super air meter

0 likes633 views

- The Super Air Meter (SAM) is a new device that can quickly measure the quality of air voids in fresh concrete by determining a SAM number. - Testing of 95 concrete mixtures found that a SAM number below 0.2 correlates with adequate freeze-thaw durability as measured by ASTM standards. - The SAM test takes about 10 minutes to perform and provides a consistent measure of air content and void quality compared to traditional hardened air void analysis, making it suitable for field use.

1 of 40

Downloaded 12 times

Recommended

Modular Construction In India : Opportunities and challenges pdf notes

Modular Construction In India : Opportunities and challenges pdf notesFluidconstructions

Ėý

The "Modular Construction in India: Opportunities and Challenges" PDF notes offer an insightful exploration of a burgeoning trend in the construction industry. The document delves into the concept of modular construction and its potential applications within the Indian context. It examines the opportunities presented by modular construction methods, such as increased efficiency, cost-effectiveness, and sustainability. Additionally, the notes address the unique challenges that may arise in implementing modular construction practices in India, including regulatory hurdles, cultural considerations, and infrastructure limitations. Through a combination of case studies, analysis, and expert insights, the document provides readers with a comprehensive understanding of the opportunities and challenges associated with modular construction in India. It serves as a valuable resource for industry professionals, policymakers, and stakeholders seeking to capitalize on the benefits of this innovative approach to building construction.Chapter 1-types of structures and loads

Chapter 1-types of structures and loadsISET NABEUL

Ėý

The document discusses different types of structures, structural elements, and loads that act on structures. It defines structures as systems used to support loads like buildings and bridges. It describes structural analysis as predicting a structure's performance under prescribed loads. The main types of loads discussed are: dead loads from structural elements/attachments; live loads from occupancy/use; wind loads from pressure; snow loads; and earthquake loads from ground shaking. Load combinations are presented from codes like ASCE and IBC to safely design structures for all foreseeable load scenarios.CON 122 Session 3 - Air-Entraining Admixtures

CON 122 Session 3 - Air-Entraining Admixturesalpenaccedu

Ėý

The document discusses air entraining admixtures, which generate tiny stable bubbles in concrete to protect against freezing and thawing cycles by providing spaces for expanding water to enter and exit without damaging the concrete; it describes how air entrainment improves durability in freeze-thaw and deicer exposed environments and explains the mechanism by which air voids in concrete provide this protection against frost damage and scaling.Durability of Concrete

Durability of Concrete er_kamal

Ėý

Durability is the ability of concrete to resist weathering actions, chemical attacks, and abrasion while maintaining its desired engineering properties. A durable concrete structure withstands deterioration over its design life through exposure to the environment. Factors that influence durability include the water-cement ratio, cement content, cover thickness, type of aggregates used, and curing of the concrete. Permeability is an important indicator of durability, with lower permeability reducing susceptibility to chemical attacks. Proper compaction and curing help reduce the permeability of concrete.Durabilty of concrete

Durabilty of concretevairamuni3

Ėý

Concrete durability is affected by many factors including the quality of materials used, water-cement ratio, compaction, and curing. Lack of durability can result in cracking, scaling, spalling, or disintegration of concrete. Environmental factors like abrasion, biological growth, freezing and thawing, or chemical attacks from carbonation, chlorides, acids, or sulfates can also damage concrete over time if not properly addressed. Proper concrete mix design, placement, and curing can improve durability.Quality control of concrete

Quality control of concreteGaurang Kakadiya

Ėý

This document discusses quality control in concrete construction. It explains that concrete is made by mixing cement, fine aggregate, coarse aggregate, water, and admixtures. Quality control is important to ensure the concrete has strength, durability, and aesthetics. Quality control involves testing the materials used, the fresh concrete mix, and the hardened concrete. Tests on fresh concrete include slump and compacting factor tests, while tests on hardened concrete include compression, tensile, and flexural strength tests. The document outlines the quality control process from the production of materials to placement and curing of the concrete.Concrete Corrosion of Reinforcing Steel

Concrete Corrosion of Reinforcing SteelSteven E. Kreeley, EIT

Ėý

The document discusses corrosion of steel reinforcement in concrete and methods to minimize it. It describes how carbonation and chloride attacks can cause corrosion through electrochemical processes. Various techniques are presented to mitigate corrosion, including using epoxy coatings on rebar, adding fibers or memory alloys to concrete, using admixtures, hybrid fiber reinforced concrete, and fiber reinforced polymers applied after corrosion begins. Ongoing research gaps and a proposed future study are also mentioned.Durability of concrete

Durability of concreteShan Joy

Ėý

The document discusses the durability of concrete and the factors that affect it. It defines durability as the ability of concrete to resist weathering, chemical attack, and abrasion while maintaining its desired properties. The main factors discussed are abrasion, biological factors, temperature effects, freezing and thawing, and various types of chemical attacks including carbonation, chloride attack, acid attack, and sulfate attack. Prevention and mitigation methods are provided for each factor.Case study on non destructive testing on concrete structures

Case study on non destructive testing on concrete structuresLahmeyer International, UAE

Ėý

The document discusses non-destructive testing methods for concrete structures. It describes various NDT techniques like ultrasonic pulse velocity testing, rebound hammer testing, and half-cell potential testing. Three case studies on different structures are presented where these tests were used to evaluate concrete quality and integrity. The case studies found the concrete quality to vary from good to excellent. Non-destructive testing can check concrete structures without damage and help assess strength, cracks, reinforcement condition, and more. Recent Advances in Concrete Technology

