЂпЇ£пѓЊЎЂвАђ вАЂпї£пЇОпЇЛпїКвАђ вАЂпїУпї≤вАђ "вАЂЎІпїЯЎ≤пѓЊЎ™вАђ"вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓўЕвАђвАЂЎ£пїїЎ≤ўЕвАђвАЂпїЯпї†пЇЧЎѓўИпѓЊЎ±вАђ ўҐ.вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпї£пїМЎ±пїУпЃЂвАђвАЂЎ£пїїЎ≤ўЕвАђвАЂпїЯпї£пЇОпЇЛпїКвАђ вАЂпЇ£ЎѓпѓЊЎѓпѓЊпЇФвАђ вАЂпїЫЎ±Ў©вАђ вАЂпїїпЇ£пЇЧЎ±ЎІўВвАђвАЂўИпїЯпї£пЇ≥пЇОвАђвАЂпїУпЇФвАђвАЂпї£пїМпї†ўИпї£пЇФвАђвАЂпї£пїШЎѓЎІЎ±ЏЊпЇОвАђLвАЂпїІпїШўИўЕвАђ вАЂпЇ£пѓЊЎЂвАђ вАЂпЇСпЇИпЇ≥пїШпЇОЎЈвАђвАЂпїЫЎ±Ў©вАђвАЂпЇ£ЎѓпѓЊЎѓўЗвАђвАЂпї£ўЖвАђвАЂЎІпїЛпї†пї≤вАђвАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпЇ≥ЎЈпЇҐвАђвАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпЇ£пЇ≥пЇОЎ®вАђ вАЂпѓЊпЇЧўЕвАђ вАЂпї£пїМпѓЊпїІпЃЂвАђ вАЂўИпїЯпї£пЇ≥пЇОпїУпЇФвАђ вАЂЎІпїєпїІпЇОЎ°вАђ вАЂпїЧпїМЎ±вАђ вАЂЎ•пїЯпї∞вАђ вАЂпїЯўИпЇїўИпїЯпЃ≠пЇОвАђЎМвАЂЎІпїЯпїЫЎ±Ў©вАђ вАЂпїЯўИпЇїўИўДвАђ вАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпѓЊЎ≤ЎѓЎІЎѓвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂЎІЎ≤ЎѓЎІЎѓЎ™вАђ вАЂпїУпїЫпї†пї£пЇОвАђ вАЂЎІпїєпїІпЇОЎ°вАђ вАЂпїЧпїМЎ±вАђ вАЂЎ•пїЯпї∞вАђ ў£.вАЂЎІпїІпїЫпї†Ў±вАђ вАЂЎЈЎ±пїЧпЃЂвАђЎМвАЂпї£пїМпї†ўИпї£вАђ вАЂпїЫпї£пѓЊпЇФвАђ вАЂпїЯпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпї£пїМЎ±пїУпЃЂвАђ вАЂпѓЊпЇЧўЕвАђ вАЂпЇІпїЉпїЯпЃ≠пЇОвАђ вАЂпї£ўЖвАђвАЂЎІпїЯЎ∞ўКвАђ вАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпї£ўЖвАђ вАЂпЇФвАђ вАЂпЇїпїРпѓЊЎ±Ў©вАђ вАЂЎ£пїІпЇСўИпЇСпЃЂвАђ вАЂпЇІпїЉўДвАђ вАЂпѓЊпїІпЇ≥пЇОЎ®вАђЎМвАЂЎІпїЯпЇСпЇЧЎ±ўИпїЯпѓЊпЇФвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂЎ£пїЯЎЈЎ±пѓЊпїШпЃЂвАђ вАЂЏЊЎ∞ўЗвАђ вАЂўИпїІпЇ≥пЇЧпЇІЎѓўЕвАђ "вАЂЎІпїЯпЇїпїІпЇОпїЛпѓЊпЇФвАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ"

- 3. вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂЏЊўИвАђ вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂЏЊЎ∞ўЗвАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпї£пЃ≠пї£пЇФвАђ вАЂЎІпїЯпї£пЇїЎЈпї†пЇ£пЇОЎ™вАђ вАЂпї£ўЖвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пїМпЇОпї£ўДвАђ)indexviscosity: ( вАЂпї£ЎѓўЙвАђ вАЂпїЛўЖвАђ вАЂпѓЊпїМпЇСЎ±вАђ вАЂпї£пЇїЎЈпї†пЇҐвАђ вАЂЏЊўИЎ©вАђвАЂпїЧпЇОпЇСпї†пѓЊпЃЂвАђвАЂЎІпїЯпї£пЇОпЇЛпїКвАђвАЂпїЯпї†пї£пЇ£пЇОпїУЎЄпЇФвАђвАЂпїЯЎ≤ўИпЇЯпЇЧпЃЂвАђ вАЂпїЛпї†пї∞вАђвАЂЎ£ўИвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпЇЧпїРпѓЊЎ±вАђ вАЂпї£пїКвАђ вАЂпї£пїШпѓЊпЇОЎ≥вАђ вАЂЏЊўИЎ©вАђвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂЎІЎ±пЇЧпїФпЇОЎєвАђ вАЂпї£пїКвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїЯпЇЧпїРпѓЊЎ±вАђЎМвАЂЎ•пїЯпї∞вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂпЇ£пЇ≥Ў®вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂўИпЇЧпїШпЇ≥ўЕвАђ вАЂпїІўИпїЛпѓЊўЖвАђ: ў°.