Swe l-8-earthen channels and under ground pipe line

- 2. L-8 Earthen channels Advantages and disadvantages of Earthen channel, Advantages of lining the channels. Underground pipeline over Earthen channels Contents 1. Earthen channels 2. Advantages and disadvantages of Earthen channel 3. lining the channels 4. Materials for channel lining 5. Underground pipeline 6. Key points

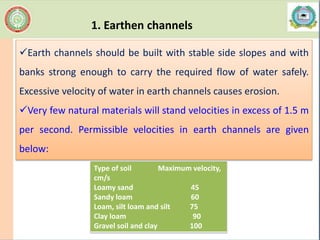

- 3. ?Earth channels should be built with stable side slopes and with banks strong enough to carry the required flow of water safely. Excessive velocity of water in earth channels causes erosion. ?Very few natural materials will stand velocities in excess of 1.5 m per second. Permissible velocities in earth channels are given below: 1. Earthen channels Type of soil Maximum velocity, cm/s Loamy sand 45 Sandy loam 60 Loam, silt loam and silt 75 Clay loam 90 Gravel soil and clay 100

- 4. ?Major disadvantage seepage losses ?Sandy soils and fields infested with rodents and burrowing animals ?Central Water and Power Commission 71%

- 5. Channels without artificial lining of bed or sides are called earth channels. The advantages of earth channels are: (i) They are understood and accepted by the farmers (ii) They can be built and maintained by unskilled persons (iii) They require no special equipment or materials 2. Advantages and disadvantages of Earthen channel

- 6. The low initial cost constitutes the major advantage of earth channels. The disadvantages of earth channels are: (a) Excessive seepage losses (b) Low velocities due to retardance of flow by rough surfaces (c) Susceptibility to erosion and therefore, relatively large cross- sectional areas are required (d) Danger of breaks due to erosion and burrowing animals (e) Growth of aquatic weeds which reduce velocity (f) High labour requirements for maintenance. 2. Advantages and disadvantages of Earthen channel

- 7. lining to the irrigation channels to serve the following purposes: a) Reduces or eliminates water loss due to seepage b) Prevents weed growth and increases the carrying capacity of water c) Provides safety against breaks d) Prevents scouring of the channel e) Reduces labour requirement for maintenance of the channel f) Discharge increases due to reduction of roughness coefficient, g) Reduced drainage problem h) Being non-erodible, best hydraulic section can be designed. 3. lining the channels

- 8. If the cost of water production is not high and seepage loss is not excessive in a location, the farmer may not go for lining. Before going for lining, the following two important factors should be taken into consideration: (i) annual cost for lining and (ii) (ii) annual cost of water saved.

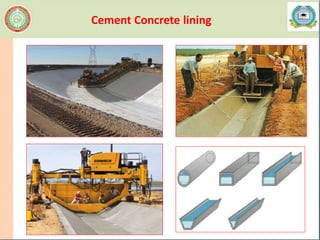

- 9. 4. Materials for channel lining concrete, stone or brick masonry, rock masonry, clay tiles, pre-cast RCC sections, asphalt membrane, synthetic rubber membrane, agri-film Well mixed and well made cement concrete lining and also single layer bricks or stones laid in cement or lime mortar provide virtually water-proof channel lining

- 10. Cement Concrete lining ?Steep side slopes of 1:1 or 3:4 ?compacted 15 cm layer. ?The top width of the embankment 40 to 45 cm. ? A freeboard of at least 5 cm ?They should not normally exceed 1 to 1. ?The thickness of concrete lining commonly used is 4-5 cm. ?The concrete mixture recommended 1:3:4 (cement: sand: gravel). ?Intervals between joints should not be greater than 2 m.

- 12. Pre-cast concrete channels ?Pre-cast concrete channels may be constructed with concrete ¡°half pipes¡± ?Once the embankment is built and the channel excavated, ?Low cost concrete channel sections can be made in a U- shaped wooden form by tamping 1: 3: 4 (cement: sand: gravel) ?The wooden form can be made by a local carpenter. ?Hard wood boards 2.5 cm thick are used to make the form ?The size of the irrigation stream

- 14. Brick or stone masonary lining ?Single layer brick or tile or rubble stone ?The bricks, tile or stones are laid flat ?The mortar should have a cement sand ratio of 1:3 ?linings are recommended discharge is more than 30 lts/s.

- 15. 5. Underground pipeline water distribution system ?Eliminates conveyance and evaporation losses ?The efficient implements and machinery ?Open channels often take 2 to 4% of the land area out of cultivation ?pipes operate under pressure, they can be laid uphill or downhill ?The pipes are not clogged by vegetation and wind-blown ?higher initial cost and not suitable under canal irrigation system ?made reinforced concrete pipes and PVC pipes. ?Small farms are non- reinforced concrete pipes.

- 16. Underground pipeline water distribution system

- 17. ?Very few natural materials will stand velocities in excess of 1.5 m per second ?Steep side slopes of 1:1 or 3:4 ?The top width of the embankment 40 to 45 cm and freeboard 5 cm ?The thickness of concrete lining commonly used is 4-5 cm. ?The concrete mixture recommended 1:3:4 (cement: sand: gravel). ?Intervals between joints should not be greater than 2 m. ?Pre-cast concrete channels may be constructed with concrete ¡°half pipes¡± ?Low cost concrete channel sections can be made in a U- shaped wooden form by tamping 1: 3: 4 (cement: sand: gravel) ?The wooden form can be made by a local carpenter. ?Hard wood boards 2.5 cm thick are used to make the form ?he mortar should have a cement sand ratio of 1:3 ?linings are recommended discharge is more than 30 lts/s Key Points¡¡.