Supply chain management Collaboration

- 1. Pia Bosma MSc SUPPLY CHAIN MANAGEMENT

- 2. Content Lecture Collaboration Basics of Supply Chain Management The evolving Supply Chain Analysing Relationships Questions Inter-organizational Relationships Assignments

- 3. What Is the Supply Chain? ’ü« Also referred to as the logistics network ’ü« Suppliers, manufacturers, warehouses, distribution centers and retail outlets ŌĆō ŌĆ£facilitiesŌĆØ and the Suppliers Manufacturers Warehouses & Distribution Centers Customers ’ü« Raw materials ’ü« Work-in-process (WIP) inventory ’ü« Finished products that flow between the facilities Transportatio Transportation n Costs Material Costs Costs Transportation Manufacturing Costs Costs Inventory Costs

- 4. The Supply Chain ŌĆō Another View Plan Plan Source Source Make Make Deliver Deliver Buy Buy Suppliers Manufacturers Warehouses & Customers Distribution Centers Transportation Transportation Material Costs Costs Costs Transportation Manufacturing Costs Inventory Costs Costs

- 5. Illustration of the supply chain network, using Braun Oral-B as an example

- 6. What Is Supply Chain Management (SCM)? Plan Source Make Deliver Buy ’ü« A set of approaches used to efficiently integrate ŌĆō Suppliers ŌĆō Manufacturers ŌĆō Warehouses ŌĆō Distribution centers ’ü« So that the product is produced and distributed ŌĆō In the right quantities ŌĆō To the right locations ŌĆō And at the right time ’ü« System-wide costs are minimized and ’ü« Service level requirements are satisfied

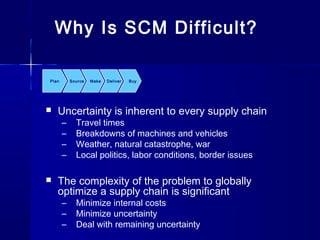

- 7. Why Is SCM Difficult? Plan Source Make Deliver Buy ’ü« Uncertainty is inherent to every supply chain ŌĆō Travel times ŌĆō Breakdowns of machines and vehicles ŌĆō Weather, natural catastrophe, war ŌĆō Local politics, labor conditions, border issues ’ü« The complexity of the problem to globally optimize a supply chain is significant ŌĆō Minimize internal costs ŌĆō Minimize uncertainty ŌĆō Deal with remaining uncertainty

- 8. TodayŌĆÖs Marketplace Requires: Shared visibility for trading partners ’ü« Personalized content and services for their customers ’ü« Collaborative planning with design partners, distributors, and suppliers ’ü« Real-time commitments for design, production, inventory, and transportation capacity ’ü« Flexible logistics options to ensure timely fulfillment ’ü« Order tracking & reporting across multiple vendors and carriers

- 9. Content Lecture Collaboration Basics of Supply Chain Management The evolving Supply Chain Analysing Relationships Questions Inter-organizational Relationships Assignments

- 10. Supply Chain Integration ŌĆō Push Strategies ’ü« Classical manufacturing supply chain strategy ’ü« Manufacturing forecasts are long-range ŌĆō Orders from retailersŌĆÖ warehouses ’ü« Longer response time to react to marketplace changes ŌĆō Unable to meet changing demand patterns ŌĆō Supply chain inventory becomes obsolete as demand for certain products disappears ’ü« Inefficient use of production facilities (factories) ŌĆō How is demand determined? Peak? Average? ŌĆō How is transportation capacity determined? ’ü« Examples: Auto industry, large appliances, others?

