Tensile

- 2. TENSILE IS A TYPE OF FORCE APPLIED ON A MATERIAL. IT IS A CAPABILITY OF MATERIAL OF BEING STRETCH OUT

- 3. A tensile structure is a construction of elements carrying only tension and no compression or bending. A tensile membrane structure is most often used as a roof, as they can economically and attractively span large distances. Tension roofs or canopies are those in which every part of the structure is loaded only in tension, with no requirement to resist compression or bending forces.

- 5. There are many great advantages and functional benefits of tensile membrane structures and here are few reasons why: Flexible Design Aesthetics - Tensile membrane structures provide virtually unlimited designs of distinctive elegant forms that can be realized because of the unique flexible characteristics of membrane resulting in an iconic and unique structure or feature for any building owner, city or even region. Outstanding Translucency â In daylight, fabric membrane translucency offers soft diffused naturally lit spaces reducing the interior lighting costs while at night, artificial lighting creates an ambient exterior luminescence. Excellent Durability â With several different membranes in the market place such as PTFE fiberglass, ETFE film, PVC, and ePTFE, the durability and longevity of tensile membrane structures have been proven.

- 6. Lightweight Nature - The lightweight nature of membrane is a cost effective solution that requires less structural steel to support the roof compared to conventional building materials, enabling long spans of column-free space. Low Maintenance â Tensile membrane systems are somewhat unique in that they require minimal maintenance when compared to an equivalent-sized conventional building. Cost Benefits â Most tensile membrane structures have high sun reflectivity and low absorption of sunlight, thus resulting in less energy used within a building and ultimately reducing electrical energy costs.

- 7. Types of structures: âĒStayed âĒSuspended âĒ Anticlastic âĒ Pneumatic âĒTrussed

- 8. STAYED: To span railroad trucks underneath, the truss roof is suspended by stay cables.

- 9. SUSPENDED STRUCTURES: GOLDEN GATE BRIDGE.

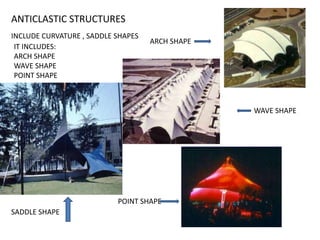

- 10. ANTICLASTIC STRUCTURES INCLUDE CURVATURE , SADDLE SHAPES IT INCLUDES: ARCH SHAPE WAVE SHAPE POINT SHAPE ARCH SHAPE WAVE SHAPE POINT SHAPE SADDLE SHAPE

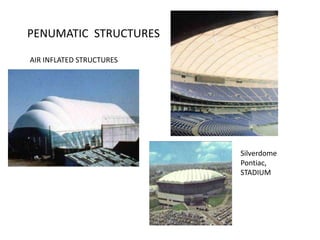

- 11. PENUMATIC STRUCTURES AIR INFLATED STRUCTURES Silverdome Pontiac, STADIUM

- 13. USES OF TENSILE STRUCTURES: âĒUSE AS PENUMATIC SHADE IN STATIDUMS. âĒANTICLASTIC STRUCTURES ARE VERY FREQUENT IN RESORTS PAVILION. âĒIN SHADE OF CAR PARKING. âĒIN SHADE OF OPEN THEATRE. âĒIN SHADE OF SWMING POOL. âĒIN PATIO AWRIGE.

- 14. MATERIAL FOR TENSILE MEMBRANE: Structural Fabric Structural fabric is the material that defines lightweight tensile structures. Requirements As a primary structural element, it must have the strength to span between supporting elements, carry snow and wind loads, and be safe to walk on. As enclosure element, it needs to be airtight, waterproof, fire resistant and durable. As daily use element, it requires to transmit daylight, reflect heat, control sound, and be easy to keep clean. Sample Materials Fiberglass, Polyester Cloth, PVC, Teflon.

- 15. Polester tensile roof TEFLON COATED FIBER GLASS ROOF

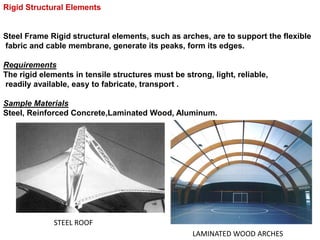

- 16. Rigid Structural Elements Steel Frame Rigid structural elements, such as arches, are to support the flexible fabric and cable membrane, generate its peaks, form its edges. Requirements The rigid elements in tensile structures must be strong, light, reliable, readily available, easy to fabricate, transport . Sample Materials Steel, Reinforced Concrete,Laminated Wood, Aluminum. STEEL ROOF LAMINATED WOOD ARCHES

- 17. CONCRETE ROOF

- 18. Cables Cables serve a number of functions in tensile structure applications: reinforcement of the fabric where the spans and stresses get too large; linear tension support elements along edges; tie-backs and stays to stabilize rigid support element. Requirements The cables need to be light, high-strength and flexible to some extent. Sample Materials High Strength Bridge Strand, Steel, Glass Fiber.

- 19. High-strength Steel CablE GRID SHOWS THE BASE OF CABLE IN STRUCTURES

- 20. DISADVANTAGES : âĒNO RIGIDITY. âĒLOSS OF TENSION IS DANGEROUS FOR STABILITY. ADVANTAGES: âĒUNIQUE DESIGNS. âĒLIGHTWEIGHT âĒFLEXIBLE âĒENVIRONMENTALLY SENSITIVE ADVANTAGES FABRIC TENSILE STRUCTURE

- 21. ADVANTAGES FABRIC TENSILE STRUCTURE One of the main advantages of fabric structure is that you can install it rapidly and easily. Tension fabric buildings provide abundant daytime lighting that is bright and natural, the interior of a fabric structure is an inviting environment that people, plants and animals thrive in. Fabric buildings are Acoustics exceptional; no sounds of pelting rain. Fabric buildings have Low cost per square foot, Initial investment is low. Fabric buildings are self cleaning; never needs painting; dust, dirt, pollutants wash off with Water no rotting parts to replace. Fabric structures are durable, corrosion resistance. salt, fertilizer and other corrosive materials have virtually no effect on polyethylene fabric. Flexibility, when a large clearspan building with tall overhead clearances is needed, a fabric structure is an economical solution.