вАЂпї£пїКвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїУпї≤вАђ вАЂпїЫпЇСпѓЊЎ±вАђ вАЂпЇЧпїРпѓЊпѓЊЎ±вАђ вАЂпЇЧпїМпЇОпїІпї≤вАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂўИЏЊпї≤вАђ вАЂпї£пїІпЇІпїФЎґвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂЎ∞ўИвАђ вАЂЎ≤пѓЊЎ™вАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђЎМвАЂпЇЧпїЫўИўЖвАђ вАЂпЇ£пѓЊЎЂвАђвАЂЎІпїЯпїМпїЉпїЧпЇФвАђвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂўИЎѓЎ±пЇЯпЃЂвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпЇСпѓЊўЖвАђвАЂпїЛпїЉпїЧпЇФвАђвАЂпїЛпїЫпЇ≥пѓЊпЇФвАђ вАЂпЇСпЇОўЖвАђ вАЂўИЎ∞пїЯўГвАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂпїУпї≤вАђ вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓпї£пЇФвАђ вАЂЎІпїЯпЇЧпЇЯпЇОЎ±пѓЊпЇФвАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂпї£пЇЫўДвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂпЇСпЇОЎ±пЇЧпїФпЇОЎєвАђ вАЂпЇЧпїШўДвАђ вАЂпЇЧпЇ£пЇЧпЇОЎђвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯпЇ≥пѓЊпЇОЎ±ЎІЎ™вАђ вАЂпї£пїЫпЇОпЇЛўЖвАђвАЂЎ•пїЯпї∞вАђвАЂпї£ЎѓЎ©вАђ вАЂпЇСпѓЊўЖвАђ вАЂпЇЧпЇСЎѓпѓЊўДвАђвАЂўИЎ£пЇІЎ±ўЙвАђ. ўҐ.вАЂпїУпѓЊпЃ≠пЇОвАђ вАЂпѓЊпїЫўИўЖвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂўИЏЊпї≤вАђ вАЂпї£Ў±пЇЧпїФпїКвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂЎ∞ўИвАђ вАЂЎ≤пѓЊЎ™вАђвАЂпЇЧпЇДпЇЫпѓЊЎ±вАђвАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпЇЧпїРпѓЊпѓЊЎ±вАђ вАЂЎІпїЯпЇ£Ў±ЎІвАђвАЂЎ±Ў©вАђвАЂпїЛпї†пї∞вАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂпЇЈпЇСпЃЂвАђвАЂпї£пїМЎѓўИпї£пЇФвАђвАЂпїУпѓЊпїЉпЇ£ЎЄвАђвАЂЎ•ўЖвАђвАЂЎІпїЯпї†Ў≤ўИвАђвАЂпЇЧпЇСпїШпї∞вАђ вАЂпЇЯпЇФвАђвАЂпЇЫпЇОпЇСпЇЧпЇФвАђвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпї£пїКвАђ вАЂпЇСпЇ≥пЇСЎ®вАђ вАЂўИЎ∞пїЯўГвАђ вАЂЎІпїЯпї£Ў±пЇЧпїФпїМпЇФвАђвАЂЎ£пЇњпЇОпїУпЃЂвАђвАЂпїЛпї†пї∞вАђ вАЂпЇЧпїМпї£ўДвАђ вАЂпїЫпѓЊпї£пѓЊпЇОпЇЛпѓЊпЃЂвАђ вАЂпї£ўИЎІЎѓвАђвАЂЎІпїЯпї£пЇ£пЇОпїУЎЄпЇФвАђвАЂўИпї£ўЖвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпїЛпї†пї∞вАђ вАЂпїУўИЎІпЇЛЎѓЏЊпЇОвАђвАЂЎ£пїІпЃ≠пЇОвАђвАЂпЇЧпЇ£пЇЧпЇОЎђвАђ вАЂпїївАђвАЂЎ•пїЯпї∞вАђвАЂпї£пїЫпЇОпЇЛўЖвАђ вАЂпїУпї≤вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂЏЊЎ∞ўЗвАђ вАЂўИпЇЧпЇ≥пЇЧпЇІЎѓўЕвАђ вАЂўИЎ£пЇІЎ±ўЙвАђ вАЂпїУпЇЧЎ±ўЗвАђ вАЂпЇСпѓЊўЖвАђ вАЂпЇЧпЇСЎѓпѓЊўДвАђ вАЂЎІпїЯпЇїўИЎІЎ±пѓЊпЇ¶вАђ вАЂўИпї£пЇ£Ў±пїЫпЇОЎ™вАђ вАЂЎІпїЯпїФпЇњпЇОпЇЛпѓЊпЇФвАђ вАЂЎІпїЯпї£Ў±пїЫпЇСпЇОЎ™вАђ. вАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇЯпЃ≠пЇОЎ≤вАђ: вАЂпї£пЇ≥пїМЎ±пѓЊўЖвАђ вАЂпї£ўЖвАђ вАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇЯпЇОЏЊЎ≤вАђ вАЂпѓЊпЇЧпїЫўИўЖвАђвАЂпЇІвАђвАЂўИЎѓЎІпЇІпї†пї≤вАђ вАЂпЇОЎ±пЇЯпї≤вАђЎМвАЂпЇСпЇ£пЇЯўЕвАђ вАЂпЇСпЇОпїЯпї£пЇОЎ°вАђ вАЂЎІпїЯпЇІпЇОЎ±пЇЯпї≤вАђ вАЂЎІпїЯпї£пЇ≥пїМЎ±вАђ вАЂпї£пї†пЇКвАђ вАЂпѓЊпЇЧўЕвАђ вАЂпї£пїШЎѓЎІЎ±ўЗвАђ1000 ЎМвАЂЎ•пї£пЇОвАђвАЂЎІпїЯпї£Ў±ЎІЎѓвАђ вАЂпЇСпЇОпїЯЎ≤пѓЊЎ™вАђ вАЂпїУпѓЊпї£пї†пЇКвАђ вАЂЎІпїЯЎѓЎІпЇІпї†пї≤вАђ вАЂЎІпїЯпї£пЇ≥пїМЎ±вАђвАЂЎ•пѓЊпЇЯпЇОЎѓвАђвАЂпїУпї≤вАђ вАЂЎІпїЯпЇЧпїРпѓЊпѓЊЎ±вАђвАЂпїЯЎ≤ўИпЇЯпЇЧпЃЂвАђвАЂпї£пїКвАђ вАЂпЇСпЇ£пЇЯўЕвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ вАЂЎІЎ±пЇЧпїФпЇОЎєвАђ270 вАЂпїЛпї†пї∞вАђ вАЂЎІпїЯпЇЯпЃ≠пЇОЎ≤вАђ вАЂпѓЊпЇ£пЇЧўИўКвАђвАЂпѓЊвАђ вАЂпї£пЇ£Ў±ЎІЎ±вАђвАЂўЖвАђвАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпї£пЇ≥пїМЎ±вАђ вАЂпїУпї≤вАђ вАЂЎІпЇ£ЎѓЏЊпї£пЇОвАђвАЂпїУпї≤вАђ вАЂўИЎІпїЈпЇІЎ±вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпїЯЎ≤пѓЊЎ™вАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£пЇ≥пїМЎ±вАђЎМвАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ вАЂпЇЧпЇ£ЎѓпѓЊЎѓвАђ вАЂпѓЊпЇЧўЕвАђ вАЂЎІпїЯпї£пЇ£Ў±ЎІЎ±пѓЊўЖвАђ вАЂпЇІпїЉўДвАђ вАЂўИпї£ўЖвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ.. вАЂпЇСпЇИпЇ£пїЫпЇОўЕвАђ вАЂпї£пїРпї†пїШпЇФвАђ вАЂўИпЇЧпїЫўИўЖвАђ вАЂпї£пїІпЃ≠пЇОвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯпЇЧЎѓпїУўВвАђ вАЂпЇїпїРпѓЊЎ±Ў©вАђ вАЂпїУпЇЧпЇ£пЃЂвАђ вАЂпїЛпї†пї∞вАђ вАЂЎ£пЇ≥пїФпї†пЇФвАђ вАЂпїУпї≤вАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£пЇ≥пїМЎ±вАђ вАЂпѓЊпЇ£пЇЧўИўКвАђ вАЂпїЧЎЈпїМпЇФвАђ вАЂпЇСўИЎІпЇ≥ЎЈпЇФвАђ вАЂЎІпїЯпЇІпЇЈЎ®вАђ вАЂпї£ўЖвАђ..вАЂпїЫвАђвАЂпЇ£Ў±ЎІЎ±ўКвАђ вАЂўИпї£пЇ≥пЇІўЖвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђ вАЂпї£пїМпѓЊўЖвАђ вАЂпї£пїШЎѓЎІЎ±вАђ вАЂпїЯпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎѓўИЎ±ўВвАђ вАЂпїЛпї†пї∞вАђ вАЂЎІпїЯпЇЯпЃ≠пЇОЎ≤вАђ вАЂпѓЊпЇ£пЇЧўИўКвАђ вАЂЎ∞пїЯўГвАђ вАЂпїЯпЇЧвАђвАЂЎІпїЯпїЉЎ≤вАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпїЯпїШпѓЊпЇ≥пЇОвАђ вАЂЎ±пїЧпї£пѓЊпЇФвАђ вАЂўИпЇ≥пЇОпїЛпЇФвАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпЇ≥пЇІпѓЊўЖвАђвАЂўЕвАђвАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђ вАЂЎІпїЯпї£пїМпї†ўИпї£пЇФвАђ вАЂЎІпїЯпїЫпї£пѓЊпЇФвАђ вАЂпїЯпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ:вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂпїІпїФЎ≥вАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпї£пїКвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїУпѓЊпЃ≠пЇОвАђ вАЂпѓЊпїЫўИўЖвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±пѓЊпЇФвАђ вАЂЎІпїЯЎѓЎ±пЇЯпЇФвАђ вАЂўИЏЊпї≤вАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎІпїЯпїШЎ±ЎІЎ°ЎІЎ™вАђ вАЂпЇЯЎѓўИўДвАђ:вАЂпїЧпѓЊпЇОЎ≥вАђ вАЂўИпїЫЎ∞пїЯўГвАђ вАЂЎІпїЯпї£пЇ£Ў±ЎІЎ±пѓЊўЖвАђ вАЂпЇІпїЉўДвАђ вАЂпї£ўЖвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±ўКвАђ вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂпїЧпѓЊпЇОЎ≥вАђ вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂпЇІпїЉўДвАђ вАЂпѓЊпЇЧўЕвАђ вАЂЎІпїЯЎ≤пї£вАђвАЂпїЯпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎІпїЯпїЉЎ≤ўЕвАђ вАЂўЖвАђ25 вАЂЎІпїЯпЇЧпЇОпїЯпѓЊпЇФвАђ вАЂпЇСпЇОпїЯпїМпїЉпїЧпЇФвАђ вАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпЇ£пЇ≥пЇОЎ®вАђ вАЂпѓЊпЇЧўЕвАђ вАЂпЇ£пѓЊЎЂвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђ

