Techniques behind demolition of structures

- 1. TECHNIQUES BEHIND DEMOLITION OF STRUCTURES

- 2. INDEX 1. INTRODUCTION 2. OBJECTIVES 3. STEPS BEFORE DEMOLITION 4. DEMOLITION SEQUENCE 5. METHODS OF DEMOLITION 2

- 3. 1. INTRODUCTION.  In general, demolition can be defined as wrecking or taking out of any load supporting structural element of a building (houses, commercial establishments, and office buildings) or non-building facility (highways, streets, and other non- inhabitable construction projects). 3

- 4. 2. OBJECTIVES.  Old and damaged buildings ( due to earthquake & other various reasons) which are prone to fall down completely or partially must be demolished before any fatal accident.  When the important structural components like beams and columns become absolutely insufficient for service then there is no option other than demolishing the building.  When a new structure need to be constructed on the site the old structure is demolished.  For safety of neighbouring area a deteriorated building is often demolished. 4

- 5. 3. STEPS BEFORE DEMOLITION. a. Surveying. b. Removal of hazardous materials. c. Preparation of plan. d. Safety measures. 5

- 6. SURVEYING The building survey should cover the following: • The construction materials. • The existing use and, if possible, the past uses of the building prior to demolition. • Adjoining pedestrian and vehicular traffic conditions. • The sensitivity of neighbourhood with respect to noise, dust, vibration and traffic impact. • Available site area to allow on-site sorting of building debris. 6

- 7. REMOVAL OF HAZARDOUS MATERIALS: Asbestos Containing Material: • In the case when asbestos containing material are discovered, specialist contractor shall be employed to remove such asbestos containing material. The asbestos waste should be handled, stored and disposed of as chemical waste in accordance with the waste disposal regulation. 7

- 8. Soil Contamination Material: • In the case when possible soil contamination materials is present, specialist shall be employed to prepare soil contamination test proposal and submit such proposal to the environmental protection department for comment. 8

- 9. PREPARATION OF PLAN: • A plan showing location of the building to be demolished, sections of the slopes with ground level contours and detailed topography, ground removal and backfilling, distances of adjacent structures from the building to be demolished. • A layout plan of all floors of the building to be demolished, with adequate sections. • A plan showing the procedure for the demolition of the building. 9

- 10. • A plan showing the proposed shoring and temporary support to be provided to the building to be demolished. • In the case when powered mechanical plants and equipment are used, a plan showing the route of movement of powered mechanical plants and equipments. 10

- 11. SAFETY MEASURES: Training and Communication: • Demolition workers, including plant or equipment operators, shall go through proper job safety training and be informed of the potential hazards by attending training sessions as well as on the – job training. 11

- 12. Equipment Maintenance: • All equipment shall be tested and examined before use. They shall be properly stored and maintained. The equipment shall be inspected daily and results of the inspected daily and results of the inspection shall be recorded accordingly. 12

- 13. Electrical Safety: • A properly connected power source from a local electric utility supplier or a mobile electricity generator shall be utilized in demolition sites. Fire: • All flammable goods shall be removed from site unless they are necessary for works involved. Any remaining flammable goods shall be stored in proper storage facilities. 13

- 14. METHODS OF DEMOLITION A. Ball and crane method. B. Dismantling C. Pneumatic and hydraulic breaker D. Explosives 14

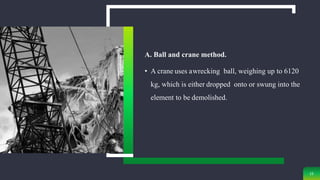

- 15. A. Ball and crane method. • A crane uses awrecking ball, weighing up to 6120 kg, which is either dropped onto or swung into the element to be demolished. 15

- 16. B. Dismantling. • Selective or complete demolition of concrete structures is possible by cutting elements and then removing them with a crane. • The cutting process may be by sawing, water jetting or thermal lance. 16

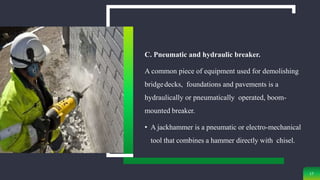

- 17. C. Pneumatic and hydraulic breaker. A common piece of equipment used for demolishing bridgedecks, foundations and pavements is a hydraulically or pneumatically operated, boom- mounted breaker. • A jackhammer is a pneumatic or electro-mechanical tool that combines a hammer directly with chisel. 17

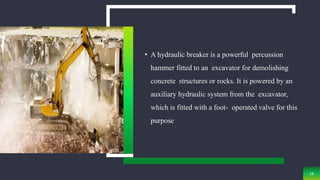

- 18. • A hydraulic breaker is a powerful percussion hammer fitted to an excavator for demolishing concrete structures or rocks. It is powered by an auxiliary hydraulic system from the excavator, which is fitted with a foot- operated valve for this purpose 18

- 19. D. Implosion. • In the controlled demolition industry, building implosion is the strategic placing of explosive material and timing of its detonation so that a structure collapses on itself in a matter of seconds, minimizing the physical damage to its immediate surroundings. 19

- 20. Advantages of explosive demolition. • Less expensive. • No ground vibrations. • Quickest methods. • Suitable for multi-storyed / high piers, cabins, distressed piers etc. 20

- 21. 21

- 22. CONCLUSION • It can be concluded that demolishing/ imploing the building structure will prove very useful, economical and the quickest for reconstruction. • Leads to safe and controlled demolition for the occupants and neighbourhood. • Development in techniques allows a rapid demolition with no harm to the environment. 22

- 23. THANK YOU Add a Footer 23