Thermal Validation Equipment Rental

Download as PPTX, PDF0 likes537 views

Thermal Validation Equipment rental for Autoclave Validation, Freeze Drier Validation, Temperature and Humidity mapping. Including Kaye Validator 2000, Ellab Tracksense Pro and Vaisala Dataloggers.

1 of 9

Download to read offline

Recommended

Superheat in Porous Load Autoclaves

Superheat in Porous Load AutoclavesChris Maughan

╠²

This presentation looks at superheat in porous load autoclaves. It explains what superheat is, why superheat is a problem and identifies the causes superheat.║▌║▌▀Ż share porous load autoclave wet loads

║▌║▌▀Ż share porous load autoclave wet loadsChris Maughan

╠²

If you are seeing wet loads in your autoclave we can help, this presentation helps show what a wet load is and why its important. It also includes some of the potential root causes of wet loads.Bowie Dick Tests - Failure Modes and Specification

Bowie Dick Tests - Failure Modes and SpecificationChris Maughan

╠²

The document provides information on Bowie Dick tests used to detect air in steam sterilization autoclaves. It describes how paper and electronic Bowie Dick tests work, potential causes of test failures, and specifications from ISO 11140. Paper tests use chemical indicators that change color with sufficient steam exposure, while electronic tests provide pass/fail results from temperature and pressure sensors. Failures may be due to issues with steam distribution, quality, or autoclave leaks and performance. ISO 11140 provides standards for Bowie Dick test pack configuration and performance.The Ultimate Electronic Bowie Dick Test from Ellab

The Ultimate Electronic Bowie Dick Test from EllabSt├®phane Guillaud

╠²

SteriSense is a brand new and innovative device for

Electronic Bowie Dick Tests that is unmatched in

accuracy, performance and reliability. ISO 11140-4

Compliant6 CLASSES OF CHEMICAL INDICATORS FOR STEAM STERILIZATION

6 CLASSES OF CHEMICAL INDICATORS FOR STEAM STERILIZATIONaccessamg

╠²

Chemical indicators for autoclaves and steam sterilizers play a critical role in sterility assurance programs. There are many types of chemical indicators, such as bowie dick test packs and chemical indicator strips.

All chemical indicators are designed to respond to physical conditions inside the sterilizing chamber. This validates that an autoclave or steam sterilizer is working properly. It also verifies that it met the conditions for sterilization to occur.Airqual 1 breathing air quality test kit datasheet 0

Airqual 1 breathing air quality test kit datasheet 0a1-cbiss

╠²

The AIRQUAL-1 is a portable air quality test kit that allows for on-site testing of compressed air. It can instantly test for levels of carbon monoxide, carbon dioxide, oxygen, and oil/mist contamination in less than 5 minutes without requiring additional equipment or power. The lightweight and self-contained AIRQUAL-1 kit ensures full compliance with air quality standards and provides accurate, real-time readings for a variety of industrial applications including offshore oil rigs.Validation of sterelization_equipment

Validation of sterelization_equipmentMalla Reddy College of Pharmacy

╠²

This document discusses the validation of sterilization equipment, including dry heat sterilizers and steam sterilizers. It provides definitions of key terms like sterilization and depyrogenation. It also outlines the process for validating different types of sterilization equipment, including design qualification, installation qualification, operational qualification, and performance qualification. The validation process involves tests to evaluate temperature distribution, heat penetration, and lethalities to verify sufficient sterilization is achieved. validation process

validation processlaraib jameel

╠²

Validation of sterilization processes involves establishing that a specific sterilization method will consistently produce sterile products meeting quality standards. This document discusses various sterilization methods and their validation. It describes validating steam, dry heat, and gaseous sterilization processes. Validation studies determine heat distribution, penetration, and mechanical reliability to identify cold spots and ensure sterilization effectiveness. Biological and endotoxin challenges are also important to demonstrate destruction of microorganisms and toxins.Validation of dry heat sterilization

Validation of dry heat sterilizationDeepak Shanbhag

╠²

Validation is the process of checking of the process, equipment and method whereas qualification is solely done for equipment and qualification of instrument helps in quality of pharmaceutical product.COOLMEAT_Campden Seminar_Presentation

COOLMEAT_Campden Seminar_PresentationLee Gapper

╠²

The COOLMEAT project aimed to develop an alternative rapid cooling method for cooked meat that improved food safety and quality compared to conventional vacuum cooling. Testing showed the immersion vacuum cooling (IVC) prototype reduced cooling times by 40-70% compared to air blast cooling and had lower weight losses than vacuum cooling alone. Sensory analysis found IVC produced meat with comparable texture, tenderness and juiciness to traditionally cooled meat. IVC is a more affordable and effective cooling method that allows meat processors to meet EU regulatory guidelines.validation of Sterilization process

validation of Sterilization processlaraib jameel

╠²

Validation of sterilization processes is important to establish that a specific sterilization method will consistently produce sterile products meeting quality standards. This document discusses various sterilization methods and their validation. It describes validating steam, dry heat, and gaseous sterilization processes. The key aspects covered for each method include qualification of equipment, calibration of temperature monitoring devices, heat distribution and penetration studies, and biological indicators to demonstrate sterility assurance.steam sterilization validation