- 4. вАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ= вАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ= вАЂЎІпїЯпЇ£пЇ≥пЇОпЇСпЇОЎ™вАђ ў£.вАЂЎІвАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯЎ≤ўИпЇЯпЇФвАђвАЂпїІвАђвАЂпїЫпї†Ў±вАђ= 7.87 = вИЧ . ў°.вАЂЎІвАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯЎ≤ўИпЇЯпЇФвАђвАЂпїІвАђвАЂпїЫпї†Ў±вАђ= 15.46 = вИЧ . ў§.вАЂЎІвАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯЎ≤ўИпЇЯпЇФвАђвАЂпїІвАђвАЂпїЫпї†Ў±вАђ= 5.32 = вИЧ . ў£.вАЂЎІвАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯЎ≤ўИпЇЯпЇФвАђвАЂпїІвАђвАЂпїЫпї†Ў±вАђ= 11.07 = вИЧ NOвАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђвДГвАЂпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђ25 вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђвАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ ў°16100.5 ўҐ2172 ў£2751.2 ў§3134.6 вАЂпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђ200cmвАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђ вАЂЎ≤пї£ўЖвАђвАЂпЇЧпЇЯпї£пѓЊпїКвАђ200cmвАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпї£ўЖвАђ вАЂпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђвАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђ=вАЂпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђвИЧ вАЂпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђ200cmвАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпї£ўЖвАђ=52 sec =вАЂпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђ8 вИЧ 25 вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпї£ўЖвАђ 52 sec

- 5. вАЂЎ£пЇ≥пЇЛпї†пЇФвАђвАЂЎІпїЯпї£пїІпЇОпїЧпЇЈпЇФвАђ:- ў°.вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓўЕвАђ вАЂЎІпїЯпЇЯпЃ≠пЇОЎ≤вАђ вАЂЎ±пЇ≥ўЕвАђ ўҐ.вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпЇСпї£пїМпЇОпї£ўДвАђ вАЂЎІпїЯпї£пїШпЇїўИЎѓвАђ вАЂпї£пЇОвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пїМпЇОпї£ўДвАђ)indexviscosity: ( вАЂЎІпїЯвАђ вАЂпїЧпЇОпЇСпї†пѓЊпЃЂвАђ вАЂпї£ЎѓўЙвАђ вАЂпїЛўЖвАђ вАЂпѓЊпїМпЇСЎ±вАђ вАЂпї£пЇїЎЈпї†пЇҐвАђ вАЂЏЊўИЎ©вАђвАЂЎ£ўИвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпЇЧпїРпѓЊЎ±вАђ вАЂпї£пїКвАђ вАЂпїЯЎ≤ўИпЇЯпЇЧпЃЂвАђ вАЂпїЛпї†пї∞вАђ вАЂпїЯпї†пї£пЇ£пЇОпїУЎЄпЇФвАђ вАЂпї£пЇОпЇЛпїКвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂЎІЎ±пЇЧпїФпЇОЎєвАђ вАЂпї£пїКвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїЯпЇЧпїРпѓЊЎ±вАђ вАЂпї£пїШпѓЊпЇОЎ≥вАђ вАЂЏЊўИЎ©вАђЎМвАЂЎ•пїЯпї∞вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂпЇ£пЇ≥Ў®вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂўИпЇЧпїШпЇ≥ўЕвАђ вАЂпїІўИпїЛпѓЊўЖвАђ: ў°.