steam power plant

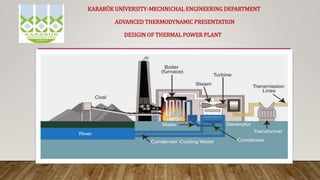

- 1. KARABÃK UNÄ°VERSITY-MECHNICHAL ENGINEERING DEPARTMENT ADVANCED THERMODYNAMIC PRESENTATION DESIGIN OF THERMAL POWER PLANT

- 2. Introduction Day by day increasing the demand on the energy from the industrial, manufactories and different customers, the price of the energy-producing is so hight because the energy-producing is depend on fossil fuel, and the price of the fossil fuel is so hight. The significant concern about the total dependence on fossil fuels for energy production. On the other hand, the combustion of fossil fuels causes harmful emissions for organisms such as carbon monoxide(co), nitrogen oxides(nox), etc. The growing demand for power has made the power plants of scientific interest, ,thermal power plant are converted the chemical energy in the fuel âcoalâ to thermal energy to raise the temperature of the liquid INSIDE THE TUBES IN THE BOILER then convert it to saturated steam to spin the blades of the turbine and generate electric energy in the generator.

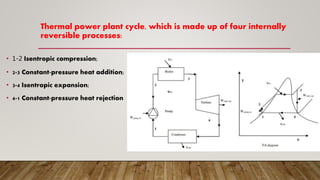

- 4. Thermal power plant cycle, which is made up of four internally reversible processes: âĒ 1-2 Isentropic compression; âĒ 2-3 Constant-pressure heat addition; âĒ 3-4 Isentropic expansion; âĒ 4-1 Constant-pressure heat rejection

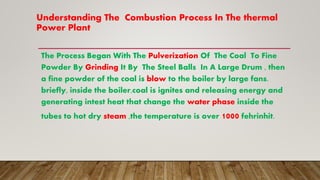

- 5. Understanding The Combustion Process In The thermal Power Plant The Process Began With The Pulverization Of The Coal To Fine Powder By Grinding It By The Steel Balls In A Large Drum , then a fine powder of the coal is blow to the boiler by large fans. briefly, inside the boiler,coal is ignites and releasing energy and generating intest heat that change the water phase inside the tubes to hot dry steam ,the temperature is over 1000 fehrinhit.

- 6. The Exchange Phase Of The Water Inside The Pipes Of The Boiler The boiler is the biggest parts and critical parts in the power plant and basically consist of five parts [burners, economizer, downcomer, water walls, steam drum]. In the beginning, The water is supplied into tubes in the boilers by feedwater pump, burners in the boiler are converted the chemical energy in the pulverization coal into thermal energy by the combustion process. After the combustion process, the flue gases are travels over the boiler and the economizer absorbs the heat from the flue gases and raising the temperature of the water in the tubes by this heat.

- 7. Separate The Water Droplet From The Steam The next stape is separate the water droplet from the steam in the âsteam drumâ, The resulting steam is pure and saturated vapor, the saturated steam can be fed back into the turbine.

- 8. MAIN COMPONENT OF BOILER IN THE STEAM POWER PLANT

- 9. BOILER EFFICINCEY Boiler efficiency = (ððĄððð ðððĄâððððĶ â ðððð ðĪððĄðð ðððĄâððððĶ) âðððĄ ðððð ððĒðð â 100% [Æ = ðð(â2ââ1) ððâ ðð â 100%] Mc : mass flow rate of the condenstate=feed water flow rate (kg/s) Qf : lower heating value of fuel (kj/kg) Mf : mass flow rate of fuel(kg/s) H1 :enthalpy of water after feed pump(kj/kg) H2 :enthalpy of saturated steam leaving the boiler (kj/kg)

- 10. TURBINES Turbine Is The Main Element In The Steam Power Plants And Normally Lies On The Heart Of The Steam Power Plant, Turbines Convert The Thermal Energy In The Steam To Mechanical Energy. The Mechanical Energy Can Rotate The Shaft Of The Turbine And Gain Useful Work Like Electricity.

