STIl-Audit report

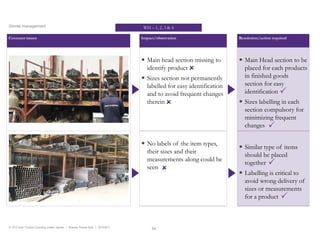

- 1. ÂĐ 2013 Grant Thornton Consulting Limited, Uganda | Business Process Audit | 30/10/2013 Stores management Covenant issues Impact/observation Resolution/action required ï Main head section missing to identify product ï Sizes section not permanently labelled for easy identification and to avoid frequent changes therein ï Main Head section to be placed for each products in finished goods section for easy identification ï Sizes labelling in each section compulsory for minimizing frequent changes ï No labels of the item types, their sizes and their measurements along could be seen ï Similar type of items should be placed together ï Labelling is critical to avoid wrong delivery of sizes or measurements for a product ïŧ ï WH â 1, 2, 3 & 4 ïŧ ï ïŧ ï ï 54

- 2. ÂĐ 2013 Grant Thornton Consulting Limited, Uganda | Business Process Audit | 30/10/2013 Stores management Covenant issues Impact/observation Resolution/action required ï Damaged items are kept with finished or semi finished products ï Damaged items considered for scrap or reuse or re production should be stated and classified ï Finished goods produced are damaged due to non- identified rack and new produced items are stacked above the previous produced items ï Such damaged items are a huge loss to company and therefore needs to be avoided for better stock management ïŧ ï WH â 1, 2, 3 & 4 ïŧ ï 55

- 3. ÂĐ 2013 Grant Thornton Consulting Limited, Uganda | Business Process Audit | 30/10/2013 Stores management Covenant issues Impact/observation Resolution/action required ï Raw materials section not tagged ï No arrangement and alignment of goods in order ï Similar items at different warehouse locations is a serious issue for accuracy of goods identifying the goods issued for production ï Rolls are open and in damaged which may or may not be recorded in SAP (damaged or WIP) which again shall not give a true and fair view of actual raw mateirals ï Tagging section as raw material/finished goods is critical and important ï At one location all the materials should be arranged and stacked in LIFO or FIFO basis ï If possible STIL should segregate duties of raw- material keeper also monitoring for damaged or goods in production (WIP) status and duties of finished ï WH â 1, 2, 3 & 4 56

- 4. ÂĐ 2013 Grant Thornton Consulting Limited, Uganda | Business Process Audit | 30/10/2013 Stores management Covenant issues Impact/observation Resolution/action required ï Scrap goods or finished goods cannot be measured for the attached view in the store ï Sections showing many different sizes of items as well as different products ï Items to kept in proper rack or section area to be easily identified ï Walking area to be clean to avoid any mishap or incidences causing human accident ï WH â 1, 2, 3 & 4 ï 57

- 5. ÂĐ 2013 Grant Thornton Consulting Limited, Uganda | Business Process Audit | 30/10/2013 Stores management Covenant issues Impact/observation Resolution/action required ï Tags are attached to the finished goods, however it can be seen that some items can be removed and the tags are not clearly indefinable for a product ï Damaged items considered for scrap or reuse or re production should be stated and classified ï Physical stock take is done on different color combination basis which changes every time the physical stock take is made ï Color codes for categories to be defined ï FIFO or LIFO to be used for easy stock count and easy management ï WH â 1, 2, 3 & 4 ï 58

- 6. ÂĐ 2013 Grant Thornton Consulting Limited, Uganda | Business Process Audit | 30/10/2013 Stores management Covenant issues Impact/observation Resolution/action required ï Special order or standard order is not separated and chances of human error are high ï To improve customer service, separate sections to load special customer orders or standard orders is highly recommended ï Different sizes and variants stacked together and also at multiple warehouse locations ï Similar items to be stacked together ï WH â 1, 2, 3 & 4 ï 59