Sterilization techniques

- 1. STERILIZATION METHODS BY- GOPAL M KUMBHANI M.SC BIOTECHNOLOGY1/18/2019 1

- 2. ’üČ Contents:- ’āś what is sterilization? ’āś History of sterilization ’āś Methods of sterilization ’āś Physical method ’āś Chemical method ’āś Filtration (mechanical method) method ’āś Refrences 1/18/2019 2

- 3. WHAT IS STERILIZATION? ’āśSterilization can be defined as a process by which all viable forms of micro-organisms(such as fungi, bacteria, viruses) are removed or destroyed. ’āśMicro organisms are present at everywhere. Since they cause contamination, infection, and decay, it becomes necessary to remove or destroy them from materials or from areas. ’āśSterilization procedures used is should be simple but effective and of relatively short duration. 1/18/2019 3

- 4. HISTORY OF STERILIZATION ’āśLOUIS PASTEUR of France was among the first to use sterilization techniques, he developed the steam sterilization, hot air oven and the autoclave. Pasteurization was a method developed by him to rid of bacilli from milk. ’āśJOSEPH LISTER, applied PasteurŌĆÖs work and introduced antiseptic technique in surgery(1867). He is the father of antiseptic surgery. 1/18/2019 4

- 5. METHODS OF STERILIZATION (1)Physical (2)Chemical (3)Filtration (Mechanical) 1/18/2019 5

- 6. ŌĆó Physical methods 1) Sunlight 2) Drying 3) Heat:- i) Moist heat ii) Dry heat 4) Radiation 1/18/2019 6

- 7. 1) Sun light - It is responsible for spontaneous sterilization in natural conditions. ’āś In tropical countries, the sunlight is more effective in killing germs due to combination of ultraviolet rays and heat. ’āśBy killing bacteria suspended in water, sunlight provides natural method of disinfection of tanks and lakes. 2) Drying - Moisture is essential for growth of bacteria. ’āśDrying in air has dangerous effect on many bacteria. ’āśHowever, spores are unaffected. ’āśTherefore, it is not satisfactory method for sterilization. 1/18/2019 7

- 8. 3) Heat sterilization- it has also two type A)Dry heat sterilization- In dry heat sterilization, dry heat is used for sterilizing different materials. Heated air or fire is used in this process. As compared to the moist heat sterilization, the temperature is higher. The temp. is maintained for almost an hour to kill the most difficult of the resistant spores. Dry heat sterilization also have 4 type:- 1) Hot air oven 2) Red hot sterilization 3) Flaming 4) incineration 1/18/2019 8

- 9. 1) Hot air oven:- Hot air ovens are electrical devices which use dry heat to sterilize. They were originally developed by pasteur. ’āś Generally, they can be operated from 50 to 300 ┬░C, using a thermostat to control the temperature. ... An air circulating fan helps in uniform distribution of the heat. 2) Red hot sterilization:- Sterilization by holding them in Bunsen flame till they become red hot. It use for bacteriological loops, straight wires, tips of forceps & spatulas 1/18/2019 9

- 10. 3) Flaming:- This is a method of passing article over a flame, but not heating it to redness. Use- scalpels, mouth of test tubes, flask, glass slide & coverslips 4) Incineration:- Incineration is a waste treatment process that involves of organic substances contained in waste materials. ’āś This method also burns any organism to ash. It is used to sterilize medical and other biohazardous waste before it is discarded with non-hazardous waste 1/18/2019 10

- 11. B) Moist heat sterilization :- Moist heat method is used for heat sensitive materials and materials through which steam is permeable. culture media is also sterilized through moist heat sterilization. It has also 3 types:- 1) Below 100┬░C 2) Above 100┬░C 2) At 100┬░C 1) Below 100┬░C:- It has also 2 types i) Pasteurization- Its purpose is to reduce the bacterial population of a liquid such as a milk & destroy Organism that ma cause spoilage. Spores are not affected by this method. 1/18/2019 11

- 12. ii) inspissation:- Heating at 80-85┬░C for half an hour daily on three consecutive days. Serum or egg media are sterilized. 2) At 100┬░c:- It has also 2 types. i) Boiling:-Boiling is a very simple method of water disinfection. Heating water to a high temperature, 100┬░C, kills most of the pathogenic organisms, particularly viruses and bacteria causing waterborne diseases. In order for boiling to be most effective, the water must boil for at least 20 minutes. 1/18/2019 12

