tariq mahmood new updated CV(1) (1)

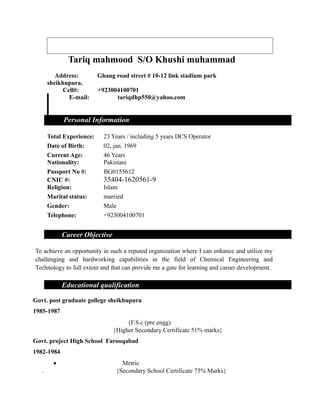

- 1. Tariq mahmood S/O Khushi muhammad Address: Ghang road street # 10-12 link stadium park sheikhupura. Cell#: +923004100701 E-mail: tariqdhp550@yahoo.com Personal Information Total Experience: 23 Years / including 5 years DCS Operator Date of Birth: 02, jan. 1969 Current Age: 46 Years Nationality: Pakistani Passport No #: BG0155612 CNIC #: 35404-1620561-9 Religion: Islam Marital status: married Gender: Male Telephone: +923004100701 Career Objective To achieve an opportunity in such a reputed organization where I can enhance and utilize my challenging and hardworking capabilities in the field of Chemical Engineering and Technology to full extent and that can provide me a gate for learning and career development. Educational qualification Govt. post graduate gollege sheikhupura 1985-1987 (F.S.c (pre engg) {Higher Secondary Certificate 51% marks} Govt. project High School Farooqabad 1982-1984 ŌĆó Metric . {Secondary School Certificate 75% Marks}

- 2. Working experience DH Fertilizers limited Production Department Plant Operator: Since 2 Apr 1988 ├ś Description UTIC Urea Plant {Maintain safe and smooth plant operation at all these section} 1. Synthesis Section. o High Pressure 5 stages PD CO2 Compressors operating pressure 3200 psig. o High pressure Ammonia pumps, URACA Carbamate Recycle pumps o Urea Reactors, Letdown Valves, Motoyama Valves 2. Decomposition and Recovery Section o Liquid Distributor, Medium pressure Decomposer, HPAC o Low pressure Decomposer, Low pressure Absorber o Vacuum concentrator, Distillation column o Ammonia Condensers, Recovered and Feed Ammonia Reservoir o Steam Turbine and Ammonia Supply and Booster pump 3. Prilling Tower o Falling Film Evaporators, Air Heater o Molten Urea Pump, Prilling bucket o Scraper at the hopper of the Prilling Tower o Sieves, conveyers, Uresoft spray and recycling of under and over size Prills DH Fertilizers limited Training Department Trainee Operator : ( 2 Apr 1988 to 15 Oct 1989) ├ś Description: 1. Class room Training four months including o API Pilot o PIDs o TPC 2. On Job Training o Urea Unit Synthesis Section Professional Job Profile

- 3. ┬¦ Day to day activities: Assisting Shift Supervisor in planning Day - To - Day activities in coordination with other trades to execute maintenance activities in safe and environmental friendly way. ┬¦ Quality Control: To enhance product quality follows established quality standards and quality control system. ┬¦ Cost saving & Production Budget: Follows superiorŌĆÖs guidelines for smooth operation to achieve production budget. ┬¦ Identify the corrective measures for process problems and gives suggestion for improvement with cost effectiveness. ┬¦ Team Work & Communication: Excellent communication and clear understanding of process requirement. Apply effective relationship management tool to lead and work with a large team. ┬¦ Quality Management System: Good understanding about occupational health, Safety, Environment & Quality management system. ┬¦ Training: Assists Shift supervisor to train new field operator, Skills and qualification Personal Skills: ŌĆó Good Communication Skills ŌĆó Emergency Handling With great care. ŌĆó Good Trainer For new trainee operator and Engineers. Computer Skills: 1. Good command on MS office 2. Conversant with internet Languages: ŌĆó Urdu: language level (writing , speaking, listening) ŌĆó English: language level ( writing, speaking, listening) Training courses and Workshops ├ś Special Training Industrial Fire Training by Safety Department many times. ├ś Work Permit System. (Cold work, hot work, confined space entry).

- 4. ├ś Emergency handling rehearsals. ├ś Safety meetings, discussions, presentations. ├ś Knowledge to use fire extinguishers i.e. halotron, dry chemical, CO2, BCF. ├ś MSDS of hazards chemicals, fire fighting, fire fighting extinguishers. ├ś Field training on urea (all sections). ├ś DCS training for control room operator. ├ś Process Hazards Analysis (PHA) training. ├ś Accident investigation training. ├ś Management of change (MOC) training. ├ś Du Pont The best safety Practice. ├ś OSHAs Safety Standard ├ś What if Analysis ├ś Take an active part in Process Safety Management ├ś Pre Start up Safety review and job cycle check. Hobbies ŌĆó Plying badminton ŌĆó Reading articles of news paper ŌĆó Reading books Reference ŌĆó Abdul Aziz Unit Manager Urea Unit DH Fertilizer limited Phone: +923018430064 E-mail: aaziz@dawoodgroup.com