Recent Advances in Concrete TechnologyCochin University

Ėý

The document discusses lightweight concrete, including its production, properties, and applications. Lightweight concrete has a density ranging from 300kg/m3 to 1850kg/m3, which is achieved through the inclusion of air into its composition. This can be done by replacing normal aggregate with hollow, cellular, or porous aggregate that contains voids. Lightweight concrete offers benefits like reduced self-weight, increased productivity, better thermal insulation, seismic resistance, and fire protection compared to normal concrete. It can be classified based on its intended use, such as structural, non-load bearing walls, or insulation purposes.Durability of concrete

Durability of concreteRajesh Prasad

Ėý

This document discusses quality control and durability factors in concrete. It defines quality as conformance to requirements and durability as a concrete's ability to resist deterioration when exposed to the environment. Several factors influence concrete durability, including the materials used, water-cement ratio, compaction, curing and the physical and chemical conditions of the service environment. Common durability issues include corrosion, cracking from sulfate attack or alkali-silica reaction, and carbonation reducing alkalinity. Proper quality control of materials and construction processes is needed to produce durable concrete.Quality control of concrete

Quality control of concreteGaurang Kakadiya

Ėý

This document discusses quality control of concrete through various tests on fresh and hardened concrete. It begins with an introduction to concrete and quality, then discusses where quality control begins in the production of materials and continues through handling, batching, mixing, transporting and placing concrete. Key tests on fresh concrete include slump and compacting factor tests, while tests on hardened concrete include compression, tensile strength, and flexural strength tests to evaluate the quality and strength of the concrete. The document also reviews materials used in concrete such as cement, water, aggregates, and admixtures.Cracks in Buildings

Cracks in BuildingsAravind Samala

Ėý

The document discusses cracks in buildings, including the types, causes, effects, and methods for repairing cracks. It identifies two main types of cracks: structural cracks that could endanger safety, and non-structural cracks caused by factors like moisture, temperature changes, or chemical reactions. Left unaddressed, cracks can accelerate concrete deterioration and carbonation, compromise waterproofing, and affect building appearance and durability. The document outlines various techniques for repairing cracks, such as epoxy injection, routing and sealing, stitching, drilling and plugging, and gravity filling. It emphasizes the importance of both preventing cracks and properly repairing existing cracks to maintain building integrity.Quality Control

Quality ControlCarul Push

Ėý

This document discusses quality control procedures for evaluating a project. It outlines several ways to assess quality, including submitting progress reports, conducting pre-and post-tests, providing a warranty, and acknowledging limitations. Quality control focuses on controlling elements of production, ensuring competence, and addressing soft elements like culture. It emphasizes testing products for defects and reporting issues to management.Repairs and rehabilitation 2012

Repairs and rehabilitation 2012Dhaval Jadhav

Ėý

The document provides guidelines for repair and rehabilitation of existing reinforced concrete buildings. It discusses causes of concrete deterioration like permeability, aggressive agents, and condition surveys. Non-destructive tests are recommended to evaluate concrete quality, cracking, and corrosion. The approach involves identifying deterioration causes, assessing damage extent, and selecting appropriate repair materials and methods to rehabilitate structures in a systematic and cost-effective manner.Presentation on non destructive testing

Presentation on non destructive testingMd. Shahin Manjurul Alam

Ėý

Non-destructive testing (NDT) refers to techniques used to evaluate the properties of a material, component, or structure without damaging it. The document discusses several common NDT methods, including visual testing, dye penetrant testing, magnetic particle testing, ultrasonic testing, eddy current testing, and radiography testing. It provides details on the basic principles, processes, advantages, and limitations of these important NDT techniques.corrosion and protection of steel reinforced c...

corrosion and protection of steel reinforced c...Emad Behdad

Ėý

Corrosion of steel reinforcement in concrete is an electrochemical process that occurs when oxygen, water and chlorides penetrate the concrete and reach the steel. It results in rust formation which expands and cracks the concrete. Chlorides from deicing salts or seawater and carbonation are the primary causes of corrosion. Methods to prevent corrosion include using epoxy-coated rebar, thermally sprayed zinc or aluminum coatings, fly ash concrete, cathodic protection systems, and corrosion inhibitors. Titanium mesh anodes can provide cathodic protection without needing power sources.Non destructive test on concrete (ndt)

Non destructive test on concrete (ndt)Abhishek Gupta

Ėý

NDT techniques can evaluate concrete structures in a non-destructive manner by assessing strength, quality, and durability without damaging the concrete. Some key NDT tests described in the document include rebound hammer testing to estimate concrete strength, UPV testing to evaluate homogeneity and detect cracks or voids, half-cell potential testing to assess corrosion risk, and cover meter testing to determine reinforcement location and concrete cover thickness. NDT allows for more extensive evaluation than destructive testing methods at a lower cost. Test results are influenced by factors like moisture, temperature, reinforcement properties, and concrete composition.poster_presentation_Rev 23

poster_presentation_Rev 23Joel Albin

Ėý

- The document discusses the design of two sampling systems for a breathalyzer: a piston/cylinder system and a bellows system. The piston/cylinder system has better repeatability but is more difficult to assemble, while the bellows system is easier to assemble but has issues at high and low temperatures.

