The Kanban System applied to Services

- 2. João Paulo Pinto, ISMAI Christiane Lucas Tschaf, CLT

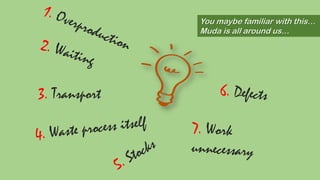

- 5. You maybe familiar with this Muda is all around us 3. Transport

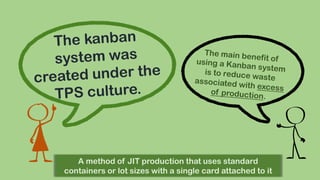

- 7. A method of JIT production that uses standard containers or lot sizes with a single card attached to it

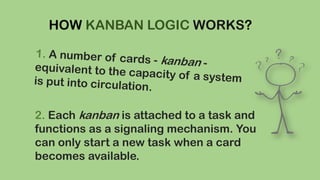

- 8. HOW KANBAN LOGIC WORKS? 2. Each kanban is attached to a task and functions as a signaling mechanism. You can only start a new task when a card becomes available.

- 10. The KANBAN LOGIC promotes the pull system and the continuous flow.

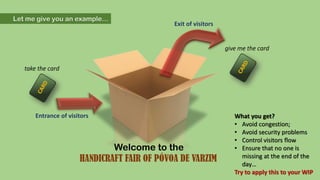

- 11. Let me give you an exampleÔǪ Exit of visitors give me the card take the card Entrance of visitors Welcome to the HANDICRAFT FAIR OF P├ôVOA DE VARZIM What you get? ÔÇó Avoid congestion; ÔÇó Avoid security problems ÔÇó Control visitors flow ÔÇó Ensure that no one is missing at the end of the dayÔǪ Try to apply this to your WIP

- 12. One of the Lean principles implies working within the pull system; ie, producing according of the final customer orders. Rather than working "pushing" tasks along the value chain.

- 14. 2. It is possible to work with the current state of the process, not requiring previous or sudden changes.

- 16. 7. Kanban allows to control WIP and reduce lead time and costs. Remember the LittleÔÇÖs Law: L = W.´ü¼

- 18. Thank you for your attention João Paulo Pinto, PhD MSc(Eng) INSTITUTO SUPERIOR DA MAIA jpinto@ismai.pt Christiane Lucas Tscharf COMUNIDADE LEAN THINKING research@cltservices.net This document is available here: www.slideshare.net/Comunidade_Lean_Thinking