Technical Module - PHE

- 2. Plate heat exchangers • The heat transfer surface consists of a number of thin corrugated plates pressed out of a high grade metal. • The pressed pattern on each plate surface induces turbulence and minimizes stagnant areas and fouling. • All plate and frame heat exchangers are made with what may appear to be a limited range of plate designs.

- 3. Performance of Plate Heat Exchanger • Superior thermal performance is the hallmark of plate heat exchangers. • Compared to shell-and-tube units, plate heat exchangers offer overall heat transfer coefficients 3 to 4 times higher. • These values, typically 4000 to 7000 W/m2 °C (clean), result in very compact equipment.

- 4. • This high performance also allows the specification of very small approach temperature (as low as 2 to 3°C) which is sometimes useful in geothermal applications. • This high thermal performance does come at the expense of a somewhat higher pressure drop. • Selection of a plate heat exchanger is a trade-off between U- value (which influences surface area and hence, capital cost) and pressure drop (which influences pump head and hence, operating cost). • Increasing U-value comes at the expense of increasing pressure drop.

- 5. Classification of Plate Heat Exchangers • Gasketed plate heat exchangers • Brazed plate heat exchangers • Welded plate heat exchangers

- 6. Gasketed plate heat exchangers

- 7. The Characteristic Parameter • Thermal length is a dimensionless number that allows the design engineer to relate the performance characteristics of a channel geometry to those of a duty requirement. • Thermal length (Θ) is the relationship between temperature difference ∆T on one fluid side and LMTD. • The thermal length of a channel describes the ability of the channel to affect a temperature change based on the log mean temperature difference (LMTD). LMTD TT outin  

- 8. • The thermal length of a channel is a function of the channel hydraulic diameter, plate length, and the angle of the corrugations, along with the physical properties of the process fluids and available pressure drop. • To properly design a PHE, the thermal length required by the duty must be matched with that achievable by the selected channel geometry.

- 9. A Plate HX is said to be Optimally Sized, if the thermal length required by the duty can match the characteristic of the channel, by utilizing all the available pressure drop with no over- dimensioning, for any chosen channel geometry. Central Idea

- 10. Controlled Designs Thermally Controlled Designs: • If the design exceeds the allowable pressure drop for a given thermal duty. • More plates be added and pressure drop is reduced by lowering the velocity. • Such a design is termed thermally controlled. Hydraulically Controlled Designs: • If the design pressure drop is lower than the allowable pressure drop. • This results in a greater temperature change across the plate than required, or over-dimensioning. • Few plates be removed and pressure drop is increased by increasing the velocity. • Such a design is termed pressure drop controlled.

- 11. An Economic Design • To have the most economical and efficient exchanger it is critical to choose, for each fluid, a channel geometry that matches the thermal length requirement of each fluid. • Since thermal length achievable by a channel depends on the physical properties of the fluid, correction factors must be considered when the fluid’s physical properties differ from those for standard fluid (water

- 12. Design & Analysis of Plate HXs • Unlike tubular heat exchangers for which design data and methods are easily available, a plate heat exchanger design continues to be proprietary in nature. • Manufacturers have developed their own computerized design procedures applicable to the exchangers marketed by them. • Information which was published usually related to only one plate model or was of a generalized nature.

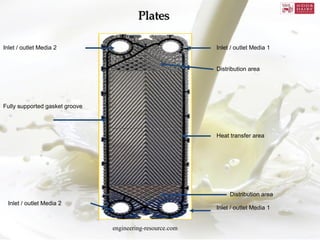

- 13. Plates Distribution area Inlet / outlet Media 1 Heat transfer area Distribution area Inlet / outlet Media 1 Inlet / outlet Media 2 Inlet / outlet Media 2 Fully supported gasket groove engineering-resource.com

- 14. Conventional heat transfer plates and channel combinations.

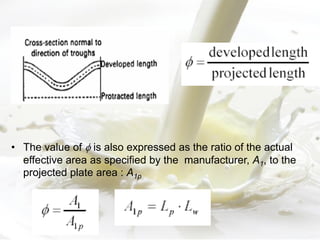

- 15. Plate geometry • Chevron Angle: This important factor, usually termed b, is shown in Figure, the usual range of b being 30°-60° • Effective Plate Length : The corrugations increase the flat or projected plate area, the extent depending on the corrugation pitch and depth. • To express the increase of the developed length, in relation to the projected length, an enlargement factor f is used. • The enlargement factor varies between 1.1 and 1.25, with 1.17 being a typical average.

- 16. • The value of f is also expressed as the ratio of the actual effective area as specified by the manufacturer, A1, to the projected plate area : A1p

- 17. Lp and Lw can be estimated from the port distance Lv and Lh and port diameter Dp as:

- 18. Prepared By: Mukesh Pratap Singh (NDS- DVC) Contacts: Mr. Basant Choudhary: basant.choudhary@nddbdairyservices.com Mr. Mukesh Pratap Singh: mukesh.singh@nddbdairyservices.com

- 19. Thank you