steam sterilization validation motasim abdelrahman

╠²

This document discusses validation of steam sterilization processes. It provides information on key terms used in microbial death kinetics like D values, Z values, and F values. It presents formulas used to calculate these values. The document also discusses autoclave calibration methods, including using boiling water and multipoint calibration. An example standard operating procedure for autoclave calibration is given. Common problems with steam sterilization validation are listed.validation of autoclave

validation of autoclavekarthik Bangaru

╠²

The document describes the operation and validation of an industrial double door autoclave. It provides details on the various sterilization cycles used - vacuum leak test, Bowie-Dick test, steam in process test, gravity cycle, and high pressure high vacuum cycle. The procedures, parameters, and results of running these cycles to validate the autoclave are presented. The conclusion is that the autoclave satisfies all United States Pharmacopeia parameters and can be used for sterilization.Temperature calibration

Temperature calibrationChetan Yadav

╠²

Microprocessor-controlled digital pressure gauges that combine precision and functionality in a compact, robust and simple-to-use package.Autoclave

AutoclaveKhushboo Pasbola

╠²

Steam sterilization uses high-pressure steam to kill microorganisms. It is the most effective sterilization method when heat and moisture do not damage products. An autoclave uses steam to heat items inside a pressurized chamber, reaching temperatures over 121┬░C. Validation of a sterilization process involves qualification of the autoclave design, installation, operation, and performance through studies measuring temperature distribution, heat penetration, and using biological indicators to confirm a sterilization log reduction factor is achieved.AIRQUAL-1 breathing air quality test kit

AIRQUAL-1 breathing air quality test kitAymeric Beaupied

╠²

This comprehensive breathing air quality test kit is compact, easy to operate and can be used to indicate the level of contamination, as well as, operating flow, temperature and pressure. Sampling of compressed air is fast, with the ability to process results in less than minutes. Concentrations of carbon monoxide, carbon dioxide, oxygen and oil & mist can be determined almost instantly without further lab analysis.

With everything you need contained in one convenient, lightweight aluminium case and with no power source required, the AIRQUAL-1 is suitable for a variety of applications including; offshore oil rigs and on-site visits. In addition to the detection of the compressed air contaminants listed, AIRQUAL-1 also features an oxygen analyser allowing for constant real-time display of the oxygen content within the compressed air systemWater-Gas-Shift Reactor Loading & Unloading Considerations

Water-Gas-Shift Reactor Loading & Unloading ConsiderationsGerard B. Hawkins

╠²

(WGS) Water Gas Shift - Loading & Unloading

High Temperature Shift & Low Temperature Shift

Fixed Beds: Catalyst Discharge

Data sheet g52 m print version

Data sheet g52 m print versiona1-cbiss

╠²

The Graphite 52M is a heated FID volatile organic compounds analyzer that allows for continuous and accurate total VOC monitoring. It features a heated detector block up to 191┬░C that eliminates condensation and allows for measurement of heavy hydrocarbons. The compact device has a fast response time and is fully supported by certified data acquisition software. It is suitable for applications such as waste incineration monitoring in compliance with relevant standards and directives.Oil burner servicing, combustion efficiency testing cbt 2

Oil burner servicing, combustion efficiency testing cbt 2dbartley123

╠²

This document provides information on combustion efficiency testing for oil burners. It discusses measuring draft, smoke, CO2 levels, stack and net temperatures, and using these measurements to calculate efficiency. Safety precautions are highlighted for each test. The purpose of combustion testing is to evaluate how well the unit is using fuel and should be done annually with routine service. Key steps include measuring draft, using a smoke tester to check for smoke, measuring CO2 levels with a shaker bottle, and calculating net temperature and efficiency.Valve Emissions Testing Webinar

Valve Emissions Testing WebinarA.W.Chesterton

╠²

The document summarizes information from an emissions testing webinar presented by Gregory Cole, Luke Norton, and Cameron Rapoport on February 12th, 2016. It discusses various standards and regulations for emissions testing of valves, including API 622, API 624, ISO 15848-1, and TA-Luft. The standards describe test procedures, parameters, leakage classes and allowances to qualify different types and sizes of valves. Future revisions to standards aim to reduce allowable leakage levels and eliminate re-torques.Quality Control & warehousing

Quality Control & warehousing carlfglobal

╠²

The document describes quality control and warehousing procedures. It includes flow charts showing the inspection process for materials from suppliers through various production stages to final packaging. Samples are sent to certified labs for chemical testing. Materials are inspected according to checklists and drawings before final packaging or being sent back. Standards used include Danish, ASTM, and AISI. Quality norms specify dimensions, fitment, finishing, and materials. Warehousing involves batch numbering, first in first out storage, packing materials, segregated and labeled storage, and labeling equipment.Presentation of industrial pharmacy 2

Presentation of industrial pharmacy 2Malla Reddy College of Pharmacy

╠²

The document discusses the validation of various sterilization methods and water supply systems used in pharmaceutical manufacturing. It provides details on:

1. The key properties of sterile products and various sterilization methods like heat, gas, radiation.

2. The validation process for steam, dry heat and ethylene oxide sterilization including qualification of equipment and instruments, heat distribution studies, biological indicators, and establishing a monitoring program.

