Steel classification

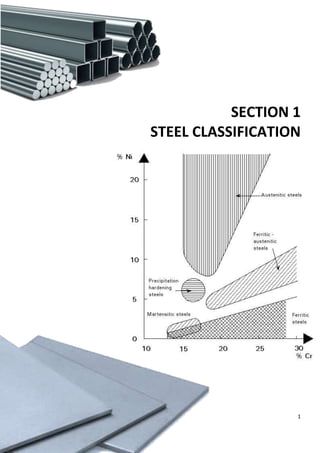

- 1. 1 IWE T1.4-2017 Welding Qualification Problems SECTION 1 STEEL CLASSIFICATION

- 2. 2 IWE T1.4-2017 Welding Qualification Problems

- 3. 3 IWE T1.4-2017 Welding Qualification Problems SECTION 1-1 HIGH ALLOW STEEL CLASSIFICATION Introduction There are three general classes of high-alloy steels: 1. Maraging Steels, 2. Nickel-Cobalt Alloy Steels, And 3. Austenitic Manganese Steels. 1- MARAGING STEELS Maraging steels are a class of iron-nickel alloys that are strengthened by precipitation of one or more intermetallic compounds in a matrix that essentially is carbon- free martensite. In addition to nickel, these steels generally contain molybdenum, cobalt, and smaller amounts of titanium and aluminum. Example of use of maraging steel (A579 GRAD 72)

- 4. 4 IWE T1.4-2017 Welding Qualification Problems 1-1 Chemical Properties 1-2 Physical Properties 1-3 Mechanical Properties

- 5. 5 IWE T1.4-2017 Welding Qualification Problems 2- NICKEL-COBALT STEELS The nickelâcobalt steels are premium alloy steels known for high strength, fracture toughness, and good weldability. The primary applications for these alloys are in aerospace and defense structures, including landing gear, armor plate, gears, dies, fasteners, and bearings. The nickel-cobalt steels provide an alternative to maraging steels for achieving ultra- high strength. They provide this ultra-high strength by virtue of precipitation of extremely fine alloy carbides instead of by precipitation of intermetallic compounds. 2-1 Chemical Properties 2-2 Mechanical Properties Tensile strengths for this class of alloys can range from approximately 1240 MPa to 1930 MPa, with fracture toughness ranging from over 176 MPa âm for low strength alloys, to 110 MPa âm for the higher strength alloys. ï§ K91472 and K91283 alloys are considered quenched-and-tempered alloys. ï§ K92571 and K92580 are secondary or precipitation hardening martensitic steels. All the alloys in this class exhibit good hardenability. For example, the K91283 alloy can be fully hardened in section thicknesses up to 150 mm The K92571 and K92580 alloys can be fully hardened in even greater thicknesses. The K91472 and K91283 (HP9-4-20 and HP9-4-30) alloys originally were produced by vacuum induction melting/vacuum arc re-melting (VIM/VAR), although they are also produced by electric furnace-argon oxygen- decarburization (EF-AOD) followed by VAR processing. The K92571 (AF 1410) and K92580 (also known by the trade name, AerMet 100) alloys generally are produced by VIM/VAR processing. Due to the cobalt and nickel contents and complex primary production routes, the nickel- cobalt steels are relatively expensive. Depending on the specific grade, nickel cobalt steels are available in billet, bar, rod, plate, strip, and sheet, although due to the required re-melting processes, the most commonly available forms are forging billet, bar, and plate.

- 6. 6 IWE T1.4-2017 Welding Qualification Problems 3- AUSTENITIC MANGANESE STEELS Austenitic manganese steels are characterized by good strength, ductility, and wear resistance and have rapid work-hardening characteristics. They may have yield strengths of only 345 MPa to 415 MPa in the solution-annealed condition; however, surface deformation by hammering, rolling, or any other cold-work process will raise the yield strength to provide a hard surface with a tough core structure. The manganese content generally ranges from 11% to 14%, and the carbon content generally ranges from 0.7% to 1.4%. 3-1 Chemical Properties 3-2 Physical Properties