- 13. ii) Tyndallization:- Exposure at 100┬░C for 20-45 minutes for 3 successive days. Used for sterilizing sugars, gelatin, & serum containing media. 3) Above 100┬░C:- Autoclave ’āś Autoclaving is the most reliable method for sterilization. ’āśAutoclave use pressurized steam to destroy microorganism, and are the most dependable system available for the decontamination of laboratory waste & the sterilization of glass wares, media, & reagents. 1/18/2019 13

- 14. ’āśFor efficient heat transfer, steam must flush the air out of the autoclave chamber. ’āśGenerally the conditions employed are temperature up to 121-134┬░ for 15-20 minutes under 15 lbs pressure. The condition based on the type of the material used for sterilization. 1/18/2019 14

- 15. 4) Radiation sterilization:- It has 2 types. A) Non-ionizing(Hot sterilization):- i) Infrared rays- used for rapid mass sterilization of prepacked items such as syringe, catheters( a thin tube that is put into the body in order to remove liquids) ii) U.v. rays- used for disinfecting enclosed area such as entry ways, operation theatres & labs. 1/18/2019 15

- 16. B) Ionizing(Cold sterilization):- i) Gamma rays & X-rays:- Used for sterilizing plastics, syringes, swabs, animal feeds, oils, greases, fabric & metal foils ’ü▒ Advantages of radiation sterilization:- clean & dry process, ensure full exposure of object from all direction. ’ü▒Disadvantages:- posses threat to human, lengthy process, requires very qualified person 1/18/2019 16

- 17. Chemical methods 1) Gaseous sterilization:- i) Ethylene oxide ii) Formaldehyde gas 2) Liquid sterilization:- i) Alcohol ii) Phenol 1/18/2019 17

- 18. 1) Gaseous sterilization i. Ethylene oxide:- EtO sterilization is mainly use to sterilize medical & pharmaceutical products that can not support conventional high temperature steam sterilization- such as devices that incorporate electronic components, plastic packaging or plastic container. ’āś This method uses automatic device filled with ethylene oxide gas at temperature below 100┬░C to sterilize complex & delicate material. ’āś EtO destroys microorganism by chemically reacting with nucleic acid. 1/18/2019 18

- 19. ’ü▒ Advantages :- Fully automatic, high efficiency, 100% result ’ü▒Disadvantages:- Complex and time consuming process, carcinogenic safety concern ii. Formaldehyde gas:- Another low temperature method for sterilizing heat sensitive items is formaldehyde sterilization. Formaldehyde is an organic chemical compound which is a by-product of the metabolism of many organisms and is commonly found in fresh air, rainwater, foods, industrial products and fabrics. ’āśIt is considered even more dangerous than EtO and is therefore less commonly used for sterilization. 1/18/2019 19

- 20. ’āśFormaldehyde sterilization is used where sterilization by steam or high temperature is not possible ’āśFormaldehyde is soluble in water and its inactivation power is greatly improved by the presence of humidity. It is most commonly used as a disinfectant, but sometimes formaldehyde is used as a sterilizing agent. The process is known as low temperature steam and formaldehyde (LTSF) ’āśIn countries such as united kingdom, germany, sweden, denmark and norway sterilization by LSTF is accepted, but not common. On the other hand in several countries formaldehyde as a sterilizing agent is discouraged. LTSF has not been FDA cleared for use in healthcare facilities in the USA. 1/18/2019 20

- 21. ’ü▒Advantages:- Very reactive molecule, Faster cycle time compared to EtO, cost per cycle is lower than EtO, after sterilization most loads are available for immediate use ’ü▒Disadvantages:- The vapour is extremely irritating to the eyes, weak penetrating power compared to EtO, operates on a higher temperature than EtO, formaldehyde residue can remain on the sterilized goods if the rinsing phase is not 100% efficient. This can be harmful for the patients 1/18/2019 21

- 22. 2) Liquid sterilization i) Alcohol:- Alcohols are effective disinfectants for many reasons. They evaporate quickly, without leaving a residue. They are capable of dissolving lipids, which makes them effective against lipid-wrapped viral cells such as HIV and hepatitis A. They are inexpensive and relatively easy to handle, although their vapors are flammable. ’āśEthanol and isopropyl alcohol are both members of the alcohol family and have similar disinfectant properties. Ethanol is the type of alcohol present in alcoholic beverages. Isopropyl alcohol is also known as isopropanol, 2-propanol or rubbing alcohol. When used as disinfectants, both are typically at a concentration of 70 percent in water. 1/18/2019 22