- Testing showed the piston/cylinder system had volume repeatability within 1% while the bellows system was cheaper at $3 less but had difficulties at temperature extremes.

- The goal was to improve the reliability and performance of an existing breathalyzer to allow entering new markets with requirements such as sampling volume repeatability within 1 mL.Quality install testing procedures for forced air systems

Quality install testing procedures for forced air systemsCenter for Energy and Environment

Ėý

This document discusses procedures for testing forced air HVAC systems to ensure quality installation and optimal performance. Key tests described are measuring total external static pressure (TESP) and air flow in cubic feet per minute (CFM). High or unbalanced static pressure can reduce efficiency and comfort, while insufficient air flow impacts humidity control, indoor air quality, and system function. The document provides examples of how to measure TESP and CFM using tools like manometers, static probes, and hot wire anemometers. Identifying issues like restrictive filters or ductwork through testing can lead to solutions that improve a system's efficiency and owner's experience.Ventilation Options

Ventilation OptionsBrett Dillon

Ėý

Ventilation Options were discussed including purposes, methods, controls, standards, and calculations. Residential ventilation is needed for moisture control, odor control, and pollution dilution. Methods include intermittent source control, whole house, supply only, exhaust only, and balanced. Controls can include no controls, timer controls, humidity controls, and temperature controls. Standards discussed were ASHRAE 62.2 and Building Science Corp. Standard 01-2013. Ventilation rates are calculated based on conditioned floor area and number of bedrooms. Intermittent ventilation requires determining required airflow, fractional on-time, and effectiveness. Modeling ventilation correctly in software is important for HERS ratings.04 tests

04 testsInstituto del cemento y HormigÃģn de Chile

Ėý

Seminario Internacional de Buenas PrÃĄcticas y Mejoramiento del DesempeÃąo de Hormigones para Pavimentos04 tests

04 testsInstituto del cemento y HormigÃģn de Chile

Ėý

Seminario Internacional:

DosificaciÃģn y especificaciÃģn de hormigÃģn por desempeÃąo

"Buenas PrÃĄcticas y Mejoramiento del DesempeÃąo de Hormigones para Pavimentos"Lab 3 CE 3700

Lab 3 CE 3700Chase Bowman

Ėý

Group 3 performed a test to determine the compressive strength of cement mortar cubes with different water-to-cement ratios. They mixed mortar with a 0.4 ratio and formed 3 cubes. After curing for 7 days, the cubes were tested. The average compressive strength was 6,283 PSI, slightly lower than expected likely due to improper tamping technique introducing air bubbles. Compared to other groups' cubes, the 0.4 ratio cubes did not show as high strength as predicted. Estimates for 14 and 28-day strengths were also calculated using standard equations.Steam Reformer Surveys - Techniques for Optimization of Primary Reformer Oper...

Steam Reformer Surveys - Techniques for Optimization of Primary Reformer Oper...Gerard B. Hawkins

Ėý

Introduction

Background Radiation and Temperature Measurement

Reformer Survey Inputs

Other Troubleshooting Tools

Safety

Preparation

Onsite Data Collection

TWT Survey

Observation/Troubleshooting

Modelling and Analysis

Results/Outputs

Case Studies

Conclusions

Case Study 1

Case Study 2

Case Study 3

Conclusions

USP 797/800 Cleanroom Compliance by Terra Universal

USP 797/800 Cleanroom Compliance by Terra UniversalTerra Universal

Ėý

Understand the scope and compliance costs of the most recent CGMP standards and USP

guidelines for cleanroom design and operation! Webinar topics covered by our industry-expert speakers include DQSA compliance, designing for USP 800 hazardous drug compounding, and cleanroom cost estimating. Industry experts Will summarize the revised regulations and what theymean for pharmacy cleanrooms. Registrants Will receive Terra Universal's white paper "Designing your compounding Cleanroom for USP/cGMP Compliance."

Speakers

Dr. Chris Munoz, PharmD and Principle Consultant at ITL Consulting

and teaches pharmacy compounding at the University of Southern California (USC)

School of Pharmacy, and serves on the California Pharmacists Association's Policy Committee and Board of Directors. Following Chris's earlier work in compounding pharmacies and for pharmaceutical companies, he began a consulting ïŽrm specializing in the business of, and regulatory affairs for, pharmacy compounding.

Dr. Jesse Martinez, PharmD, FASCP and Vice Dean of the College of Pharmacy,

Western University of Heath Sciences

Dr. Jesse Martinez has 37 years Of experience in compounding, sterile and non-sterile pharmacy operations and administration, and research. He has served on local, state and national pharmacy associations and currently teaches fourth-year pharmacy students in advanced Classes that include pharmacist-in-charge training. Jesse consults for the pharmacy industry and is a recognized expert in USP 795, 797 and 300 compliance.

