Steamfitter Union DACUM Research Chart

- 1. DACUM Research Chart for Steamfitter DACUM Panel Representing 291 years of experience Doug Armstrong, Executive Director Mechanical Contractors Association of NWPA Erie PA Adam Artise, Journeymen Steamfitter Scobell Co. Inc., North East, PA Paul D. Case, Fabrication Shop Supervisor William T. Spaeder Co., Inc., Girard, PA Dale Glavin, Training Director Steamfitters Local Union 449, Pittsburgh, PA Rob Kubiak, Piping Division Manager Rabe Environmental Systems, Erie, PA Dave Ochalek, Instructor/ Steam fitter Erie Training Center, Oil City, PA Thomas R. Staab, Retired Instructor Espyville, PA Jeremy Stafford, Steamfitter Journeyman Bortnick Construction, Saegertown, PA Carl Sutliff, Piping Division Manager Bortnick Construction, Inc., Linesville, PA Brad Tisdale, Training Director Steamfitters Local Union 449, Erie, PA Facilitator Jan Kennerknecht, DACUM Facilitator Edinboro, PA Produced for Steamfitters Local Union 449 Produced by 12860 Kline Road Edinboro, PA 16412 November 3-4, 2016

- 2. DACUM Research Chart for Steamfitter Application of these tasks will vary based on assigned work. Duties Tasks Manage Project Documentation Implement Safety Procedures A A-1 Provide worker certifications to customers A-2 Verify project blueprints A-3 Modify project blueprints A-4 Provide current as-built blueprints A-5 Submit work hours and details B A-6 Manage scope of work A-7 Document change orders A-8 Verify use of specified materials and equipment A-9 Verify welding procedures and qualifications A-10 Maintain SDS A-11 Document percentage of completed work A-12 Request daily permits (e.g., hot work, confined space, line breaks) A-13 Document schedule revisions A-14 Relay company standards to employees (e.g., employer’s, customer’s) A-15 Maintain inspection records (e.g., welds, pressure tests) A-16 Perform lock out/tag out procedure A-17 Complete accident report A-18 Maintain tool inventory list A-19 Submit intent to install documentation A-20 Report non- compliance of building codes A-21 Inspect equipment and materials for damage B-1 Utilize PPE B-2 Utilize SDS B-3 Evacuate work site B-4 Monitor employee safety B-5 Provide emergency resources, (e.g., phone numbers, first aid kits) B-6 Barricade dangerous work areas B-7 Provide fire watch assistance B-8 Participate in safety trainings (e.g., First Aid, Confined Space, Fall Protection) B-9 Identify hazardous materials B-10 Complete job hazard analysis B-11 Maintain safe work area B-12 Maintain equipment safety

- 3. DACUM Research Chart for Steamfitter Application of these tasks will vary based on assigned work. Duties Tasks Participate in Technical Training C C-1 Obtain welding certifications (e.g., UA21, UA63, UA41) C-2 Obtain OSHA certifications (e.g., 10 Hour, 30 Hour) C-3 Obtain ICRA 8 certification C-4 Obtain First Aid/CPR certification C-5 Obtain aerial lift certification C-6 Obtain fork lift certification C-7 Obtain industrial rigging certifications (e.g., EPRI) C-8 Obtain crane signal certification C-9 Obtain respirator fit test certification C-10 Obtain confined space certification C-11 Obtain brazing certification C-12 Obtain medical gas certification C-13 Obtain back- flow certification C-14 Obtain valve repair certification C-15 Obtain industrial instrumentation certification (e.g., fluid flow, leveling) C-16 Mentor steamfitter apprentices D Manage Job Site D-1 Coordinate job mobilization (e.g., trailer placement, utility locations, fabrication areas) D-2 Coordinate work with other trades D-3 Project two- week task completion D-4 Order project tools D-5 Order project materials D-6 Schedule deliveries of materials, tools and equipment D-7 Set up daily work plan D-8 Transport industrial equipment D-9 Manage project manpower levels D-10 Supervise project manpower D-11 Evaluate job progress D-12 Maintain job site cleanliness D-13 Maintain project tools D-14 Maintain project equipment D-15 Participate in job meetings

