Syrup by adk

- 2. INDEX WHAT IS SYRUP ADVANTAGES OF SYRUP TYPES OF SYRUP DISADVANTAGES OF SYRUP COMPONENTS OF SYRUP PREPARATION OF SYRUP

- 3. WHAT IS SYRUP concentrated aqueous preparations of 85% of sugar or sugar substitute with or without flavoring agents and medicinal substances. In medical terminology, medicinal syrups are nearly saturated solutions of 85% of sugar in water in which medicinal substances or drugs are dissolved. Due to the inability of some children and elderly people to swallow solid dosage forms, it is fairly common today for a pharmacist to be asked to prepare an oral liquid dosage form of a medication available in the pharmacy.

- 4. TYPESOFSYRUP Aromatic or adjuvant syrups They are mostly used to improve the taste of salty, bitter, or otherwise unpleasant mixtures. Medicinal syrups They are of two types: Made from extractive drugs: Here, the fluid extract of the respective medicines is mixed with the syrup. Made from chemicals: This can be either by simple solution or by chemical reaction and solution. Here the taste of the medicinal agents is greatly modified.

- 5. ADVANTAGES OF SYRUP ÔÇß Appropriate for any patient, whatever the age is ÔÇß The most natural and easiest route of administration ÔÇß Economical and safe to the patient ÔÇß No nursing is required, which means the patient can take it with no help ÔÇß The liquid dosage form is expected for certain types of products like cough medicines

- 6. DISADVANTAGES OF SYRUP  Delayed onset of action because absorption takes time  Not suitable in emergency and for unconscious patients  Not convenient for a patient with a gastrointestinal disorder such as diarrhea, constipation, ulceration, and hyperacidity in stomach  Can’t avoid first pass metabolism

- 7. COMPONENTS OF SYRUP Most syrups contain the following components in addition to the purified water and any medicinal agents present: (a)Sweetening Agent- the sugar, usually sucrose, or sugar substitute used to provide sweetness and viscosity (b) Antimicrobial Preservatives (c) Viscosity Modifier (d) Flavorants (e) Colorants many types of syrups, especially those prepared commercially, contain special solvents, solubilizing agents, thickeners, or stabilizers.

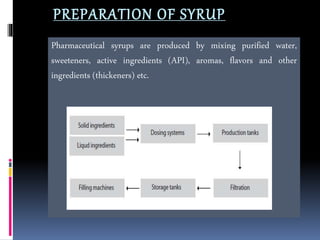

- 8. PREPARATION OF SYRUP Pharmaceutical syrups are produced by mixing purified water, sweeteners, active ingredients (API), aromas, flavors and other ingredients (thickeners) etc.

- 9. There are four methods. Based on the physical and chemical properties on the ingredients, the choice of the method is selected- I. Solution with heat II. Agitation without heat III. Addition of sucrose to liquid medicament IV. Percolation method

- 10. 1. Solution with heat- temperature of purified water is increased to 80 to 85 C taken off from the heat source Then add sucrose and shake it thoroughly Those substances that are heat sensitive and volatile agents are added after the solution attain the room temperature during heating, the sucrose gets hydrolysed, results in the formation of dextrose and fructose these two sugars together called as invert sugar and the process is known as inversion The inversion leads to darkening of the solution

- 11. 2.Agitation without heat- vessel is taken generally made up of stainless steel or glass The vessel should be larger than the desired volume of syrup required Then the ingredients according to the formulation are added to water and mixed It is better to dissolve solid ingredients in the water first and then to add them to syrup This results in easy mixing as sugar solution generally retards mixing

- 12. 3. Addition of sucrose to liquid medicament- This method is generally used for fluid extracts. But those substances which are soluble in alcohol will precipitate out as soon as the addition of water An alternation is to first dissolve all the ingredients in water Now after sometime all the precipitates formed are filtered out Now add sucrose But this method is of no use if the precipitates formed has active ingredients

- 13. 4. Percolation method- the principle of percolation is used A sucrose bed is prepared and then water or vehicle containing therapeutic agent is passed Here the sucrose bed should be coarse and shape of percolator must be cylindrical or cone shapped

- 14. Formulation

- 15. FACTORS TO BE TAKEN INTO CONSIDERATION The manufacturing process must achieve the following factors: • Dissolving of the sugars to form a syrup • Hydration of powdered ingredients • Blending ingredients of widely different viscosity • Suspension or dissolving of active ingredients • The end product must be smooth, agglomerate-free and homogeneous. • Equipment should conform to GMP standards

- 16. Using conventional mixers and agitators for this process leads to several potential problems: • Conventional agitators cannot dissolve high concentrations of sugars at ambient temperature. • Heating of the mixture will be required to aid solution. This is energy inefficient. • The cooling process after this further adds to costs and process time. • Crystallization of the syrup can occur during heating/cooling. • Active ingredients can be damaged by heat. • Thickening ingredients will form agglomerates which conventional equipment cannot disperse

- 17. These problems can be overcome by using a Silverson High Shear mixer. • A Silverson high shear mixer can produce 66% sucrose syrup at ambient temperature. • The heat of dissolution is imparted in the form of shear • Consistent product quality and repeatability is obtained. • An agglomerate free mixture is produced

- 18. Packaging of Syrup Syrup, as a pharmaceutical product requires safe, secure and tamper-proof handling while packaging. Packaging of syrups needs to ensure complete protection from contamination and microbial growth. Our inevitable packaging support assures the safe and secure packaging of syrups so as to ensure their extended shelf life. The general process: ÔÇß Filling ÔÇß Sealing ÔÇß Capping ÔÇß Coding & labeling ÔÇß Wrapping

- 19. Process Involved in Syrup Packaging – Empty Bottles are rinsed though Air-jet cleaning  After complete cleaning, bottles are tested & transferred ahead for filling  Filling machines with their automatic piston fills the bottles with accurate volume of syrup  Capping is done on bottle through capping machines  Plastic or aluminum capsules are bound over the neck of the bottle for secure sealing  Important details regarding packaging date & expiry date are printed on bottles