вАЂпї£пїКвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїУпї≤вАђ вАЂпїЫпЇСпѓЊЎ±вАђ вАЂпЇЧпїРпѓЊпѓЊЎ±вАђ вАЂпЇЧпїМпЇОпїІпї≤вАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂўИЏЊпї≤вАђ вАЂпї£пїІпЇІпїФЎґвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂЎ∞ўИвАђ вАЂЎ≤пѓЊЎ™вАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђЎМвАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпЇСпѓЊўЖвАђ вАЂЎІпїЯпїМпїЉпїЧпЇФвАђ вАЂпЇЧпїЫўИўЖвАђ вАЂпЇ£пѓЊЎЂвАђвАЂпїЛпїЫпЇ≥пѓЊпЇФвАђ вАЂпїЛпїЉпїЧпЇФвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂўИЎѓЎ±пЇЯпЃЂвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓпї£пЇФвАђ вАЂЎІпїЯпЇЧпЇЯпЇОЎ±пѓЊпЇФвАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂпї£пЇЫўДвАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЃЂвАђ вАЂпЇСпЇОЎ±пЇЧпїФпЇОЎєвАђ вАЂпЇЧпїШўДвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпЇСпЇОўЖвАђ вАЂўИЎ∞пїЯўГвАђ вАЂўИЎ£пЇІЎ±ўЙвАђ вАЂпї£ЎѓЎ©вАђ вАЂпЇСпѓЊўЖвАђ вАЂпЇЧпЇСЎѓпѓЊўДвАђ вАЂЎ•пїЯпї∞вАђ вАЂпЇЧпЇ£пЇЧпЇОЎђвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯпЇ≥пѓЊпЇОЎ±ЎІЎ™вАђ вАЂпї£пїЫпЇОпЇЛўЖвАђ. ўҐ.вАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпЇЧпїРпѓЊпѓЊЎ±вАђ вАЂпЇЧпЇДпЇЫпѓЊЎ±вАђ вАЂпїУпѓЊпЃ≠пЇОвАђ вАЂпѓЊпїЫўИўЖвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂўИЏЊпї≤вАђ вАЂпї£Ў±пЇЧпїФпїКвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпї£пїМпЇОпї£ўДвАђ вАЂЎ∞ўИвАђ вАЂЎ≤пѓЊЎ™вАђ вАЂпЇЈвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїЛпї†пї∞вАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇОЎ™вАђ вАЂпї£пїКвАђ вАЂпЇЫпЇОпЇСпЇЧпЇФвАђ вАЂпЇЧпЇСпїШпї∞вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂЎ•ўЖвАђ вАЂпїУпѓЊпїЉпЇ£ЎЄвАђ вАЂпї£пїМЎѓўИпї£пЇФвАђ вАЂпЇСпЃЂвАђ вАЂўИпї£ўЖвАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпїЛпї†пї∞вАђ вАЂЎІпїЯпї£пЇ£пЇОпїУЎЄпЇФвАђ вАЂпїЛпї†пї∞вАђ вАЂпЇЧпїМпї£ўДвАђ вАЂпїЫпѓЊпї£пѓЊпЇОпЇЛпѓЊпЃЂвАђ вАЂпї£ўИЎІЎѓвАђ вАЂЎ£пЇњпЇОпїУпЃЂвАђ вАЂпЇСпЇ≥пЇСЎ®вАђ вАЂўИЎ∞пїЯўГвАђ вАЂЎІпїЯпї£Ў±пЇЧпїФпїМпЇФвАђ вАЂпї£пїЫпЇОпЇЛўЖвАђ вАЂпїУпї≤вАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ вАЂЏЊЎ∞ўЗвАђ вАЂўИпЇЧпЇ≥пЇЧпЇІЎѓўЕвАђ вАЂўИЎ£пЇІЎ±ўЙвАђ вАЂпїУпЇЧЎ±ўЗвАђ вАЂпЇСпѓЊўЖвАђ вАЂпЇЧпЇСЎѓпѓЊўДвАђ вАЂЎ•пїЯпї∞вАђ вАЂпЇЧпЇ£пЇЧпЇОЎђвАђ вАЂпїївАђ вАЂЎ£пїІпЃ≠пЇОвАђ вАЂпїУўИЎІпЇЛЎѓЏЊпЇОвАђ вАЂЎІпїЯпЇїўИЎІЎ±пѓЊпЇ¶вАђ вАЂўИпї£пЇ£Ў±пїЫпЇОЎ™вАђ вАЂЎІпїЯпїФпЇњпЇОпЇЛпѓЊпЇФвАђ вАЂЎІпїЯпї£Ў±пїЫпЇСпЇОЎ™вАђ. вАЂпї£пЇїЎѓЎ±вАђ вАЂпїЫпЃ≠Ў±пЇСпЇОЎ°вАђ вАЂпѓЊпЇ£ўИўКвАђ вАЂпї£пЇ≥пїМЎ±вАђ вАЂпї£пЇОЎ°вАђ вАЂЎ£пЇІЎ±вАђ вАЂпї£пЇ≥пїМЎ±вАђ вАЂпїЯпї†Ў≤пѓЊЎ™вАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂпї£пЇ£Ў±ЎІЎ±вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂпїЧпѓЊпЇОЎ≥вАђ вАЂпї£пЇ£Ў±ЎІЎ±вАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂпїЯпЇЧпЇ≥пЇІпѓЊўЖвАђ вАЂЏЊпѓЊпЇЧЎ±вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпї£пЇОЎ°вАђ 1000 270 вАЂЎ≤пѓЊЎ™вАђ

