The importance of work right

- 1. The Importance of the Alignment. Check your Shoe Construction Before send to Production and think about future problems ŌĆ”Make better, Make Right First Time !!!

- 2. 2 The Last The importance of centralize is must to an perfect fitting !

- 3. 3 The Last Bottom Paper (LBP) Some rules exist to Shoe Factories find a better way to standardize your productions, here you can see the must used system. The result of the LBP (last bottom paper) must be connected with the center of the last, like showed in page 2.

- 4. 4 The Strobel The Strobel should born always from the LBP and must continuous with the same alignment, because everything is connected and will be must important in all process in the Shoe Production.

- 5. 5 Strobel crooked as per LBP What will happened if my Strobel (White color) is like this compared with the LBP (Blue color) ???

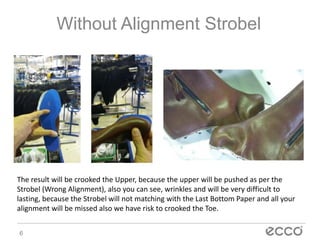

- 6. 6 Without Alignment Strobel The result will be crooked the Upper, because the upper will be pushed as per the Strobel (Wrong Alignment), also you can see, wrinkles and will be very difficult to lasting, because the Strobel will not matching with the Last Bottom Paper and all your alignment will be missed also we have risk to crooked the Toe.

- 7. 7 Strobel as per LBP and molded as per Last Bottom Curve How beautiful and easy will be our Production lines if we do in the right way ŌĆ”. The lasting process will increase output, less work with repair and better quality in finishing area.