- 11. UNDERSTANDING THE WORK OF THE TURBINE Basically, Turbine Consists Of Roter Shaft And Blades, Blades Have An Airfoil Shape, When The Higher Energy Fluid Passes Over Turbine Airfoil Shape Will Create Pressure Difference This Will Subsequently Generate A Lift Force And Generated Lift Force Will Rotate The Shaft Of Turbine Then Generate Electricity In The Generator.

- 13. Main Component Of Thermal Power Plant

- 14. Designing The Simple Power Plant In the next slides Designing the simple power plant and calculating the efficincey , work net , quality of the simple power plant cycle opearating on the simple ideal rankine cycle , steam enters the turbinenat 60 bar and 500 c and condesend in the condenser at a pressure of 0.1 bar

- 15. The Effect Of Boiler Pressure On The turbine work [KJ/kg]

- 16. The Effect Of Boiler Pressure On The Mass Flow Rate Of The Steam[kj/Kg.m]

- 17. The Effect Of Boiler Pressure On The Quality Of The Cycle

- 18. THE EFFECT OF BOILER PRESSURE ON THE HEAT ADD TO THE CYCLE[KJ/KG]

- 19. TABLE OF RESULTS Boiler pressure[ba r] Thermal Efficincey Work of turbine[kj/k g] Work net [kj/kg] Heat add [kj/kg] Quality of the cycle 10 0.30 1018 1017 3286 0.94 15.56 0.32 1079 1017 3279 0.92 21.11 034 1120 1118 3272 0.90 26.67 0.351 1150 1147 3266 0.88 32.22 0.359 1173 1170 3259 0.87 37.78 0.367 1192 1189 3252 0.86 43.12 0.371 1208 1204 3245 0.85 48.89 0.375 1222 1217 3238 0.84 54.44 0.379 1223 1228 3231 0.8379 60 0.383 1443 1237 3224 0.8309

- 20. IMPROVEMENT EFFICIENCY OF THERMAL POWER PLANT Improvement efficiency of the thermal power plant by the increase the average temperature at which heat is transferred to the water in the tubes in the boiler, or decrease the average temperature at which heat is rejected from the fluid in the condenser.

- 21. 1. Improvement efficiency of thermal power plant by Increasing The Boilerâs Pressure Increasing The operating Pressure which automatically raises the temperature at which boiling takes place, this is, the higher tempterature of the steam is more efficinent of the thermal power plant cycle. Increasing the boiler pressure increases the thermal efficiency of the thermal power plant cycle, but it also increases the moisture content of the steam to undesirable levels.

- 22. 2. Improvement Efficiency Of Thermal Power Plant By Lowering The Condenser Pressure Lowering operating presssre of the condenser automatically lowers the temperature of the steam , and thus the temperature at which heat rejected.That Clear in the figure The Wnet is increase when lowering the condenser pressure .

- 23. 3. Improvement Efficiency Of Thermal Power Plant By Superheating The effect of the super heating on the steam power plant performance illstarted on the T-S digram, the pruple arie represent the increase of Wnet

- 24. 4. Improvement Efficiency Of Thermal Power Plant By Reheat Process Increasing the boiler pressure increases the thermal efficiency of the Rankine cycle, but it also increases the moisture content of the steam to undesirable levels. Expand the steam in the turbine in two stages, and reheat it in between. It can decrease the excessive moisture problem in turbines. . The purpose of the reheat cycle is to reduce the moisture content of the steam at the final stages of the expansion process.

- 25. 5. Improvement Efficiency Of Thermal Power Plant By Regenerative process To transfer heat to the feed-water from the expanding steam in a counter-flow heat exchanger built into the turbine, that is, to use regeneration. A practical regeneration process in steam power plants is accomplished by extracting/bleeding the steam from the turbine at various points. Regeneration not only improves cycle efficiency.It also helps control the large volume flow rate of the steam at the final stages of the turbine.

