Sustaining Nuclear Infrastructure Wna China Nov10

- 1. Sustainable Lifecycle Information.Jean-Baptiste Monnier, PhDSenior VP, Bentley Asia

- 2. Introduction to BentleyIntegration of data using new ISO data formatsLeveraging engineering data into construction work packages.Data Lifecycle in OperationsAgenda

- 3. About BentleyBentley is the global leader dedicated to providing architects, engineers, constructors, and owner-operators with comprehensive software solutions for sustaining infrastructure. Global Business:Nearly 3,000 colleagues in 45 countries

- 4. $500 million in annual revenuesA few of our Nuclear Solution users? 2008 Bentley Systems, Incorporated

- 5. Integration of data using new ISO data formats5 | WWW.BENTLEY.COM

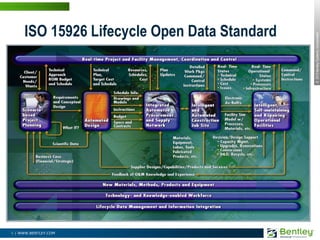

- 6. ISO 15926 Lifecycle Open Data Standard

- 7. What is ISO 15926?Information concerning engineering, construction and operation of production facilities is created, used and modified by many different organizations throughout a facility's lifetime. The purpose of ISO 15926 is to facilitate integration of data to support the life-cycle activities and processes of production facilities.

- 8. Data model suitable for shared databases or data warehouse computer systems in development project Data model for product catalogues & procurementIn operation and maintenance: To support the information requirements in all phases of a plant's life-cycle and the sharing and integration of information amongst all parties involved in the plant's life cycle.How is ISO 15926 used?

- 9. Interoperabilty during design phaseBetween systemsBetween project groupsHandover flexibility & benefitsInteroperabiliy during operationsReliabilty of data forma (plants live ~60 years)Reduced cost of softwareOpenPlant from Bentley first solution on ISO 15926Benefits of open data format ISO 15926?

- 10. Leveraging engineering data into construction work packages.

- 11. Beijing Huahui Technical Development Co., Ltd. is controlled by CNECC.CANPPE2 now is widely used in at least 12 nuclear power plants such as Hongyanhe, Fuqing and AP1000, etc.CANPPE2Huahui now is working with Bentley to build a Nuclear Power Plant 3D Construction Management System by integrated with CANPPE2 and ConstructSim.

- 12. Data Lifecycle in Operations

- 13. Data lifecycle ensures that?information assets are governed, secure,?controlled and can be trusted ¨C?delivering relevant information in context?to your business users ¨C turning information into a corporate asset, not a liability.

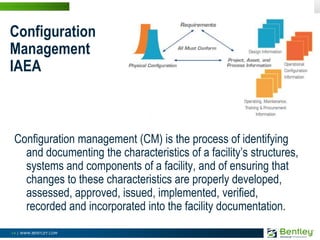

- 14. ConfigurationManagementIAEAConfiguration management (CM) is the process of identifying and documenting the characteristics of a facilityˇŻs structures, systems and components of a facility, and of ensuring that changes to these characteristics are properly developed, assessed, approved, issued, implemented, verified, recorded and incorporated into the facility documentation.

- 15. AmerenUEˇŻs Callaway PlantNuclear Generation Solution Expanded Across the EnterpriseChallenges

- 16. Difficulty in accessing all plant related information

- 17. Best Practices review ˇ°´Úľ±˛Ô»ĺľ±˛Ô˛µˇ±

- 18. Integrity of information questionable

- 19. Cumbersome change management process

- 20. Solutions

- 21. Replaced twenty-eight legacy systems with eB

- 22. More than 80 information sources consolidated

- 23. eB maintains the plant configuration which includes the MEL and all related documents

- 24. Nuclear records management system

- 25. Integrated eB with the work management system

- 26. Optimized engineering change management process

- 28. Results

- 29. Plant workers can get rapid access to all plant information

- 30. Information is presented in ˇ°contextˇ±

- 31. Increased communications of plant personnel

- 32. Resolved with Favorable results of ˇ°´Úľ±˛Ô»ĺľ±˛Ô˛µˇ± from Best Practices review organization.

- 33. Set world record in replacement of 2 steam generators

- 34. Streamlined change management resulting in improved information integrity, regulatory, compliance, safety, efficiencyBusiness Overview:AmerenUEˇŻs Callaway Nuclear Plant in operation since 1984 was built at a cost of $3 billion. The plant produces over 1,200 megawatts of electricity ˇŞ sufficient to power 750,000 average householdsIndustryUtilitiesGeographies100 miles west of St. Louis in Missouri

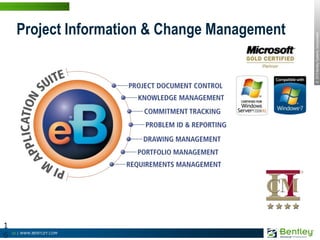

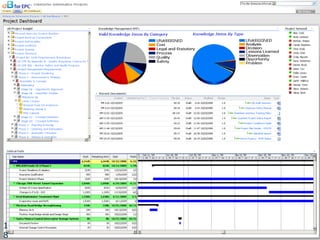

- 35. Project Information & Change Management16

- 37. 18

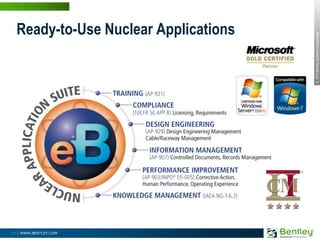

- 38. A new generation of nuclear power plants is being designed and built to address the worldˇŻs renewable energy needs. Microsoft and Bentley, a Microsoft Managed Gold Certified Partner, are providing the IT infrastructure and industry-specific software applications to support the entire information life cycle ¨C design, construct, operate, and maintain. eB for Nuclear, built entirely on Microsoft technology, takes advantage of BentleyˇŻs decades of nuclear experience and incorporates industry best practices defined by nuclear industry organizations including the NRC, INPO, CAPOG and NIRMA.Jon Arnold, Managing Director, Worldwide Power and Utilities IndustryMicrosoftMicrosoft & Bentley Partnership