For More Information Please visit

http://www.terrauniversal.com/public/webinar-information-and-downloads.php

http://www.terrauniversal.com/cleanrooms/modular-clean-rooms-x.phpMCE 2016 - S. Filippini - LUVE

MCE 2016 - S. Filippini - LUVECentro Studi Galileo

Ėý

LU-VE has experience producing heat exchangers for refrigeration and HVAC, especially with natural refrigerants like CO2. They presented on CO2 heat exchangers and their work on the NXTHPG project. Their CO2 test facility in Europe allows them to test heat exchangers under stationary conditions. Software predictions of capacity and pressure drop generally match test results well within 10%. Testing of CO2 evaporators showed capacity increases with Reynolds number as expected. Their 5mm tube CO2 coil for the NXTHPG project was smaller and lighter than the standard design while maintaining performance. CFD analysis helped optimize the fan configuration to increase COP by 2%.Project 1 ME 4J03

Project 1 ME 4J03Shaun Chiasson

Ėý

This document summarizes a mechanical engineering student's project analyzing mixing of hot and cold air flows in a duct. The student performed an energy balance to determine if mixing the flows to 200°C was feasible. Grid independence studies and numerous design attempts were made before achieving a final design that almost met criteria, with exit temperature within 12°C of the goal and pressure drop 34Pa over the limit. The challenges around recirculation and difficulty meeting the strict limitations were also discussed.Energy Savings from Air Sealing Large Buildings

Energy Savings from Air Sealing Large BuildingsCenter for Energy and Environment

Ėý

The document summarizes research on air sealing commercial buildings to reduce energy use. It discusses methods for measuring air leakage, findings from whole-building air leakage tests of 387 commercial buildings in the US, and a study on air sealing 7 Minnesota buildings. On average, US buildings leak 0.72 cfm/ft2 but tighter construction (<0.25 cfm/ft2) can reduce infiltration by 70% and energy use by 5-20%. The Minnesota study found sealing reduced leakage in all 7 buildings to below the standard of 0.25 cfm/ft2.More Related Content

Viewers also liked (10)

Case study on non destructive testing on concrete structures

Case study on non destructive testing on concrete structuresLahmeyer International, UAE

Ėý

The document discusses non-destructive testing methods for concrete structures. It describes various NDT techniques like ultrasonic pulse velocity testing, rebound hammer testing, and half-cell potential testing. Three case studies on different structures are presented where these tests were used to evaluate concrete quality and integrity. The case studies found the concrete quality to vary from good to excellent. Non-destructive testing can check concrete structures without damage and help assess strength, cracks, reinforcement condition, and more. Recent Advances in Concrete Technology

Recent Advances in Concrete TechnologyCochin University

Ėý

The document discusses lightweight concrete, including its production, properties, and applications. Lightweight concrete has a density ranging from 300kg/m3 to 1850kg/m3, which is achieved through the inclusion of air into its composition. This can be done by replacing normal aggregate with hollow, cellular, or porous aggregate that contains voids. Lightweight concrete offers benefits like reduced self-weight, increased productivity, better thermal insulation, seismic resistance, and fire protection compared to normal concrete. It can be classified based on its intended use, such as structural, non-load bearing walls, or insulation purposes.Durability of concrete

Durability of concreteRajesh Prasad

Ėý

This document discusses quality control and durability factors in concrete. It defines quality as conformance to requirements and durability as a concrete's ability to resist deterioration when exposed to the environment. Several factors influence concrete durability, including the materials used, water-cement ratio, compaction, curing and the physical and chemical conditions of the service environment. Common durability issues include corrosion, cracking from sulfate attack or alkali-silica reaction, and carbonation reducing alkalinity. Proper quality control of materials and construction processes is needed to produce durable concrete.Quality control of concrete

Quality control of concreteGaurang Kakadiya

Ėý

This document discusses quality control of concrete through various tests on fresh and hardened concrete. It begins with an introduction to concrete and quality, then discusses where quality control begins in the production of materials and continues through handling, batching, mixing, transporting and placing concrete. Key tests on fresh concrete include slump and compacting factor tests, while tests on hardened concrete include compression, tensile strength, and flexural strength tests to evaluate the quality and strength of the concrete. The document also reviews materials used in concrete such as cement, water, aggregates, and admixtures.Cracks in Buildings

Cracks in BuildingsAravind Samala

Ėý

The document discusses cracks in buildings, including the types, causes, effects, and methods for repairing cracks. It identifies two main types of cracks: structural cracks that could endanger safety, and non-structural cracks caused by factors like moisture, temperature changes, or chemical reactions. Left unaddressed, cracks can accelerate concrete deterioration and carbonation, compromise waterproofing, and affect building appearance and durability. The document outlines various techniques for repairing cracks, such as epoxy injection, routing and sealing, stitching, drilling and plugging, and gravity filling. It emphasizes the importance of both preventing cracks and properly repairing existing cracks to maintain building integrity.Quality Control

Quality ControlCarul Push

Ėý

This document discusses quality control procedures for evaluating a project. It outlines several ways to assess quality, including submitting progress reports, conducting pre-and post-tests, providing a warranty, and acknowledging limitations. Quality control focuses on controlling elements of production, ensuring competence, and addressing soft elements like culture. It emphasizes testing products for defects and reporting issues to management.Repairs and rehabilitation 2012

Repairs and rehabilitation 2012Dhaval Jadhav

Ėý

The document provides guidelines for repair and rehabilitation of existing reinforced concrete buildings. It discusses causes of concrete deterioration like permeability, aggressive agents, and condition surveys. Non-destructive tests are recommended to evaluate concrete quality, cracking, and corrosion. The approach involves identifying deterioration causes, assessing damage extent, and selecting appropriate repair materials and methods to rehabilitate structures in a systematic and cost-effective manner.Presentation on non destructive testing