- 26. RESULT AND CONSULUTION After simulation of the steam power plant by a program âEESâ obtained the results shown below: 1. When increasing the pressure of the boiler increases the efficiency of the plant and increases the work net Wnet of the station, and reduce the heat added Qadd and reduce the quality of the station. 2. When decreasing the pressure of condenser increase the efficiency of the plant and increases the work net Wnet of the station, and reduce the heat added Qadd and reduce the quality of the station. 3.When reheated the steam again the efficiency of the plant and increases the work net Wnet of the station, and reduce the heat added Qadd and reduce the quality of the station.

- 27. REFERANCE [1]Energy and exergy analyses of thermal power plants: A review âĒ S.C. Kaushika, V. Siva Reddya,â, S.K. Tyagib [2]Thermodynamic analysis of reheat cycle steam power plants Ibrahim Dincer* and Husain Al-Muslim [3]An Approach to Analyse Energy and Exergy âĒ Analysis of Thermal Power Plants: A Review âĒ Vundela Siva Reddy1, Subhash Chandra Kaushik1, Sudhir Kumar Tyagi2, Naraya Lal Panwar1

- 28. Thank you for listin to me

![The Exchange Phase Of The Water Inside The Pipes Of

The Boiler

The boiler is the biggest parts and critical parts in the power

plant and basically consist of five parts [burners, economizer,

downcomer, water walls, steam drum]. In the beginning, The

water is supplied into tubes in the boilers by feedwater pump,

burners in the boiler are converted the chemical energy in the

pulverization coal into thermal energy by the combustion

process. After the combustion process, the flue gases are travels

over the boiler and the economizer absorbs the heat from the

flue gases and raising the temperature of the water in the tubes

by this heat.](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-6-320.jpg)

![BOILER EFFICINCEY

Boiler efficiency =

(ððĄððð ðððĄâððððĶ â ðððð ðĪððĄðð ðððĄâððððĶ)

âðððĄ ðððð ððĒðð

â 100% [Æ =

ðð(â2ââ1)

ððâ ðð

â

100%]

Mc : mass flow rate of the condenstate=feed water flow rate (kg/s)

Qf : lower heating value of fuel (kj/kg)

Mf : mass flow rate of fuel(kg/s)

H1 :enthalpy of water after feed pump(kj/kg)

H2 :enthalpy of saturated steam leaving the boiler (kj/kg)](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-9-320.jpg)

![The Effect Of Boiler Pressure On The turbine work

[KJ/kg]](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-15-320.jpg)

![The Effect Of Boiler Pressure On The Mass Flow Rate Of

The Steam[kj/Kg.m]](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-16-320.jpg)

![THE EFFECT OF BOILER PRESSURE ON THE HEAT ADD TO

THE CYCLE[KJ/KG]](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-18-320.jpg)

![TABLE OF RESULTS

Boiler

pressure[ba

r]

Thermal

Efficincey

Work of

turbine[kj/k

g]

Work net

[kj/kg]

Heat add

[kj/kg]

Quality of

the cycle

10 0.30 1018 1017 3286 0.94

15.56 0.32 1079 1017 3279 0.92

21.11 034 1120 1118 3272 0.90

26.67 0.351 1150 1147 3266 0.88

32.22 0.359 1173 1170 3259 0.87

37.78 0.367 1192 1189 3252 0.86

43.12 0.371 1208 1204 3245 0.85

48.89 0.375 1222 1217 3238 0.84

54.44 0.379 1223 1228 3231 0.8379

60 0.383 1443 1237 3224 0.8309](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-19-320.jpg)

![REFERANCE

[1]Energy and exergy analyses of thermal power plants: A review

âĒ S.C. Kaushika, V. Siva Reddya,â, S.K. Tyagib

[2]Thermodynamic analysis of reheat cycle steam power plants

Ibrahim Dincer* and Husain Al-Muslim

[3]An Approach to Analyse Energy and Exergy

âĒ Analysis of Thermal Power Plants: A Review

âĒ Vundela Siva Reddy1, Subhash Chandra Kaushik1, Sudhir Kumar Tyagi2, Naraya Lal

Panwar1](https://image.slidesharecdn.com/presentation2-190430123932/85/steam-power-plant-27-320.jpg)