- 11. Supply Chain Integration ŌĆō Pull Strategies ’ü« Production and distribution are demand-driven ŌĆō Coordinated with true customer demand ’ü« None or little inventory held ŌĆō Only in response to specific orders ’ü« Fast information flow mechanisms ŌĆō POS data ’ü« Decreased lead times ’ü« Decreased retailer inventory ’ü« Decreased variability in the supply chain and especially at manufacturers ’ü« Decreased manufacturer inventory ’ü« More efficient use of resources ’ü« More difficult to take advantage of scale opportunities ’ü« Examples: Dell, Amazon

- 12. Supply Chain Integration ŌĆō Push/Pull Strategies ’ü« Hybrid of ŌĆ£pushŌĆØ and ŌĆ£pullŌĆØ strategies to overcome disadvantages of each ’ü« Early stages of product assembly are done in a ŌĆ£pushŌĆØ manner ’ü« Final product assembly is done based on customer demand for specific product configurations ’ü« Supply chain timeline determines ŌĆ£push-pull boundaryŌĆØ Push- Pull ŌĆ£GenericŌĆØ Product Boundary ŌĆ£CustomizedŌĆØ Product Push Strategy Pull Strategy Raw End Materials Consumer Supply Chain Timeline

- 13. Choosing Between Push/Pull Strategies Pull High Where do the Industries where: Industries where: following industries fit ŌĆó Customization is High ŌĆó Demand is uncertain in this model: ŌĆó Demand is uncertain ŌĆó Scale economies are High ŌĆó Scale economies are Low ŌĆó Low economies of scale ’ü« Automobile? Demand Uncertainty ’ü« Aircraft? Computer Furniture equipment ’ü« Fashion? ’ü« Petroleum refining? ’ü« Pharmaceuticals? Industries where: Industries where: ’ü« Biotechnology? ŌĆó Uncertainty is low ŌĆó Standard processes are the ’ü« Medical Devices? ŌĆó Low economies of scale norm ŌĆó Push-pull supply chain ŌĆó Demand is stable ŌĆó Scale economies are High Books, CD ŌĆÖs Grocery, Beverages Push Low Low Economies of Scale High Pull Push

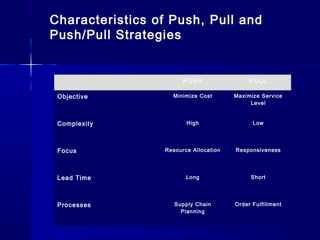

- 14. Characteristics of Push, Pull and Push/Pull Strategies PUSH PULL Objective Minimize Cost Maximize Service Level Complexity High Low Focus Resource Allocation Responsiveness Lead Time Long Short Processes Supply Chain Order Fulfillment Planning

- 15. Supply Chain Collaboration ŌĆō What Is It? ’ü« Many different definitions depending on perspective ’ü« The means by which companies within the supply chain work together towards mutual goals by sharing ŌĆō Ideas ŌĆō Information ŌĆō Processes ŌĆō Knowledge ŌĆō Information ŌĆō Risks ŌĆō Rewards ’ü« Why collaborate? ŌĆō Accelerate entry into new markets ŌĆō Changes the relationship between cost/value/profit equation

- 16. Supply Chain Collaboration ’ü« Cornerstone (= something very important that something else depends on) of effective SCM ’ü« The focus of many of todayŌĆÖs SCM initiatives Retailers Suppliers Synchronized Manufacturer Production Scheduling Collaborative Distributors/ Demand Collaborative Wholesalers Planning Product Development Collaborative Logistics Planning ŌĆóTransportation services ŌĆóDistribution center services Logistics Providers 16

- 17. Benefits of Supply Chain Collaboration CUSTOMERS MATERIAL SERVICE SUPPLIERS SUPPLIERS ’ü« Reduced inventory ’ü« Reduced inventory ’ü« Lower freight costs ’ü« Increased revenue ’ü« Lower warehousing costs ’ü«Faster and more reliable ’ü« Lower order management ’ü« Lower material acquisition delivery costs costs ’ü« Lower capital costs ’ü« Higher Gross Margin ’ü« Fewer stockout conditions ’ü« Reduced depreciation ’ü« Better forecast accuracy ’ü« Lower fixed costs ’ü« Better allocation of promotional budgets ’ü« Improved customer service ’ü« More efficient use of human resources