Presentation on non destructive testingMd. Shahin Manjurul Alam

Ėý

Non-destructive testing (NDT) refers to techniques used to evaluate the properties of a material, component, or structure without damaging it. The document discusses several common NDT methods, including visual testing, dye penetrant testing, magnetic particle testing, ultrasonic testing, eddy current testing, and radiography testing. It provides details on the basic principles, processes, advantages, and limitations of these important NDT techniques.corrosion and protection of steel reinforced c...

corrosion and protection of steel reinforced c...Emad Behdad

Ėý

Corrosion of steel reinforcement in concrete is an electrochemical process that occurs when oxygen, water and chlorides penetrate the concrete and reach the steel. It results in rust formation which expands and cracks the concrete. Chlorides from deicing salts or seawater and carbonation are the primary causes of corrosion. Methods to prevent corrosion include using epoxy-coated rebar, thermally sprayed zinc or aluminum coatings, fly ash concrete, cathodic protection systems, and corrosion inhibitors. Titanium mesh anodes can provide cathodic protection without needing power sources.Non destructive test on concrete (ndt)

Non destructive test on concrete (ndt)Abhishek Gupta

Ėý

NDT techniques can evaluate concrete structures in a non-destructive manner by assessing strength, quality, and durability without damaging the concrete. Some key NDT tests described in the document include rebound hammer testing to estimate concrete strength, UPV testing to evaluate homogeneity and detect cracks or voids, half-cell potential testing to assess corrosion risk, and cover meter testing to determine reinforcement location and concrete cover thickness. NDT allows for more extensive evaluation than destructive testing methods at a lower cost. Test results are influenced by factors like moisture, temperature, reinforcement properties, and concrete composition.Similar to super air meter (20)

poster_presentation_Rev 23

poster_presentation_Rev 23Joel Albin

Ėý

- The document discusses the design of two sampling systems for a breathalyzer: a piston/cylinder system and a bellows system. The piston/cylinder system has better repeatability but is more difficult to assemble, while the bellows system is easier to assemble but has issues at high and low temperatures.

- Testing showed the piston/cylinder system had volume repeatability within 1% while the bellows system was cheaper at $3 less but had difficulties at temperature extremes.

- The goal was to improve the reliability and performance of an existing breathalyzer to allow entering new markets with requirements such as sampling volume repeatability within 1 mL.Quality install testing procedures for forced air systems

Quality install testing procedures for forced air systemsCenter for Energy and Environment

Ėý

This document discusses procedures for testing forced air HVAC systems to ensure quality installation and optimal performance. Key tests described are measuring total external static pressure (TESP) and air flow in cubic feet per minute (CFM). High or unbalanced static pressure can reduce efficiency and comfort, while insufficient air flow impacts humidity control, indoor air quality, and system function. The document provides examples of how to measure TESP and CFM using tools like manometers, static probes, and hot wire anemometers. Identifying issues like restrictive filters or ductwork through testing can lead to solutions that improve a system's efficiency and owner's experience.Ventilation Options

Ventilation OptionsBrett Dillon

Ėý

Ventilation Options were discussed including purposes, methods, controls, standards, and calculations. Residential ventilation is needed for moisture control, odor control, and pollution dilution. Methods include intermittent source control, whole house, supply only, exhaust only, and balanced. Controls can include no controls, timer controls, humidity controls, and temperature controls. Standards discussed were ASHRAE 62.2 and Building Science Corp. Standard 01-2013. Ventilation rates are calculated based on conditioned floor area and number of bedrooms. Intermittent ventilation requires determining required airflow, fractional on-time, and effectiveness. Modeling ventilation correctly in software is important for HERS ratings.04 tests

04 testsInstituto del cemento y HormigÃģn de Chile

Ėý

Seminario Internacional de Buenas PrÃĄcticas y Mejoramiento del DesempeÃąo de Hormigones para Pavimentos04 tests

04 testsInstituto del cemento y HormigÃģn de Chile

Ėý

Seminario Internacional:

DosificaciÃģn y especificaciÃģn de hormigÃģn por desempeÃąo

"Buenas PrÃĄcticas y Mejoramiento del DesempeÃąo de Hormigones para Pavimentos"Lab 3 CE 3700

Lab 3 CE 3700Chase Bowman

Ėý

Group 3 performed a test to determine the compressive strength of cement mortar cubes with different water-to-cement ratios. They mixed mortar with a 0.4 ratio and formed 3 cubes. After curing for 7 days, the cubes were tested. The average compressive strength was 6,283 PSI, slightly lower than expected likely due to improper tamping technique introducing air bubbles. Compared to other groups' cubes, the 0.4 ratio cubes did not show as high strength as predicted. Estimates for 14 and 28-day strengths were also calculated using standard equations.Steam Reformer Surveys - Techniques for Optimization of Primary Reformer Oper...

Steam Reformer Surveys - Techniques for Optimization of Primary Reformer Oper...Gerard B. Hawkins

Ėý

Introduction

Background Radiation and Temperature Measurement

Reformer Survey Inputs

Other Troubleshooting Tools

Safety

Preparation

Onsite Data Collection

TWT Survey

Observation/Troubleshooting

Modelling and Analysis

Results/Outputs

Case Studies

Conclusions

Case Study 1

Case Study 2

Case Study 3

Conclusions

USP 797/800 Cleanroom Compliance by Terra Universal

USP 797/800 Cleanroom Compliance by Terra UniversalTerra Universal

Ėý

Understand the scope and compliance costs of the most recent CGMP standards and USP

guidelines for cleanroom design and operation! Webinar topics covered by our industry-expert speakers include DQSA compliance, designing for USP 800 hazardous drug compounding, and cleanroom cost estimating. Industry experts Will summarize the revised regulations and what theymean for pharmacy cleanrooms. Registrants Will receive Terra Universal's white paper "Designing your compounding Cleanroom for USP/cGMP Compliance."

