Thermal screw conveyor

- 1. Cooling/Heating Screw Conveyors Sample Industries ? BioMass ? BioFuels ? Foods ? Dairy ? Paper and pulp ? Minerals ? Chemical ? Petrochemical ˇ and many more Sample Processes ? Drying ? Polymerization ? Heat curing ? Cooling/freezing ? Microbial kill ? Sintering/calcining ? Dewatering Testing Available! Rental Unit Available! S. Howes. Inc. For more information Phone: (716) 934-2611 contact one of our Sales Engineers Toll Free: (888) 255-2611 sales@showes.com Fax: (716) 934-2081 www.showes.com ? 2009 S. Howes, Inc., All rights reserved

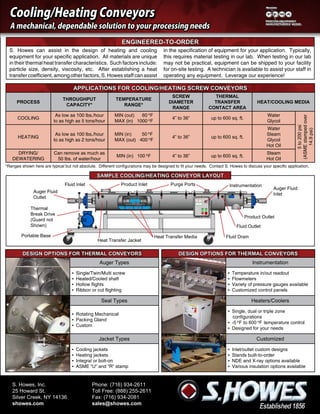

- 2. Cooling/Heating Conveyors A mechanical, dependable solution to your processing needs ENGINEERED-TO-ORDER S. Howes can assist in the design of heating and cooling in the specification of equipment for your application. Typically, equipment for your specific application. All materials are unique this requires material testing in our lab. When testing in our lab in their thermal heat transfer characteristics. Such factors include: may not be practical, equipment can be shipped to your facility particle size, density, viscosity, etc. After establishing a heat for on-site testing. A technician is available to assist your staff in transfer coefficient, among other factors, S. Howes staff can assist operating any equipment. Leverage our experience! APPLICATIONS FOR COOLING/HEATING SCREW CONVEYORS SCREW THERMAL THROUGHPUT TEMPERATURE PROCESS DIAMETER TRANSFER HEAT/COOLING MEDIA CAPACITY* RANGE* RANGE CONTACT AREA As low as 100 lbs./hour MIN (out) 60 o F Water (ASME stamped over COOLING 4ˇ± to 36ˇ± up to 600 sq. ft. to as high as 5 tons/hour MAX (in) 1000 o F Glycol 5 to 200 psi Water 14.9 psi) As low as 100 lbs./hour MIN (in) 50 o F Steam HEATING 4ˇ± to 36ˇ± up to 600 sq. ft. to as high as 2 tons/hour MAX (out) 400 o F Glycol Hot Oil DRYING/ Can remove as much as Steam MIN (in) 100 o F 4ˇ± to 36ˇ± up to 600 sq. ft. DEWATERING 50 lbs. of water/hour Hot Oil *Ranges shown here are typical but not absolute. Different configurations may be designed to fit your needs. Contact S. Howes to discuss your specific application. SAMPLE COOLING/HEATING CONVEYOR LAYOUT Fluid Inlet Product Inlet Purge Ports Instrumentation Auger Fluid Auger Fluid Inlet Outlet Thermal Break Drive Product Outlet (Guard not Shown) Fluid Outlet Portable Base Heat Transfer Media Fluid Drain Heat Transfer Jacket DESIGN OPTIONS FOR THERMAL CONVEYORS DESIGN OPTIONS FOR THERMAL CONVEYORS Auger Types Instrumentation ? Single/Twin/Multi screw ? Temperature in/out readout ? Heated/Cooled shaft ? Flowmeters ? Hollow flights ? Variety of pressure gauges available ? Ribbon or cut flighting ? Customized control panels Seal Types Heaters/Coolers ? Single, dual or triple zone ? Rotating Mechanical configurations ? Packing Gland ? -5 o F to 600 o F temperature control ? Custom ? Designed for your needs Jacket Types Customized ? Cooling jackets ? Inlet/outlet custom designs ? Heating jackets ? Stands built-to-order ? Integral or bolt-on ? NDE and X-ray options available ? ASME ˇ°Uˇ± and ˇ°Rˇ± stamp ? Various insulation options available S. Howes, Inc. Phone: (716) 934-2611 25 Howard St. Toll Free: (888) 255-2611 Silver Creek, NY 14136 Fax: (716) 934-2081 showes.com sales@showes.com