- 39. Conclusions

- 40. Bentley empowers owner-operators to leverage the value of information modeling throughout operations and maintenance ¨C while maintaining the transactional integrity that their enterprise applications demand

- 41. Thank you

Editor's Notes

- #2: We have just joined WNA, and this is therefore our first conference as a memberThe illustration is the shinkori 3& 4 reactors being built in Korea, KEPCO is one of our users in the region. The 3D and intelligent engineering is done with our systems

- #4: Bentley knows a lot about infrastructure. In fact, sustaining infrastructure is all that we do and that has helped secure our standing as the worldˇŻs leading provider of software for the design, construction, and operation of infrastructure.

- #5: About half of our users are EPCˇŻs using Bentley technology for engineeringThe other half of our users are owner operators, for Configuration management, documentation, licensing Some of our users have a long history with us: over more than 10 years, at EDF Bentley solutions are used in each of the 59 reactors to update the schematic information. This information is later centralized in a server for configuration checks and for work scheduling. Here in China, each of the 3 main reactors technologies use Bentley technologies, either for 3D design, for schematics, or technical for information management In China, BentleyIn nuclear power engineeringIn fuel processingIn miningIn decommissionning

- #10: Two active projects at EPRI on 15926 recognized by EPRI as neutral data handover strategy (Ref: Advanced Nuclear Technology: New Nuclear Power Plant Information Handover Guide, Final Report 2009)AEX deployment by EPRI, schema alignment with 15926 RDL (Ref: Automated Equipment Exchange Project)Some of the leaders in the industry areDominion Power (US)AECL (Canada)Rosatom (Russia)AREVA (France, on behalf of a number of its potential customers)

- #15: One of the use case in nuclear energy is configuration managementTypical starts during engineernig and follows over during the live cycleWhat is should be (this is the regulator, the plant as viewed by the regulator)What we stay it is (this is technical documentation & engineering data, the digital plant)What it is (the physical plant as it stands)

- #16: INPO had down-rated the plant based on various shortcomings and a perceived lack of rigor in some of its processes? The plant required major upgrades to replace aging equipment and restore the plant to its full generation capacity? An aging workforce and loss of experienced staff jeopardized the future operation of the plantRegain their outstanding INPO rating by 2006 ? Replace four steam generators at a cost of $300 million in 2005? Regain their status of being one of the most efficient and safe nuclear plants in the industryApproximately 900 people working at the plant use eB on a daily basis to capture, retrieve, and view one or more of over three million documents, drawings, records, component data, and other information. Greatly enhanced records management process - Automatically captured and transferred records in electronic form from multiple applications- Significantly reduced labor-intensive manual process to scan, QC, index and store paper based records- Quality of records much better because they are generated in electronic form and stored in pdf- Considerable cost savings from reduction in use of paper and need for storage space- Increased value of records and reduced associated risks because of contextual links to other entities- Improved productivity because of rapid retrieval of records from any desktop? Improved rigor of information management processes, especially engineering design change management process- Full visibility of the impact of any change improves decision making and reduces risk- Tracks approved changes to completion- Improved information integrity- Change process complies with industry best practice AP 929 standard design change management process ? Consolidated multiple applications on a single, modern platform- Streamlined business processes- Information accessible from and to other applicationsˇ°eB has greatly improved our ability to retrieve records rapidly, and to see and use what we look at.ˇ± ˇŞRandy Bisig, Operations Supervisor AmerenUE Callaway Plant

- #17: In addition to core enterprise information management capabilities, eB offers a set of coordinated applications developed around EPC standards and industry best practices. In particular IˇŻd like to point out Portfolio Management. Your organizations are managing hundreds, maybe thousands, of projects simultaneously. With eB you can streamline new project start ups by using requirement structures and other common elements from past projectsˇsaving you time, money and ensuring consistency in reporting. The eB for EPC solution suite will support quick and reduced costs for implementations, a community that provides input for knowledge sharing and product improvement, and is proven on large scale projects.

- #19: The Solution: eB for EPCeB is an information management system that connects and manages every piece of information related to your project, ensuring that itˇŻs all up-to-date, visible, and secure. The result is an integrated Project Management Information Solution that improves communication and simplifies collaboration by making trustworthy information accessible when and where it is needed to support the project. In short, eB is the smartest, easiest, most-comprehensive way to manage project information, people, processes, and risk. A global EPC company has achieved project milestone completions continually 20% ahead of schedule and up to 10% below budget, through the application of eB. With eB, EPC organizations realize the following benefits:Information accuracy is vastly improved and can be trusted for business operationsInformation modeling identifies who is responsible for information, what the information describes, where it is located and what it is related to, making for faster and better business decisions Automated classification of information enforces information governance, policies and controlsPowerful records management securely stores all paper and electronic records with defined retention and disposition rules to ensure regulatory compliance Contextual search, retrieval, viewing, and printing of documents and records increases productivity and efficiencyIntegration with other business applications streamline processes and eliminate discreet, disparate repositories of informationMaking informed decisions based on the use of the eB change effects analysis function allows managers to ensure that all affected information is taken into account when planning and managing changes.Project closure is often affected by delays in providing all of the necessary information specified in contracts¨CeB has built-in functions to improve project information handover to streamline project completion.