Use of Flow Simulation in designing a Suction Pump

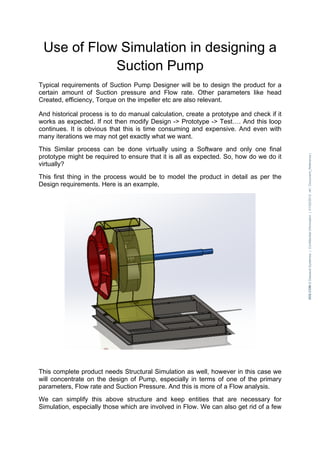

- 1. Use of Flow Simulation in designing a Suction Pump Typical requirements of Suction Pump Designer will be to design the product for a certain amount of Suction pressure and Flow rate. Other parameters like head Created, efficiency, Torque on the impeller etc are also relevant. And historical process is to do manual calculation, create a prototype and check if it works as expected. If not then modify Design -> Prototype -> Test…. And this loop continues. It is obvious that this is time consuming and expensive. And even with many iterations we may not get exactly what we want. This Similar process can be done virtually using a Software and only one final prototype might be required to ensure that it is all as expected. So, how do we do it virtually? This first thing in the process would be to model the product in detail as per the Design requirements. Here is an example, This complete product needs Structural Simulation as well, however in this case we will concentrate on the design of Pump, especially in terms of one of the primary parameters, Flow rate and Suction Pressure. And this is more of a Flow analysis. We can simplify this above structure and keep entities that are necessary for Simulation, especially those which are involved in Flow. We can also get rid of a few 3DS.COM©DassaultSystèmes|ConfidentialInformation|01/02/2012ref.:Document_Reference|

- 2. 2 3DS.COM©DassaultSystèmes|ConfidentialInformation|01/02/2012ref.:Document_Reference| entities which can help in simplifying the setup without harming the Flow region. Normally, Bolt holes, Bolts, keyways etc can be suppressed. There is also a need to add a few extra pipes at the inlet and outlet to help stabilize the flow for calculation purpose. We also need a closed entity for Flow Simulation and that is achieved by creating lids to these extended end pipes. The CAD model is now ready for Simulation. The below model shows a refined and ready model for analysis. Now let’s start with Simulation, the steps would include:- 1) Create the initial settings. 2) Representation of the rotating region. 3) Applying the boundary conditions. 4) Results interpretation. 1) Create the initial settings, In SolidWorks Go to Flow Simulation-> Wizard, Follow the steps through it, it gives options to select the Fluid, activate necessary options like Rotating region, we can set the units etc….

- 3. 3 3DS.COM©DassaultSystèmes|ConfidentialInformation|01/02/2012ref.:Document_Reference| 2) Representation of the rotating region, see the below image, we have to create a component that is encompassing the rotating component and to be specific the Impeller blades Flow Simulation uses this rotating component to Simulate the rotating effect. It is a simulation where in the Blades are static and the fluid around it is considered to be rotating. It is a kind of relative motion. And because of blades the effect of impeller is created. This component is used for applying the rotating region boundary condition only and it is actually suppressed There on we applying the Rotating region boundary condition to this dummy component, the option is present under Flow Simulation-> Insert ->Rotating Region, see the below image

- 4. 4 3DS.COM©DassaultSystèmes|ConfidentialInformation|01/02/2012ref.:Document_Reference| 3) Applying the Boundary Conditions Both the inlet and outlet are set at atmospheric pressure, the can be done by Right Mouse button clicking on the Boundary conditions option and select the inner surfaces of the lids.

- 5. 5 3DS.COM©DassaultSystèmes|ConfidentialInformation|01/02/2012ref.:Document_Reference| That’s it the model is ready to be solved. The only other thing that one needs to consider is the quality of mesh and the important goals that one wants to ensure that convergence has happened. 4) Results interpretation: - I would like to delve a bit more on it as it needs careful attention. As discussed above in this case we will concentrate on Suction Pressure and Volume Flow rate or capacity of the Pump. a) Volume Flow Rate: - This can be observed at one of the inlet/outlets or any other location where the measurements are done. If results are compared with practical results be aware on how and where are they measured. Especially, if the fluid is compressible then we can see a variation in results across the flow. In this case we will see the Velocity at a cross section near the inlet of the Pump. See the image below, it can be seen that velocity changes across the cross section. Using Velocity and Cross Section area we can find the Volume flow rate. Capacity/Volume Flow rate = Velocity* Area. The value of velocity that we use in this equation is important. Software has options to calculate this value or we can take averaged values. The below image shows the Velocity plot. b) The next one is the Suction Pressure. We need to understand that if it is a discussion on Suction pressure then it will be a pressure below atmospheric pressures. This negative pressure will help in pulling the air or any other application where this pump will be used. We can get a Cut plot of the Pressure at appropriate location to understand on how this pressure varies.

- 6. 6 3DS.COM©DassaultSystèmes|ConfidentialInformation|01/02/2012ref.:Document_Reference| In Conclusion, we saw how we can simulate a Suction pump and understand the Suction Pressure/Volume Flow rate. Knowing this, if it is not as per the expected design parameters then we can do relevant design changes to get the expected values. The below video shows the process that has been discussed above. http://youtu.be/FUpYrgdQAhE