- 18. Supply Chain Collaboration Spectrum Extensive Not Viable Synchronized ’ü« Thegreen arrow Collaboration describes increasing complexity and sophistication of: ŌĆō Information systems Extent of Collaboration ŌĆō Systems infrastructure ŌĆō Decision support systems Coordinated ŌĆō Planning mechanisms Collaboration ŌĆō Information sharing ŌĆō Process understanding ’ü« Higher levels of Cooperative collaboration imply the Collaboration need for both trading partners to have equivalent (or close) levels of supply chain maturity ’ü« Synchronized Transactional collaboration demands Limited Collaboration Low Return joint planning, R&D and sharing of information Many Few and processing models Number of Relationships ŌĆō Movement to real-time customer demand information throughout the Source: Cohen & Roussel supply chain 18

- 19. Successful Supply Chain Collaboration ’ü« Try to collaborate internally before you try external collaboration ’ü« Help your partners to work with you ’ü« Share the savings ’ü« Start small (a limited number of selected partners) and stay focused on what you want to achieve in the collaboration ’ü« Advance your IT capabilities only to the level that you expect your partners to manage ’ü« Put a comprehensive metrics program in place that allows you to monitor your partnersŌĆÖ performance ’ü« Make sure people are kept part of the equation ŌĆō Systems do not replace people ŌĆō Make sure your organization is populated with competent professionals whoŌĆÖve done this before

- 20. Content Lecture Collaboration Basics of Supply Chain Management The evolving Supply Chain Analysing Relationships Questions Inter-organizational Relationships Assignments

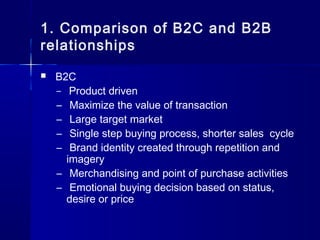

- 21. 1. Comparison of B2C and B2B relationships ’ü« B2C ŌĆō Product driven ŌĆō Maximize the value of transaction ŌĆō Large target market ŌĆō Single step buying process, shorter sales cycle ŌĆō Brand identity created through repetition and imagery ŌĆō Merchandising and point of purchase activities ŌĆō Emotional buying decision based on status, desire or price

- 22. 1. Comparison of B2C and B2B relationships ’ü« B2B ŌĆō Relationship driven ŌĆō Maximize the value of the relationship ŌĆō Small, focused target group ŌĆō Multi-step buying process, longer sales cycle ŌĆō Brand identity created on personal relationship ŌĆō Educational and awareness building activities ŌĆō Relational buying decision based on business value

- 23. Relations hips in the value

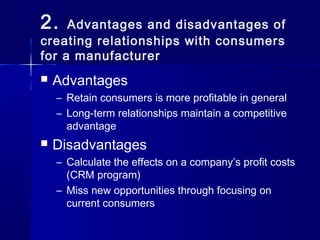

- 24. 2. Advantages and disadvantages of creating relationships with consumers for a manufacturer ’ü« Advantages ŌĆō Retain consumers is more profitable in general ŌĆō Long-term relationships maintain a competitive advantage ’ü« Disadvantages ŌĆō Calculate the effects on a companyŌĆÖs profit costs (CRM program) ŌĆō Miss new opportunities through focusing on current consumers

- 25. 3. Motorola and Hewlett- Packard ’ü« Co-opetition ’üŻ if both elements of cooperation and competition are visible, the relationship between the competitors is named co-opetition. ŌĆō A firm with a strong position, but lacking resources held by the competitor must focus on a co-opetitive relationship. ŌĆō Within the process, firms develop mechanisms that attempt to deal with competitiveness

- 26. Five types of relationship between a firm and its competitor

- 27. 4. Properly incorporating suppliers in their product development process ’ü« Suppliers can do much more than deliver reasonably priced items on request. ’ü« Exploiting some of the potential of a supplier requires that operations of the two companies become more closely integrated in the various facets of the relationship.

