textiles.ppt

- 1. The Industrial Revolution Changes in the Textile Industry

- 2. The Domestic System • Before the Industrial Revolution, the production of Woollen Cloth was Britain’s most important manufacturing industry • Cloth making was centred in areas where sheep farming was common: Yorkshire, the Cotswolds, Devon … • The main processes – carding, spinning and weaving were carried out in the cottages of workers • This was known as the Carding Spinning Weaving

- 3. How did the Domestic System work? • A merchant delivered wool to the workers’ homes • Children carded (untangled) the wool • Women and girls spun the wool into yarn using a spinning wheel • Men wove the yarn into cloth on a loom • The merchant took the cloth to other workers for stretching, dyeing, and cropping

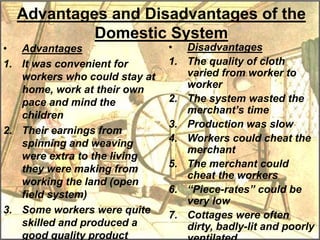

- 4. Advantages and Disadvantages of the Domestic System • Advantages 1. It was convenient for workers who could stay at home, work at their own pace and mind the children 2. Their earnings from spinning and weaving were extra to the living they were making from working the land (open field system) 3. Some workers were quite skilled and produced a good quality product • Disadvantages 1. The quality of cloth varied from worker to worker 2. The system wasted the merchant’s time 3. Production was slow 4. Workers could cheat the merchant 5. The merchant could cheat the workers 6. “Piece-rates” could be very low 7. Cottages were often dirty, badly-lit and poorly

- 5. Why was there a Revolution in the textile industry? • The population was growing rapidly • There was an increase in the demand for better quality cloth • The price of raw cotton fell as more was imported from the slave plantations of USA (after 1776) • New machines were invented which speeded up the working of cotton

- 6. New Technology • Spinning • 1764 James Hargreaves invented “Spinning Jenny” • 1769 Sir Richard Arkwright invented “Water Frame” • 1779 Samuel Crompton invented “Spinning Mule” (so-called because it combined the best of the Jenny and the Frame) – became the most • Weaving • 1733 John Kay invented “Flying Shuttle” • 1785 Edmund Cartwright invented “Power •Hand power •Water power – leads to building of first mills or “Factories” •James Watt’s Steam Engine- form 1770s…

- 7. James Hargreaves and the Spinning Jenny 1764 • This was the first of the new spinning machines • The first models produced thread on 8 spindles at once (instead of 1) • Probably called “Jenny” meaning “Gin”,or “Ginny” short for engine (not after his wife!) • Angry spinners smashed up Hargreaves’ home in Blackburn • Designed for use in domestic system

- 8. Sir Richard Arkwright 1732- 92 • One of the great entrepreneurs of the Industrial Revolution • His “Water Frame”was the first machine to be designed as a “factory” machine – driven by water power • The “Factory Age” began with Arkwright’s mill at Cromford, Derbyshire • He devised the “Factory System” • Employed thousands of workers • Patented his machine • Made a huge fortune

- 9. The Factory System • Other entrepreneurs were quick to copy Arkwright’s system • Many spinning factories were built • For a while weaving remained a domestic craft • The wages of hand loom weavers soared as great quantities of spun yarn were produced • However, by the 1820s Power Looms were being introduced and weavers

- 10. The Luddites • Many skilled craftsmen lost out to the new machines • The first“Luddites” were croppers in Yorkshire • They formed a secret society and smashed machines • The mill owners and the government reacted strongly • Britain was at war with France • Luddites were captured by use of spies • Several machine-breakers were hanged,

- 11. The Importance of Manchester (and Southern Lancashire) • Manchester and Southern Lancashire became the main location for the Cotton Industry because:- 1. The climate was damp – ideal for working cotton 2. It was close to the port of Liverpool – the main port for trade with the USA and imports of raw cotton 3. There were skilled spinners and weavers just across the Pennines in the Yorkshire woollen industry 4. The Pennines supplied fast-flowing streams

- 12. Conclusions • The development of the Factory System massively increased the amount of cotton cloth produced • A new class of “entrepreneurs” made great fortunes • Towns and cities grew up around the new factories – the process of “Urbanisation”- living conditions and public health worsened • Working conditions were very different in the factories to the old Domestic System