- 4. DACUM Research Chart for Steamfitter Application of these tasks will vary based on assigned work. Duties Tasks D-16 Address employee job concerns E Conceptualize Systems Layout E-1 Check prints and specifications E-2 Review project addendums E-3 Review project submittals E-4 Participate in field condition walk through E-5 Submit an RFI E-6 Coordinate systems layout with other trades E-7 Modify piping layout E-8 Develop isometric/CAD drawings E-9 Evaluate hanger layout E-10 Evaluate tie in requirements F Fabricate System Components F-1 Review isometric drawings F-2 Segment fabrication drawings F-3 Identify specified fabrication materials F-4 Establish pipe joining method F-5 Determine QC requirements F-6 Receive fabrication materials F-7 Verify fabrication materials F-8 Cut fabrication materials F-9 Prep fabrication materials (e.g., cleaning, beveling) F-10 Glue pipe and fittings F-11 Assemble mechanical joints (e.g., Lokring, ProPress, flaring) F-12 Thread pipes and rods F-13 Perform soldering techniques F-14 Perform brazing techniques F-15 Perform bolt-up process F-16 Groove pipe joints F-17 Perform plastic fusion techniques F-18 Perform GMAW F-19 Perform GTAW F-20 Perform FCAW F-21 Perform SMAW F-22 Bend tubing systems

- 5. DACUM Research Chart for Steamfitter Application of these tasks will vary based on assigned work. Duties Tasks G Install System Components G-1 Demo existing system G-2 Install systems supports (e.g., hangers) G-3 Make piping penetrations G-4 Rig system components G-5 Install mechanical equipment (e.g., pumps, boilers, chillers) G-6 Install piping systems G-7 Patch and seal system penetrations G-8 Inspect piping installation G-9 Pressure test piping G-10 Flush piping systems G-11 Evacuate piping system G-12 Purge piping systems G-13 Fill piping system G-14 Label piping systems G-15 Tag system valves G-16 Commission mechanical systems G-17 Balance piping system H Facilitate Customer Service H-1 Meet regularly with customer H-2 Build customer rapport H-3 Solicit customer input H-4 Respond to customer concerns H-5 Provide energy/labor savings suggestions to customers H-6 Conduct customer training (e.g., valve location, boiler operation) H-7 Ensure final project site clean-up

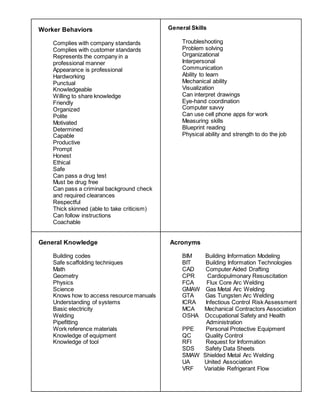

- 6. Worker Behaviors Complies with company standards Complies with customer standards Represents the company in a professional manner Appearance is professional Hardworking Punctual Knowledgeable Willing to share knowledge Friendly Organized Polite Motivated Determined Capable Productive Prompt Honest Ethical Safe Can pass a drug test Must be drug free Can pass a criminal background check and required clearances Respectful Thick skinned (able to take criticism) Can follow instructions Coachable General Skills Troubleshooting Problem solving Organizational Interpersonal Communication Ability to learn Mechanical ability Visualization Can interpret drawings Eye-hand coordination Computer savvy Can use cell phone apps for work Measuring skills Blueprint reading Physical ability and strength to do the job General Knowledge Building codes Safe scaffolding techniques Math Geometry Physics Science Knows how to access resource manuals Understanding of systems Basic electricity Welding Pipefitting Work reference materials Knowledge of equipment Knowledge of tool Acronyms BIM Building Information Modeling BIT Building Information Technologies CAD Computer Aided Drafting CPR Cardiopulmonary Resuscitation FCA Flux Core Arc Welding GMAW Gas Metal Arc Welding GTA Gas Tungsten Arc Welding ICRA Infectious Control Risk Assessment MCA Mechanical Contractors Association OSHA Occupational Safety and Health Administration PPE Personal Protective Equipment QC Quality Control RFI Request for Information SDS Safety Data Sheets SMAW Shielded Metal Arc Welding UA United Association VRF Variable Refrigerant Flow