- 28. 5. A manufacturer how wants to integrate end-consumers in the product development process ’ü« Formal way: conjoint analysis ’ü« Informal way: sales representative comes home to the HQ with some inspiration for the new product development

- 29. 6. How can ŌĆśdistanceŌĆÖ be reduced in cross-cultural buyer-seller negotiations ’ü« Cultural dimensions that affect the distance: ŌĆō Different understanding of the national and industry culture ŌĆō Different understandings of the organisational culture ŌĆō Different personal behaviour because of the different mental programming

- 30. 6. How can ŌĆśdistanceŌĆÖ be reduced in cross-cultural buyer-seller negotiations ’ü« It is possible to reduce the ŌĆśpsychic distanceŌĆÖ by an intercultural learning process. In this learning process, the company transfers knowledge about reduction of ŌĆśpsychic distancesŌĆÖ in different cultures ŌĆō Psychic: Having a special mental ability, for example so that you are able to know what will happen in the future or know what people are thinking

- 31. 7. Dell entered into a relationship with IBMŌĆÖs Global Service Division ’ü« Dell has maybe evaluated is own competences and realised that service support is not its core competence. It is better in PC-manufacturing. Therefore, it has outsourced the service support to IBM, which sees this as one of its existing and future core competences. That is a relationship of value for both partners.

- 32. 8. Describe the interactions between buyer and seller in the ŌĆśdiamondŌĆÖ model ’ü« In the ŌĆśdiamondŌĆÖ model, the boundaries between buying and selling firms become more transparent. Interactive, cross functional teams openly exchange ideas for improving efficiency and effectiveness. The goal is to create new value together.

- 33. Organisation of buyerŌĆōseller relationship

- 34. Content Lecture Collaboration Basics of Supply Chain Management Efficient consumer response Analysing Relationships Questions Inter-organizational Relationships Assignments

- 35. Summary Inter- organizational relationships ’ü« The network perspective on supply chains requires a holistic approach. (dealing with of treating with the whole of something) ’ü« It recognizes the interdependence not only of immediate partners but also among the entire network of relationships

- 36. Summary Inter- organizational relationships ’ü« The movement of organizations toward network relationships places new challenges on management ŌĆō to define the core and establish the boundaries of the firm ŌĆō to create the most effective governance mechanism ŌĆō to develop the most appropriate relationships with partners

- 37. Summary Inter- organizational relationships ’ü« Trust relationships are a necessary condition in supply chain management. Without it, partners wonŌĆÖt share information or commit to specific high-risk investments. ŌĆō It is time consuming and is based on building positive experience

- 38. Summary Inter- organizational relationships ’ü« The essential characteristics of the supply chain is its inter-organizational relationships. The ability to develop and manage the supply chain becomes a core competency, along with product technology, knowledge, and market access these relationships govern future actions of the corporation.

- 39. Content Lecture Collaboration Basics of Supply Chain Management Efficient consumer response Analysing Relationships Questions Inter-organizational Relationships Assignments

- 40. Assignments: Innovation and entrepreneurship ’ü« Working assignments 1 and 2 ’ā© Page 9 ’ü« Question: Are large firms better innovators than small firms ’ā© Page 10 ’ü« Questions: Skype: innovators and entrepreneurs ’ā© Page 13 ’ü« Article: Innovation Management in Supply Chains ’ā© Summary

- 41. BenettonŌĆÖs Supply networksŌĆÖ ’ü« Assignment ŌĆō Combine several subjects in a professional report. The size of the report must not exceed 5 A4, excluding the cover, contents and appendixes. ’ü« Then there will be at the end a talk of around 30 minutes about the report