- 7. 7 IWE T1.4-2017 Welding Qualification Problems 3-3 Mechanical Properties A few of the many applications of high-alloy steel are represented by classic examples of weldments used in the fabrication of a solid-fuel motor chamber from maraging steel, the welding of a K92580 tubular steel bicycle, and weldments used in manganese steel castings of railroad accessories. 4- CONCLUSION The high-alloy steels discussed above contain more than about 10% total alloying elements, and in many cases, more than 25% total alloy content. Thus, by composition and alloy expense alone, these materials are costly. In addition to this cost, ultra-high strength steels generally require vacuum processing, special control of impurities, and multiple-step heat treatment to develop the full potential for strength and toughness. These metals typically are only used in applications requiring a special combination of strength and toughness. As a result, the typical quality levels generally used for most welding fabrications may not be adequate to maintain the superior properties required for the applications for which these type steels would be selected. That is, the quality requirements carry through the full range of welding fabrication, from weld preparation and cleanliness, to gas purity and final inspections. Consequently, these materials generally are specified only for specialized applications when the property needs of the application warrant the additional costs associated with the purchase and fabrication. The weldability of these steels generally is excellent, with little or no preheat required. The steels that rely on the precipitation-hardening mechanism, such as some of the Ni- Co steels and the maraging steels, require special consideration, especially with respect to heat input. The limitation of low heat input that is often necessary for these materials limits productivity, especially if compared to low-alloy, high-strength steels, and stainless steels. However, when required for critical applications, properly fabricated weldments of these high-alloy steels provide functional and successful service. In contrast to the ultra-high-strength steels, the austenitic manganese steels described require care only to avoid overheating the steel and to avoid hot cracking during welding. Otherwise, they are relatively simple to weld, and have many welding characteristics in common with austenitic stainless steels.

- 8. 8 IWE T1.4-2017 Welding Qualification Problems SECTION 1-2 STAINLESS STEELS 1- INTRODUCTION Stainless steels are alloy steels with a nominal chromium (Cr) content of at least 11 weight percent (wt %), with or without other alloy additions. The oxidation and corrosion resistance of these alloy steels are attributed to the presence of a passive chromium-rich oxide film on the surface. The chromium-rich oxide can be damaged, but will quickly reform if oxygen is available. When exposed to conditions that damage the passive oxide film, stainless steels are subject to corrosive attack. The rate at which a stainless steel develops a passive film in the atmosphere depends on its chromium content. Polished stainless steels remain bright and tarnish-free under most atmospheric conditions. Exposure to elevated temperatures increases the thickness of the oxide film. 2- GENERAL CATEGORIES OF STAINLESS STEELS 1. Austenitic stainless steel FCC 2. Ferritic stainless steel BCC 3. Martensitic stainless steel BCT 4. Duplex stainless steel FCC and BCC 5. PH stainless steel (1-2-3-4 strengthened via precipitation hardening)

- 9. 9 IWE T1.4-2017 Welding Qualification Problems 3- MARTENSITIC STAINLESS STEELS: In most case P No 6 Martensitic stainless are essentially iron-chromium-carbon alloys with nominally 11.5% to 18% chromium and are hardenable by appropriate heat treatments. The martensitic stainless steels can be grouped into ï§ Martensitic stainless steel 12 % chromium, ï§ Martensitic stainless steel higher chromium ï§ Martensitic stainless steel low-carbon C < 0.2 ï§ Martensitic stainless steel medium carbon 0.2 < C < 0.5 used in steam turbines, gas turbines and jet engines ï§ Martensitic stainless steel high-carbon C > 0.5 are employed for gears, valves, shafts, cams and ball bearings. ï§ Super-martensitic stainless steels: Cr 11.5-13%, Ni 1.5-7%, Mo <2.5%, C<0.01 %. Classified into three grades according to corrosion resistance and toughness: 1. Lean grades with Ni < 4 % and little or no Mo additions 2. Medium grades with Ni of 4.5% to 5% and Mo < 1.5 % 3. High grades, with Ni > 4 % and Mo 2 % to 2.5 %. The Martensitic stainless steels exhibit: ï§ Moderate corrosion resistance, oxidation resistance, strength at service temperatures up to about 590°C, ï§ Ability to develop a wide range of mechanical properties, and ï§ Relatively low cost. Example: SA182 Grad F6 For forging (flange) **** SA240 Type 410 - S41500 - 429 For plate SA268 TP410 âS41500 âTP429 For seamless and welded tube *** SA276 TP410 For bar âĶ

- 10. 10 IWE T1.4-2017 Welding Qualification Problems Compositions of standard Martensitic stainless steels

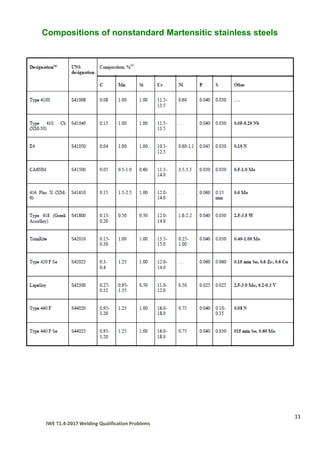

- 11. 11 IWE T1.4-2017 Welding Qualification Problems Compositions of nonstandard Martensitic stainless steels