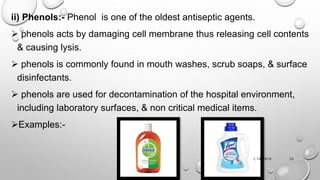

- 23. ii) Phenols:- Phenol is one of the oldest antiseptic agents. ’āś phenols acts by damaging cell membrane thus releasing cell contents & causing lysis. ’āś phenols is commonly found in mouth washes, scrub soaps, & surface disinfectants. ’āś phenols are used for decontamination of the hospital environment, including laboratory surfaces, & non critical medical items. ’āśExamples:- 1/18/2019 23

- 24. Filtration (Mechanical) methods ’āśFiltration sterilization used for heat sensitive materials to sterilize. ’āśFiltration process does not destroy but removes the microorganisms. ’āśFiltration allows for the exclusion of organisms based upon size. ’ü▒ Procedure:- The solution to be sterilized is passed through the filter and collected in the sterile receiver by the application of positive pressure to the nonsterile compartment or negative pressure to the sterile slide. 1/18/2019 24

- 25. Mode of action The filters are thought to function by one or usually a combination of the following: 1. Sieving or screening 2. Entrapment 3. Electrostatic attraction ’āś When a particle is larger than the pore size of the filter the particle is retained on the filter- this known as sieving or screening 1/18/2019 25

- 26. ’āśEntrapment occurs when a particle smaller than the size of the pore enters into the pore channel and lodges onto the curves of the channel while passing through it. ’āśIn Electrostatic attraction Particles are attracted & absorbed at the surface of the filter bed which is oppositely charged. ’āśThere are 4 types of filters:- 1. Membrane filters 2. Sintered or Fritted glass filters 3. Seitz filters 4. Ceramic filters 1/18/2019 26

- 27. 1) Membrane filters:- They are made of cellulose-derivative (acetate or nitrate). They are very fine. They are fixed in some suitable holders. ’āś Nominal pore size is 0.22 ┬▒ 0.02mm or less is required. ’āś The membranes are brittle when dry. In this condition they can be stored for years together. They become very tough when dipped in water. ’āś They are suitable for sterilizing aqueous and oily solutions but not for organic solvents such as alcohol, chloroform etc. 1/18/2019 27

- 28. ’āś They are sterilized by autoclaving or by ethylene oxide gas. They can not be sterilized by dry heat as they decompose above 130┬░C. ’āś Membrane filters are generally blocked by dirt particles and organisms. Pre-filtration (through glass-fibre paper prefilter) reduces the risks of membrane filter. ’āśExamples:- i) MF-Milipore - it is a mixture of cellulose esters ii) Sartorius regular ŌĆō it is made of cellulose nitrate 1/18/2019 28

- 29. 1/18/2019 29

- 30. 2) Sintered (or Fritted) glass filters:- ’āś Borosilicate glass is finely powdered in a ball-mill and the particles of required size are separated. ’āś This is packed into disc mounted and heated till the particles get fused. The disc thus made have pore size of 2 mm and are used for filtration. ’āś They are cleaned with the help of sulfuric acid. 1/18/2019 30

- 31. 3) Seitz filters:- ’āś It consists of two parts. ’āś Lower part filled with a perforated plate over which compressed asbestos pad is placed. ’āś Upper part has a valve through which pressure can be applied. ’āś Both parts joined together by winged nuts. ’āś The main advantage of this filter is that no risk of contamination & easy to use. ’āś For viscous solution they are more suitable. 1/18/2019 31

- 32. 4) Ceramic filters:- ’āś Ceramic water filters are an inexpensive and effective type of water filter, that rely on the small pore size of ceramic material to filter dirt, debris, and bacteria out. ’āś However, filters are typically not effective against viruses since they are small enough to pass through to the "clean" side of the filter. ’āś Ceramic filtration does not remove chemical contaminants. ’āś However, some manufacturers (especially of ceramic candle filters) incorporate a high-performance activated carbon core inside the ceramic filter that reduces organic and metallic contaminants.1/18/2019 32

- 33. ’āś The two most common types of ceramic water filter are pot-type and candle-type filters. 1/18/2019 33

- 34. ’üČ REFRENCES:- ’āś Principle and practice of disinfection and sterilization by A P Fraise ’āś Wikipedia ’āś www.study.com 1/18/2019 34

- 35. 1/18/2019 35