- 7. Trends  You can do more with less now. Technology has resulted in fewer employees needed.  There is a larger need for foremen today.  MCA information may not be getting to the individual steamfitters.  Pipe joining methods have changed greatly. There are more options now.  Safety is a bigger focus now.  Quality is a big focus, resulting in more work hours.  Jobs are constructed on paper before being built in the field. (Auto CAD, Laser, GPS)  Robots are being used to set up hangers.  Three dimensional views on computers are being used to develop working drawings.  Cell phone apps can now be used to calculate rise/fall.  Computer speeds are doubling every 18 months.  Computer programs are evolving into more sophisticated products, requiring updating for employees and instructors. Concerns  A lot of talent is being overlooked for workers who want to advance in their career.  There should be money set aside for training foremen and supervisors, like government programs.  Motivation of workers is a concern.  We need to sponsor more foreman training.  Not all who attend supervisor training have the mind-set or personality to serve in that role.  CAD drawing, BIM, BIT should be incorporated into training.  Instructors need Blackboard training.  Professionalism is slipping in some areas, such as pride in work, respect of owner’s property  There should be additional incentives for helping workers achieve certifications.  Some offered trainings have been cancelled due to low enrollment.  Sometimes job requirements come on so fast that you don’t have time to get additional training or certification required. A “look ahead” by agents would be helpful.  Out of town workers are taking jobs- we need more qualified workers.  The number of apprentices bringing brought in aren’t keeping up with retirement.  Retention of apprentices is a concern.  New apprentices need challenging tasks to retain motivation.  We need to enforce apprenticeship standards. You must master the skills to advance.  Skill level verification process needs to be reviewed. This could be done each year of the apprenticeship program, in increments.  Opportunities must be varied for apprenticeship placements/training. Detailed apprentice cards (contract reports) could provide information for ensuring adequate opportunities.

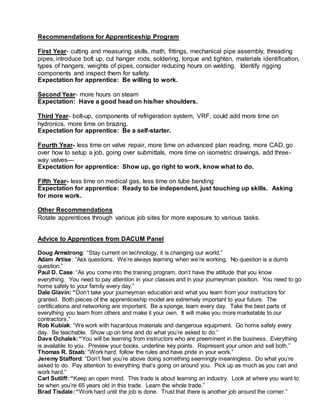

- 8. Recommendations for Apprenticeship Program First Year- cutting and measuring skills, math, fittings, mechanical pipe assembly, threading pipes, introduce bolt up, cut hanger rods, soldering, torque and tighten, materials identification, types of hangers, weights of pipes, consider reducing hours on welding. Identify rigging components and inspect them for safety. Expectation for apprentice: Be willing to work. Second Year- more hours on steam Expectation: Have a good head on his/her shoulders. Third Year- bolt-up, components of refrigeration system, VRF, could add more time on hydronics, more time on brazing. Expectation for apprentice: Be a self-starter. Fourth Year- less time on valve repair, more time on advanced plan reading, more CAD, go over how to setup a job, going over submittals, more time on isometric drawings, add three- way valves— Expectation for apprentice: Show up, go right to work, know what to do. Fifth Year- less time on medical gas, less time on tube bending Expectation for apprentice: Ready to be independent, just touching up skills. Asking for more work. Other Recommendations Rotate apprentices through various job sites for more exposure to various tasks. Advice to Apprentices from DACUM Panel Doug Armstrong: “Stay current on technology, it is changing our world.” Adam Artise: “Ask questions. We’re always learning when we’re working. No question is a dumb question.” Paul D. Case: “As you come into the training program, don’t have the attitude that you know everything. You need to pay attention in your classes and in your journeyman position. You need to go home safely to your family every day.” Dale Glavin: “Don’t take your journeyman education and what you learn from your instructors for granted. Both pieces of the apprenticeship model are extremely important to your future. The certifications and networking are important. Be a sponge, learn every day. Take the best parts of everything you learn from others and make it your own. It will make you more marketable to our contractors.” Rob Kubiak: “We work with hazardous materials and dangerous equipment. Go home safely every day. Be teachable. Show up on time and do what you’re asked to do.” Dave Ochalek:“You will be learning from instructors who are preeminent in the business. Everything is available to you. Preview your books, underline key points. Represent your union and sell both.” Thomas R. Staab: “Work hard, follow the rules and have pride in your work.” Jeremy Stafford: “Don’t feel you’re above doing something seemingly meaningless. Do what you’re asked to do. Pay attention to everything that’s going on around you. Pick up as much as you can and work hard.” Carl Sutliff: “Keep an open mind. This trade is about learning an industry. Look at where you want to be when you’re 65 years old in this trade. Learn the whole trade.” Brad Tisdale:“Work hard until the job is done. Trust that there is another job around the corner.”

![din_CVM2[2]](https://cdn.slidesharecdn.com/ss_thumbnails/de652985-54a6-40ee-afe5-0c159c0c1ce3-150704055125-lva1-app6891-thumbnail.jpg?width=560&fit=bounds)