- 12. 12 IWE T1.4-2017 Welding Qualification Problems 4- FERRITIC STAINLESS STEELS: In most case P No 7 Ferritic stainless steels are iron-chromium-carbon alloys containing 11% to 30% chromium, along with other ferrite stabilizers, such as molybdenum, aluminum, niobium, or titanium. Ferritic stainless steels exhibit ï§ Good ductility ï§ Good resistance to stress corrosion cracking, pitting, and crevice corrosion. ï§ Toughness levels of these steels decrease at lower temperatures The ferritic stainless steels can be grouped into ï§ Ferritic stainless steels Low chromium (~11%), such as Type 409, are used extensively in automotive exhaust systems. ï§ Ferritic stainless steel intermediate chromium (16% to 18%) are often utilized in food handling and automotive trim applications. ï§ Super-ferritic stainless steels high chromium and additions of molybdenum are employed in applications that require high levels of corrosion and oxidation resistance such as heat exchangers and piping systems for seawater. Example: SA182 F430 For forging (flange) SA240 Type 405/409/430/439/S43932/S44400 For plate SA268 TP405 âS40800âTP409-TP430-TP439-TP430Ti-18Cr-2Mo For seamless and welded tube âĶ

- 13. 13 IWE T1.4-2017 Welding Qualification Problems Compositions of standard Ferritic stainless steels

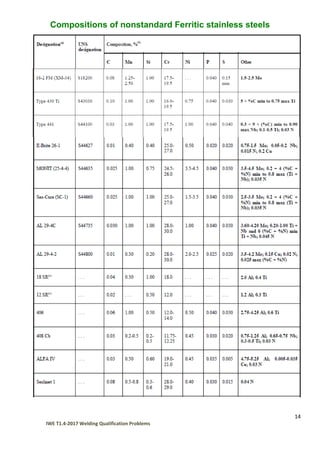

- 14. 14 IWE T1.4-2017 Welding Qualification Problems Compositions of nonstandard Ferritic stainless steels

- 15. 15 IWE T1.4-2017 Welding Qualification Problems 5- AUSTENITIC STAINLESS STEELS In most case P No 8 Austenitic stainless steels are the most widely used stainless steels of all the types. Austenitic stainless steels exhibit ï§ Good corrosion resistance ï§ Excellent ductility ï§ High toughness ï§ Good strength ï§ Excellent cryogenic properties ï§ Good strength and oxidation resistance at high temperatures The austenitic stainless steels contain: ï§ Cr + Ni + Mn + Si > 25% ï§ Cr > 16% The austenitic stainless steels can be grouped into: ï§ CAST ALLOYS ï§ Wrought alloys: - Fe-Cr-Mn-N: starting with 2, such as 201. - Fe-Cr-Ni-C: starting with 3, such as 304. ïĻSuffix N: addition of nitrogen to increases the YS and the stability of the austenite. ïĻSuffix H: high carbon content for high-temperature strength. ïĻSuffix L: Low-carbon variations. ïĻSuffix Se: Increasing of selenium to Improved machinability ïĻSuffix B: Increasing Silicon to improves scaling resistance at elevated temperatures

- 16. 16 IWE T1.4-2017 Welding Qualification Problems

- 17. 17 IWE T1.4-2017 Welding Qualification Problems Compositions of standard Austenitic stainless steels

- 18. 18 IWE T1.4-2017 Welding Qualification Problems

- 19. 19 IWE T1.4-2017 Welding Qualification Problems

- 20. 20 IWE T1.4-2017 Welding Qualification Problems 6- DUPLEX STAINLESS STEELS In most case P No 10H Duplex stainless steels (DSS) are two-phase alloys. They are based on the Fe-Cr-Ni-N system and are characterized by low carbon contents with additions of molybdenum, nitrogen and copper. They exhibit ï§ Higher strength ï§ Better resistance to stress corrosion cracking (SCC) and pitting than austenitic stainless steels; ï§ Better toughness compared to Ferritic stainless steels. These steels are widely used in paper, oil, gas and petrochemical industries.

- 21. 21 IWE T1.4-2017 Welding Qualification Problems 7- PRECIPITATION-HARDENING STAINLESS STEELS Precipitation-hardenable (PH) stainless steels (also known as age-hardening stainless steels) can be heat-treated to develop relatively high strengths. Strengthening of PH stainless steels is achieved primarily by the formation of sub-micron precipitates that impede dislocation motion. This strengthening component may also be coupled with the formation of martensite in some types of PH stainless steels. These steels have good corrosion and oxidation resistance without loss of ductility, and have fracture toughness values comparable to conventional steels with comparable strength levels. In general, PH stainless steels offer a combination of improved strength and corrosion resistance relative to martensitic stainless steels. One common application of PH stainless steels involves landing gear hardware.