- 6. ў£.вАЂЎІпїЯпї†вАђ вАЂЎ£пїІўИЎІЎєвАђ вАЂЏЊпї≤вАђ вАЂпї£пЇОвАђвАЂпїЧпѓЊпЇОпЇ≥пЃ≠пЇОвАђ вАЂЎЈЎ±ўВвАђ вАЂЏЊпї≤вАђ вАЂўИпї£пЇОвАђ вАЂЎ≤ўИпЇЯпЇФвАђ вАЂЏЊпї≤вАђ вАЂЎ£пїІўИЎІЎєвАђ вАЂпїЛЎѓўЗвАђ вАЂЎ•пїЯпї∞вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпЇЧпїШпЇ≥пѓЊўЕвАђ вАЂўИпѓЊпї£пїЫўЖвАђ: ў°.вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђвАЂЏЊпЇОўИвАђ вАЂЎІпїЯпї£ЎЈпї†ўВвАђвАЂЎІпїЯЎѓпѓЊпїІпЇОпї£пѓЊпїЫпѓЊпЇФвАђ)dynamics viscosity: (вАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпЇ£Ў±пїЫпЃЂвАђ вАЂпї£ўЖвАђ вАЂЎІпїЯпїІпЇОпЇЧпЇЯпЇФвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂЏЊпї≤вАђ вАЂпЇСпЇОпїЯЎ±пї£Ў≤вАђ вАЂпїЯпЃ≠пЇОвАђ вАЂўИпѓЊЎ±пї£Ў≤вАђ вАЂЎІпїЯпїШЎµвАђ вАЂпїЧўИўЙвАђ вАЂпЇСўИпЇЯўИЎѓвАђ)ќЉ(вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂўИпЇЧпїШпЇОЎ≥вАђ.вАЂпѓЊпЇ≥пї£пї∞вАђ вАЂўИЎІпїЯЎ∞ўКвАђpoise ўҐ.вАЂЎІпїЯпїЫпѓЊпїІпї£пЇОпЇЧпѓЊпїЫпѓЊпЇФвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ)kinematics viscosity: (вАЂпЇСпЇОпїЯЎ±пї£Ў≤вАђ вАЂпїЯпЃ≠пЇОвАђ вАЂўИпѓЊЎ±пї£Ў≤вАђvвАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂўИпЇЧпїШпЇОЎ≥вАђsвБД вАЂпѓЊпЇ≥пї£пї∞вАђ вАЂўИЎІпїЯЎ∞ўКвАђstokeвАЂЏЊпї≤вАђ вАЂЎІпїЯЎѓпѓЊпїІпЇОпї£пѓЊпїЫпѓЊпЇФвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пїКвАђ вАЂпїЛпїЉпїЧпЇЧпЃ≠пЇОвАђ вАЂЎ•пї£пЇОвАђ: вАЂўИЏЊпї≤вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂЎІпїЛпЇЧпї£ЎѓЎ™вАђ вАЂЎ±пЇЛпѓЊпЇ≥пѓЊпЃЂвАђ вАЂЎЈЎ±ўВвАђ вАЂпЇЫпїЉЎЂвАђ вАЂЏЊпїІпЇОўГвАђ: ў°.вАЂпїЯвАђ вАЂпЇЧЎ≤ЎѓЎІЎѓвАђ вАЂпїЫпї†пї£пЇОвАђ вАЂпЇ£пѓЊЎЂвАђ вАЂпї£пЇОпЇЛпїКвАђ вАЂпїУпї≤вАђ вАЂпї£пїРпї£ўИЎ±Ў©вАђ вАЂЎІпЇ≥ЎЈўИЎІпїІпЇФвАђ вАЂпїЯпЇЧЎѓўИпѓЊЎ±вАђ вАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯпїМЎ≤ўЕвАђ вАЂпї£пїМЎ±пїУпЇФвАђвАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂЎ≤ўИпЇЯпЃЂвАђ"вАЂЎІпїЯЎ≤пѓЊЎ™вАђ"вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓўЕвАђ вАЂпїЯпї†пЇЧЎѓўИпѓЊЎ±вАђ вАЂЎ£пїїЎ≤ўЕвАђ ўҐ.вАЂпї£пїШЎѓЎІЎ±ЏЊпЇОвАђ вАЂпї£пїМпї†ўИпї£пЇФвАђ вАЂўИпїЯпї£пЇ≥пЇОпїУпЇФвАђ вАЂпїЯпї£пЇОпЇЛпїКвАђ вАЂпЇ£ЎѓпѓЊЎѓпѓЊпЇФвАђ вАЂпїЫЎ±Ў©вАђ вАЂпїїпЇ£пЇЧЎ±ЎІўВвАђ вАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпї£пїМЎ±пїУпЃЂвАђLвАЂпїЫЎ±Ў©вАђ вАЂпЇСпЇИпЇ≥пїШпЇОЎЈвАђ вАЂпїІпїШўИўЕвАђ вАЂпЇ£пѓЊЎЂвАђ вАЂЎІпїєпїІпЇОЎ°вАђ вАЂпїЧпїМЎ±вАђ вАЂЎ•пїЯпї∞вАђ вАЂпїЯўИпЇїўИпїЯпЃ≠пЇОвАђ вАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпЇ£пЇ≥пЇОЎ®вАђ вАЂпѓЊпЇЧўЕвАђ вАЂпї£пїМпѓЊпїІпЃЂвАђ вАЂўИпїЯпї£пЇ≥пЇОпїУпЇФвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпЇ≥ЎЈпЇҐвАђ вАЂЎІпїЛпї†пї≤вАђ вАЂпї£ўЖвАђ вАЂпЇ£ЎѓпѓЊЎѓўЗвАђЎМвАЂпїУпїЫпї†пї£пЇОвАђ вАЂЎ£пїїЎ≤вАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпѓЊЎ≤ЎѓЎІЎѓвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂЎІЎ≤ЎѓЎІЎѓЎ™вАђвАЂЎІпїєпїІпЇОЎ°вАђ вАЂпїЧпїМЎ±вАђ вАЂЎ•пїЯпї∞вАђ вАЂЎІпїЯпїЫЎ±Ў©вАђ вАЂпїЯўИпЇїўИўДвАђ вАЂўЕвАђ ў£.