Speakers

Dr. Chris Munoz, PharmD and Principle Consultant at ITL Consulting

and teaches pharmacy compounding at the University of Southern California (USC)

School of Pharmacy, and serves on the California Pharmacists Association's Policy Committee and Board of Directors. Following Chris's earlier work in compounding pharmacies and for pharmaceutical companies, he began a consulting ïŽrm specializing in the business of, and regulatory affairs for, pharmacy compounding.

Dr. Jesse Martinez, PharmD, FASCP and Vice Dean of the College of Pharmacy,

Western University of Heath Sciences

Dr. Jesse Martinez has 37 years Of experience in compounding, sterile and non-sterile pharmacy operations and administration, and research. He has served on local, state and national pharmacy associations and currently teaches fourth-year pharmacy students in advanced Classes that include pharmacist-in-charge training. Jesse consults for the pharmacy industry and is a recognized expert in USP 795, 797 and 300 compliance.

For More Information Please visit

http://www.terrauniversal.com/public/webinar-information-and-downloads.php

http://www.terrauniversal.com/cleanrooms/modular-clean-rooms-x.phpMCE 2016 - S. Filippini - LUVE

MCE 2016 - S. Filippini - LUVECentro Studi Galileo

Ėý

LU-VE has experience producing heat exchangers for refrigeration and HVAC, especially with natural refrigerants like CO2. They presented on CO2 heat exchangers and their work on the NXTHPG project. Their CO2 test facility in Europe allows them to test heat exchangers under stationary conditions. Software predictions of capacity and pressure drop generally match test results well within 10%. Testing of CO2 evaporators showed capacity increases with Reynolds number as expected. Their 5mm tube CO2 coil for the NXTHPG project was smaller and lighter than the standard design while maintaining performance. CFD analysis helped optimize the fan configuration to increase COP by 2%.Project 1 ME 4J03

Project 1 ME 4J03Shaun Chiasson

Ėý

This document summarizes a mechanical engineering student's project analyzing mixing of hot and cold air flows in a duct. The student performed an energy balance to determine if mixing the flows to 200°C was feasible. Grid independence studies and numerous design attempts were made before achieving a final design that almost met criteria, with exit temperature within 12°C of the goal and pressure drop 34Pa over the limit. The challenges around recirculation and difficulty meeting the strict limitations were also discussed.Energy Savings from Air Sealing Large Buildings

Energy Savings from Air Sealing Large BuildingsCenter for Energy and Environment

Ėý

The document summarizes research on air sealing commercial buildings to reduce energy use. It discusses methods for measuring air leakage, findings from whole-building air leakage tests of 387 commercial buildings in the US, and a study on air sealing 7 Minnesota buildings. On average, US buildings leak 0.72 cfm/ft2 but tighter construction (<0.25 cfm/ft2) can reduce infiltration by 70% and energy use by 5-20%. The Minnesota study found sealing reduced leakage in all 7 buildings to below the standard of 0.25 cfm/ft2.Final Expo Poster_Team 24

Final Expo Poster_Team 24Christine Martini

Ėý

- Researchers at the NEXT Lab are developing a thermosiphon cooling system as an alternative to water-intensive cooling for power plants. The thermosiphon uses radiative cooling to induce internal fluid flow without requiring a large temperature difference.

- Testing of a prototype thermosiphon revealed it could achieve the low heat flux target of 100 W/m2 but had issues with non-uniform temperatures and low fluid flow rates. Improvements were needed to the design and manufacturing process.

- Further testing is required to fully understand the relationships between heat flux, fluid flow rates, and the cooling surface angle to optimize the thermosiphon design.Non-Destructive Testing: Using the Maturity Method & Alternatives to Coring

Non-Destructive Testing: Using the Maturity Method & Alternatives to CoringJill Reeves

Ėý

A presentation given during the 39th Annual NCPA Concrete Paving Workshop. By Dale Harrington, CP Tech CenterTeam Fiddle Final Presentation

Team Fiddle Final Presentationnyc9630

Ėý

The document summarizes a student project to design and test a flow-blurring fuel injector. It outlines the team members and their roles, describes flow-blurring fuel injection technology, and details the goals, design, and testing plan for the project. The team's injector design uses Solidworks and 3D printing, and their testing setup measures spray characteristics at varying air-to-liquid ratios and height-to-diameter ratios using photography and flow meters. Preliminary results show flow-blurring produces better atomization than flow-focusing. The team recommends further testing with high-speed cameras and manufacturing injectors from transparent or metallic materials.Reformer Tube Metallurgy: Design Considerations; Failure Mechanisms; Inspecti...