вАЂЎІпїІпїЫпї†Ў±вАђ вАЂЎЈЎ±пїЧпЃЂвАђЎМвАЂпЇІпїЉўДвАђ вАЂпѓЊпїІпЇ≥пЇОЎ®вАђ вАЂЎІпїЯЎ∞ўКвАђ вАЂЎІпїЯпї£пЇОпЇЛпїКвАђ вАЂпї£ўЖвАђ вАЂпї£пїМпї†ўИпї£пЇФвАђ вАЂпїЫпї£пѓЊпЇФвАђ вАЂпїЯпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ£пїїЎ≤ўЕвАђ вАЂЎІпїЯЎ≤пї£ўЖвАђ вАЂпї£пїМЎ±пїУпЃЂвАђ вАЂпѓЊпЇЧўЕвАђ вАЂпЇІпїЉпїЯпЃ≠пЇОвАђ вАЂпї£ўЖвАђ вАЂпЇїпїРпѓЊЎ±Ў©вАђ вАЂЎ£пїІпЇСўИпЇСпЃЂвАђЎМвАЂЎІпїЯпЇСпЇЧЎ±ўИпїЯпѓЊпЇФвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЃЂвАђ вАЂпїЯпїШпѓЊпЇОЎ≥вАђ вАЂЎ£пїЯЎЈЎ±пѓЊпїШпЃЂвАђ вАЂЏЊЎ∞ўЗвАђ вАЂўИпїІпЇ≥пЇЧпЇІЎѓўЕвАђ"вАЂЎІпїЯпЇїпїІпЇОпїЛпѓЊпЇФвАђ вАЂЎІпїЯЎ≤пѓЊўИЎ™вАђ" ў§.вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂЏЊЎ∞ўЗвАђ вАЂпї£ўЖвАђ вАЂЎІпЇ≥пЇЧпїІпЇЧпЇОпЇЯпЃ≠пЇОвАђ вАЂпѓЊпЇЧўЕвАђ вАЂЎІпїЯпЇЧпї≤вАђ вАЂЎІпїїпЇ≥пЇЧпїІпЇЧпЇОпЇЯпЇОЎ™вАђ вАЂЏЊпї≤вАђ вАЂпї£пЇОвАђ вАЂўИпїІпїЉпЇ£ЎЄвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЇФвАђ вАЂпїЧпї†Ў™вАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ вАЂЎІЎ±пЇЧпїФпїМЎ™вАђ вАЂпїУпїЫпї†пї£пЇОвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпїЯЎ≤ўИпЇЯпЇФвАђ вАЂпїЛпї†пї∞вАђ вАЂпїЫпЇСпѓЊЎ±вАђ вАЂпЇЧпЇДпЇЫпѓЊЎ±вАђ вАЂпїЯпї†пЇ£Ў±ЎІЎ±Ў©вАђвАЂЎ£ўЖвАђвАЂЎѓЎ±пЇЯпЃЂвАђ вАЂЎІпїЯпЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎ≤пї£ўЖвАђ вАЂпї£пїКвАђ вАЂпїЛпїЫпЇ≥пї≤вАђ вАЂпЇЧпЇЧпїІпЇОпЇ≥Ў®вАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ ў•.вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂпїЛпї†пї∞вАђ вАЂЎІпїЯпї£Ў§пЇЫЎ±вАђ вАЂЎІпїЯпїМўИЎІпї£ўДвАђ вАЂпїІпЇОпїЧЎівАђ ў°.вАЂЎІпїЯпїШЎ±ЎІЎ°ЎІЎ™вАђ вАЂЎІпЇІЎ∞вАђ вАЂЎѓпїЧпЇФвАђвАЂпЇ≥пїЫЎ®вАђ вАЂЎ≤пї£ўЖвАђ вАЂўИвАђ вАЂпїЯпї†пЇ£Ў±ЎІЎ±Ў©вАђвАЂпїЯпї†пЇЧпЇЯпї£пѓЊпїКвАђ вАЂЎІпїЯЎѓўИЎ±ўВвАђ вАЂЎѓЎІпЇІўДвАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђвАЂпї£ўЖвАђвАЂЎІпїЯпї£пЃ≠вАђ вАЂЎІпїЯпїМўИЎІпї£ўДвАђвАЂпї£пЇФвАђвАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂпїУпї≤вАђвАЂпїЯпЃ≠пЇОвАђ вАЂўИЎІпїЯпїІпЇЧпЇОпЇЛпЇЮвАђ вАЂЎІпїЯпЇ£пЇ≥пЇОпЇСпЇОЎ™вАђ вАЂпїЛпї†пї∞вАђ вАЂпїЫпЇСпѓЊЎ±вАђ вАЂпЇЧпЇДпЇЫпѓЊЎ±вАђ ўҐ.вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓпї£пЇФвАђ вАЂЎІпїЈпЇЯпЃ≠Ў≤Ў©вАђ вАЂпї£пїКвАђ вАЂЎІпїЯЎЈпЇОпїЯЎ®вАђ вАЂпЇЧпїМпЇОпї£ўДвАђ вАЂўИЎЈЎ±пѓЊпїШпЇФвАђ вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпї£пЇ≥пЇЧпЇІЎѓўЕвАђ вАЂЎІпїЯпї£пЇ£Ў±Ў±вАђ вАЂЎѓпїЧпЇФвАђ ў£.вАЂпїЛпї†пї∞вАђ вАЂпїЧпЇОпЇЛпї£пЇФвАђ вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂпїїўЖвАђ вАЂЎІпїЯпЇЧпЇЯЎ±пЇСпЇФвАђ вАЂпїУпї≤вАђ вАЂпї£пЃ≠ўЕвАђ вАЂпїЛпЇОпї£ўДвАђ вАЂўИЎІпїЯпї£пЇОЎ°вАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпЇСпѓЊўЖвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ вАЂўИпЇїўИўДвАђ вАЂпї£Ў±ЎІпїЛпЇОЎ©вАђ вАЂЎІпїЈпЇ≥пЇОЎ≥вАђ вАЂЏЊЎ∞ЎІвАђвАЂЎІпїЯпїШвАђ вАЂЎІпЇІЎ∞вАђ вАЂпїУпї≤вАђ вАЂпЇІпї†ўДвАђ вАЂпїУпЇДўКвАђвАЂЎІпїЯпїІпЇЧпЇОпЇЛпЇЮвАђ вАЂпїЛпї†пї∞вАђ вАЂпѓЊЎ§пЇЫЎ±вАђ вАЂЎ±ЎІЎ°Ў©вАђ

- 7. ў¶.вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпЇ£пЇЯўЕвАђ вАЂпЇСпїШЎѓЎ±вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпЇ£пЇЯўЕвАђ вАЂЎІпЇ≥пЇЧпЇІЎѓЎІўЕвАђ вАЂпѓЊпЇЧўЕвАђ вАЂпїЯўЕвАђ вАЂпїЯпї£пЇОЎ∞ЎІвАђ вАЂўИЎІпїЯпї£пЇОЎ°вАђ вАЂЎІпїЯЎ≤пѓЊЎ™вАђ вАЂпЇІпЇїпЇОпЇЛЎµвАђ вАЂЎІпЇІпЇЧпїЉўБвАђ вАЂпЇСпЇ≥пЇСЎ®вАђ)вАЂЎІпїЯпїЫпЇЫпЇОпїУпЇФвАђЎМвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ(вАЂпЇСпЇОпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎІпїїпЇ£пЇЧпїФпЇОЎЄвАђ вАЂпїЛпї†пї∞вАђ вАЂпї£пїІпЃ≠пї£пЇОвАђ вАЂпїЫўДвАђ вАЂўИпїЧЎѓЎ±ўЗвАђ вАЂўИЎІпїЯпЇ≥пїМпЇФвАђ вАЂЎІпїЯпЇ£пЇЯўИўЕвАђ вАЂЏЊЎ∞ЎІвАђ вАЂпїЛпї†пї∞вАђ вАЂпЇ£пЇ≥Ў®вАђ вАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂўИЎІпїІпЇЧпїШпЇОўДвАђ вАЂўИЎІпїЯЎ≤пѓЊЎ™вАђ вАЂЎІпїЯпї£пЇОЎ°вАђ вАЂпЇСпѓЊўЖвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпїЛпї†пї£пѓЊпЇФвАђ вАЂўИЎІўЖвАђ ўІ.вАЂЎ±вАђвАЂЎІпїЯпїМпЇОпїЯпїШпЇФвАђ вАЂпЇ≥ўЕвАђвАЂпЇСпѓЊўЖвАђвАЂЎѓвАђвАЂўИвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎ±пЇЯпЇФвАђвАЂЎІпїІпїЫпї†Ў±вАђ вАЂпЇСўИпЇ£ЎѓЎІЎ™вАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпї£пѓЊўИпїЛпЇФвАђ вАЂЎ£пїЫпЇЫЎ±вАђ вАЂЎІпїЯпЇ≥пЇОпЇЛўДвАђ вАЂўИпѓЊпЇїпЇСпЇҐвАђ вАЂўИЎІпїЯЎѓпѓЊпїІпЇОпї£пѓЊпїЫпѓЊпЇФвАђ вАЂЎІпїЯпЇ£Ў±пїЫпѓЊпЇФвАђ вАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂпЇЧпїШўДвАђ ЎМвАЂЎІпїЯпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎ≤ЎІЎѓЎ™вАђ вАЂпїЫпї†пї£пЇОвАђ. вАЂЎІпїЯпЇЯЎ≤пѓЊпЇЛпї≤вАђ вАЂЎІпїЯпїМЎ≤ўЕвАђ вАЂЎІпїІпЇЧпїШпЇОўДвАђ вАЂпїЛпї†пї∞вАђ вАЂпЇЧЎЈпїРпї∞вАђ вАЂўИЎІпїЯпЇЧпї≤вАђ вАЂЎІпїЯпЇЯЎ≤пѓЊпЇЛпЇОЎ™вАђ вАЂпЇСпѓЊўЖвАђ вАЂЎІпїЯпЇЧпї£пЇОпЇ≥ўГвАђ вАЂпїЧўИўЙвАђ вАЂЎ•пїЯпї∞вАђ вАЂЎ∞пїЯўГвАђ вАЂпїУпї≤вАђ вАЂЎІпїЯпЇ≥пЇСЎ®вАђ вАЂпѓЊпїМўИЎѓвАђ вАЂпЇЧпїШпЇОвАђ вАЂпЇСпЇ≥пЇСЎ®вАђ ўЛвАЂпЇОвАђвАЂЎ£пѓЊпЇњвАђ вАЂўИЏЊЎ∞ЎІвАђ ЎМвАЂЎІпїЯпЇЯЎ≤пѓЊпЇЛпЇОЎ™вАђ вАЂЏЊЎ∞ўЗвАђ вАЂпЇСпѓЊўЖвАђвАЂпїЫпЇСпѓЊЎ±вАђ вАЂпЇСпЇЈпїЫўДвАђ вАЂЎІпїЯпЇЯЎ≤пѓЊпЇЛпЇОЎ™вАђ вАЂЎ±Ў®вАђ)вАЂпЇ£пЇЯўЕвАђ вАЂпЇїпїРЎ±вАђ вАЂпЇ≥пЇСЎ®вАђ вАЂпѓЊпїФпЇ≥Ў±вАђ вАЂЏЊЎ∞ЎІвАђ вАЂпЇСпЇОпїЯпїРпЇОЎ≤ЎІЎ™вАђ вАЂпї£пїШпЇОЎ±пїІпЇФвАђ вАЂЎІпїЯпЇ≥ўИЎІпЇЛўДвАђ.(вАЂўИпЇСпЇОпїЯпЇЧпЇОпїЯпї≤вАђ вАЂпЇЧпїШўДвАђ вАЂЎІпїЯпЇЯЎ≤пѓЊпЇЛпЇОЎ™вАђ вАЂпЇСпѓЊўЖвАђ вАЂЎІпїЯпЇЧпї£пЇОпЇ≥ўГвАђ вАЂпїЧўИўЙвАђ вАЂпїУпЇИўЖвАђ ЎМвАЂЎІпїЯпЇ≥пЇОпЇЛўДвАђ вАЂпЇЧпЇ≥пЇІпѓЊўЖвАђ вАЂпїЛпїІЎѓвАђ вАЂЎІпїЯпЇ≥пЇОпЇЛўДвАђ вАЂпїЯЎ≤ўИпЇЯпЇФвАђ вАЂпЇЧпїШпї†пѓЊўДвАђ вАЂЎ•пїЯпї∞вАђ вАЂпЇСпЇОпїЯпїІпЃ≠пЇОпѓЊпЇФвАђ вАЂпї£Ў§ЎѓпѓЊпЇФвАђ ЎМвАЂпЇСпѓЊпїІпЃ≠пЇОвАђ вАЂЎІпїЯпЇЧпЇЯпЇОЎ∞Ў®вАђ вАЂпїЧўИўЙвАђ вАЂпЇЧпїШўДвАђ. 0 2 4 6 8 10 12 14 16 0 5 10 15 20 25 30 35 вАЂЎІпїІпїЫпї†Ў±вАђвАЂпЇСўИпЇ£ЎѓЎІЎ™вАђвАЂЎІпїЯпї†Ў≤ўИпЇЯпЇФвАђ вАЂЎІпїїпЇЧЎ≤ЎІўЖвАђ вАЂпЇ£Ў±ЎІЎ±Ў©вАђ вАЂЎѓЎ±пЇЯпЇФвАђ