Reformer Tube Metallurgy: Design Considerations; Failure Mechanisms; Inspecti...Gerard B. Hawkins

Ėý

Design principles

Recent developments in metallurgy

Failure mechanisms

Monitoring and inspection techniques

Gas Lift Optimization and Troubleshooting

Gas Lift Optimization and Troubleshooting Bailey LeRoux

Ėý

This document provides an overview of gas-lift optimization and troubleshooting. It discusses identifying underperforming wells using metrics like the well performance factor and target injection differential. It then covers optimizing wells by adjusting injection gas rates, removing surface restrictions, redesigning the system, and adding secondary lift. Common inlet, outlet, and downhole problems are outlined along with tests and adjustments to address issues. Tuning the well for continuous flow is also described. Finally, tools for surface and subsurface data collection to aid in troubleshooting are listed.5 Must Know Types of Concrete Testing for Civil Engineers

5 Must Know Types of Concrete Testing for Civil EngineersSHAZEBALIKHAN1

Ėý

The five concrete tests explained in the article are basic and must do. The tests methods, procedures, relevant code are mentioned. Workability test, temperature test, setting time test, compressive strength test, permeability test. Justifying a GEP Stack Height Taller than the EPA Formula Height

Justifying a GEP Stack Height Taller than the EPA Formula HeightRon Petersen, PhD, CCM, FASHRAE

Ėý

Air monitoring data for the City of Rhinelander, WI shows SO2 concentrations exceeding the 1-hour standard at the water tower monitoring location (WTM) and, as a result, this area has been designated a SO2 non-attainment area. An analysis of emission sources and air quality modeling indicates that the Expera Rhinelander Mill 63 m tall cyclone boiler stack (S09) appears to be the primary contributor to the ambient air impact at this monitor. One solution being evaluated for showing compliance with the 1-hr SO2 NAAQS is raising the 63 m tall S09 stack to the GEP stack height. Based on the Boiler 7 building dimensions the formula GEP stack height is 75 m.

After investigating the Expera Rhinelander Mill building geometry, it was noticed that the Boiler 7 building corner is directly upwind of the stack when the wind blows directly toward the WTM. When the wind blows along a building corner, building corner vortices are generated that enhance building downwash by as much as a factor of two over that observed for wind directions normal to a building face. Past wind tunnel results suggest that the actual GEP stack height could be up to 95 m for this corner vortex situation. Hence, the purpose of this study was to determine the actual GEP stack height for the Expera Rhinelander Mill cyclone boiler stack (S09) using wind tunnel modeling.

This paper provides detailed information on determining GEP stack height, outlines the wind tunnel modeling method required to demonstrate a GEP stack height taller than the EPA formula height and provides detailed results documenting that a 90 m stack height is creditable as GEP which is well above the 75 m EPA formula height. As part of the GEP stack height demonstration, results are provided that document that the wind tunnel simulation provides similar turbulence and dispersion characteristics as the atmosphere.super air meter

- 1. A New Test Method to Measure the Freeze Thaw Durability of Fresh Concrete Braden Tabb, Robert Felice, John Michael Freeman, Robert Frazier, David Welchel Tyler Ley, P.E., Ph. D

- 2. Acknowledgements âĒ Oklahoma Transportation Center âĒ CP Tech Center âĒ Portland Cement Association

- 3. Summary âĒ Some basics of air entrained concreteâĶ âĒ The Super Air Meter âĒ The future

- 6. Why Do We Add Air to Concrete? âĒ Air-entrained bubbles are the key to the freeze-thaw resistance of concrete Air volume = Freeze Thaw Performance âĒ Smaller bubbles are more effective in providing freeze-thaw resistance than larger bubbles

- 7. âĒ Volume of air provided is the same for both circumstances. âĒ Case B has a lower spacing factor and a higher specific surface. A B What Do You Want in an Air-Void System?

- 8. A B âĒ Volume of air provided is the same for both circumstances. âĒ Case B has a lower spacing factor and a higher specific surface. What Do You Want in an Air-Void System?

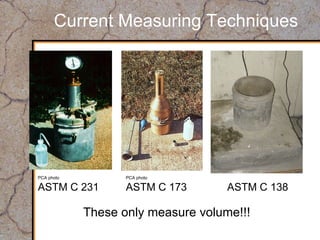

- 9. Current Measuring Techniques PCA photo ASTM C 231 PCA photo ASTM C 173 ASTM C 138 These only measure volume!!!

- 10. Hardened Air Void Analysis From Hover

- 11. Hardened Air Void Analysis From Hover

- 12. Open symbols failed ASTM C666 0.004 0.006 0.008 0.010 0.012 0.014 0.016 0.018 0.020 0.022 0.024 2.0% 3.0% 4.0% 5.0% 6.0% 7.0% 8.0% 9.0% SpacingFactor(in) Air Content of Concrete (Pressure) No Polycarboxylate Open symbols failed ASTM C666 Freeman et al., 2012

- 13. 0.004 0.006 0.008 0.010 0.012 0.014 0.016 0.018 0.020 0.022 0.024 2.0% 3.0% 4.0% 5.0% 6.0% 7.0% 8.0% 9.0% SpacingFactor(in) Air Content of Concrete (Pressure) No Polycarboxylate Polycarboxylate Open symbols failed ASTM C666 Freeman et al., 2012

- 14. 0% 1% 2% 3% 4% 5% 6% 7% 8% 9% 10% 0-10 10-20 20-30 30-40 40-50 50-60 60-70 70-80 80-90 90-100 100-110 110-120 120-130 130-140 140-150 150-160 160-170 170-180 180-190 190-200 200-210 210-220 220-230 230-240 240-250 250-260 260-270 270-280 280-290 290-300 300-310 310-320 320-330 330-340 340-350 350-360 360-370 370-380 380-390 390-400 400-410 410-420 420-430 430-440 440-450 450-460 460-470 470-480 480-490 490-500 500-550 550-600 600-650 650-700 700-750 750-800 800-850 850-900 900-950 950-1000 1000-1200 1200-1400 1400-1600 1600-1800 1800-2000 2000+ normalizedAirContentFraction Chord Size, microns WROS Only PC1 + WROS Freeman et al., 2012 small voids large voids

- 15. 0% 1% 2% 3% 4% 5% 6% 7% 8% 9% 10% 0-10 10-20 20-30 30-40 40-50 50-60 60-70 70-80 80-90 90-100 100-110 110-120 120-130 130-140 140-150 150-160 160-170 170-180 180-190 190-200 200-210 210-220 220-230 230-240 240-250 250-260 260-270 270-280 280-290 290-300 300-310 310-320 320-330 330-340 340-350 350-360 360-370 370-380 380-390 390-400 400-410 410-420 420-430 430-440 440-450 450-460 460-470 470-480 480-490 490-500 500-550 550-600 600-650 650-700 700-750 750-800 800-850 850-900 900-950 950-1000 1000-1200 1200-1400 1400-1600 1600-1800 1800-2000 2000+ normalizedAirContentFraction Chord Size, microns WROS Only PC1 + WROS Look at the difference in the volume of the air voids!!! Freeman et al., 2012 small voids large voids

- 16. Summary âĒ It is common to require a certain volume of air in concrete in order to obtain freeze thaw durability âĒ The volume of air does not equal air void system quality âĒ Although, a hardened air void analysis (ASTM C 457) can measure the air- void quality it is not practical to run regularly

- 17. What do we need? âĒ We need a test that can quantify air- void systems quickly in fresh concrete âĒ Investigate a sample of significant size âĒ Economical âĒ Field ready

- 18. Super Air Meter (SAM) âĒ We have modified a typical ASTM C 231 pressure meter so that it can hold larger pressures âĒ We have replaced the typical gage with a digital one âĒ The test takes 8 minutes

- 20. How does it work? âĒ Use ASTM C 231 procedures to fill the measurement bowl âĒ Secure the lid âĒ Add water through the petcocks

- 22. 0 15 30 45 60 75 90 0 AppliedPressure(psi) Time Top Chamber, Pc1 Bottom Chamber, Pa1 Equilibrium Pressure, P2 When both chambers are in contact with one another Top Chamber Bottom Chamber

- 23. 0 15 30 45 60 75 90 0 AppliedPressure(psi) Time Top Chamber, Pc1 Bottom Chamber, Pa1 Equilibrium Pressure, P2 When both chambers are in contact with one another

- 24. 0 15 30 45 60 75 90 0 AppliedPressure(psi) Time Top Chamber, Pc1 Bottom Chamber, Pa1 Equilibrium Pressure, P2 When both chambers are in contact with one another

- 25. 0 15 30 45 60 75 90 0 AppliedPressure(psi) Time Top Chamber, Pc1 Bottom Chamber, Pa1 Equilibrium Pressure, P2 When both chambers are in contact with one another release pressure in both chambers

- 26. 0 15 30 45 60 75 90 0 AppliedPressure(psi) Time Top Chamber, Pc1 Bottom Chamber, Pa1 Equilibrium Pressure, P2 When both chambers are in contact with one another

- 27. 0 15 30 45 60 75 90 0 AppliedPressure(psi) Time Top Chamber, Pc1 Bottom Chamber, Pa1 Equilibrium Pressure, P2

- 28. How does it work? âĒ We use an algorithm to find a SAM number. âĒ The SAM number correlates to air void distribution âĒ The meter also measures air volume

- 29. How can we prove it? âĒ We made 95 concrete mixtures âĒ Different AEAs âĒ Combinations of AEAs and PCs âĒ Different w/cm (0.39 - 0.53) âĒ Slumps from 0.25â to 10â âĒ Air contents from 1.25% to 10% âĒ Hardened air void analysis (ASTM C 457) was completed on each mixture âĒ Values were compared to the SAM number

- 31. 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Modulus(%) SAM Number SAM Number PASS FAIL

- 32. Observations âĒ When the SAM number is below 0.2 then the spacing factor is below 0.008â for 90% of the samples and 98% of the samples had a spacing factor below 0.010â âĒ The SAM number seems to correlate with the amount of small bubbles in the sample

- 33. How Consistent Is It? âĒ We ran the following on each of the 95 mixtures with two separate SAMs: â Air contents â SAM numbers â ASTM C 457 hardened air void analysis â Unit Weight

- 34. y = 1.015x - 0.0227 RÂē = 0.9932 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 SAM2AirContent(%) SAM 1 Air Content (%) Mean Difference -0.005% Standard dev. 0.064%

- 35. Mean Difference 0.006 Standard dev. 0.049

- 37. y = 0.9982x + 0.2504 RÂē = 0.9668 y = 0.9965x + 0.3611 RÂē = 0.9651 0 1 2 3 4 5 6 7 8 9 10 0 1 2 3 4 5 6 7 8 9 10 SuperAir(%) Gravimetric Calculated Air (%)

- 38. Conclusions âĒ The SAM test can be completed in about 10 minutes with fresh concrete âĒ A SAM number of 0.20 seems to correlate with the ASTM C 457 spacing factor of 0.008â and freeze thaw durability as per ASTM C 666 âĒ Two SAMs have been shown to provide consistent results.

- 39. www.superairmeter.com SAMs should be available April 2014

- 40. Questions???