3. Types of water systems used, water treatment techniques, equipment components, design considerations for storage and distribution, and the concept of validation involving engineering design, operating procedures, maintenance and testing under all conditions.Furnace calibration - temperature uniformity survey

Furnace calibration - temperature uniformity surveyTempsens Instruments

╠²

The document discusses furnace calibration requirements according to the AMS 2750E aerospace standard. It describes the need for temperature uniformity surveys (TUS) to determine a furnace's work zone and ensure uniform heating. TUS involves measuring temperature variations across a furnace using thermocouples and comparing results to the standard's allowable deviations. The document also covers furnace classes and their uniformity requirements, sensor requirements, how to conduct a TUS, and the related system accuracy test (SAT) to determine temperature control errors.Overall Quality Testing Methods and Analysis

Overall Quality Testing Methods and AnalysisMitul Tewar

╠²

This document outlines quality testing methods and analysis used at an IBJ quality control laboratory. It discusses the importance of quality control in maintaining product quality and preventing defects. It describes different types of samples that are tested, including water, gas, CS2, sulfur, and MDEA samples. Test parameters for each sample type are provided. Specifications for test results are given for various samples, such as pH and chloride levels for water samples and H2S content for gas samples. Reference standards and safety precautions are also discussed.Calibration

CalibrationPrashant thakur

╠²

this PPT will help u with understanding what is calibration, and calibration procedure for calibrating temperature measuring devicesCryogenic testing system

Cryogenic testing systemsangeetha baskaran

╠²

This document discusses cryogenic testing capabilities for valves. It defines cryogenic temperatures as below -180┬░C/-240┬░F, where most gases liquefy. Valves are tested at these low temperatures to ensure proper functioning under extreme environmental conditions. The described cryogenic testing facility can test valves up to 56" in size from -196┬░C to ambient, under pressures up to 200 bar, using test standards to verify performance, leakage, and cycle times at cryogenic conditions. This helps assure safety and minimize issues during plant start-up.Sodium Analyzer for Industrial Applications

Sodium Analyzer for Industrial ApplicationsClassic Controls, Inc.

╠²

Meet the demanding needs of high-purity water measurements and high-acid cation exchange applications with the Thermo ScientificŌäó OrionŌäó 2111XP Sodium Analyzer. This system offers unmatched reliability in analyzing critical sample streams throughout the power/steam generation and industrial water industry. It is an all-in-one system from one of the most trusted names in sodium monitoring.Reformer Tube Inspection & Issues Affecting Tube Life

Reformer Tube Inspection & Issues Affecting Tube LifeThomas Fortinberry

╠²

This document discusses reformer tube inspection tools and issues affecting tube life. It describes an internal and external inspection system that uses laser scanning and eddy current testing to detect cracks, measure diameter expansion, and monitor creep damage in reformer tubes. Local issues like overheating, thermal shocks, and catalyst fouling can be identified. Comprehensive inspection reports are generated with results for each tube. The non-destructive testing helps assess tube condition and remaining life.Calibration

Calibrationsgmlab360

╠²

SGM calibration laboratory provides calibration services for a wide range of thermal, mechanical, and electrical instruments to ensure high accuracy and low measurement uncertainty. They maintain strict environmental conditions and use experienced engineers to calibrate instruments at their state-of-the-art facility or at customer sites. The calibration services include recalibration of temperature, pressure, and electrical signals in instruments such as ovens, humidity chambers, balances, meters, and sensors.Calibration introduction

Calibration introductionsigmatest21

╠²

MECHANICAL -Pressure, Mass, Volume, Torque, Sound, Force, Hardness

ELECTRO-TECHNICAL -AC/DC Voltage, AC/DC Current, Resistance, LCR, Frequency, Power Factor, Temperature Simulation

THERMAL -Temperature (-80 C to 1200 C), Humidity

These all are our specialties in Sigma Test & Research Centre Calibration's lab(link this word to http://www.sigmatest.org/calibration.html). Kindly visit our web page also for more clarity on the calibration topic.

More Related Content

What's hot (20)

Validation of dry heat sterilization

Validation of dry heat sterilizationDeepak Shanbhag

╠²

Validation is the process of checking of the process, equipment and method whereas qualification is solely done for equipment and qualification of instrument helps in quality of pharmaceutical product.COOLMEAT_Campden Seminar_Presentation

COOLMEAT_Campden Seminar_PresentationLee Gapper

╠²

The COOLMEAT project aimed to develop an alternative rapid cooling method for cooked meat that improved food safety and quality compared to conventional vacuum cooling. Testing showed the immersion vacuum cooling (IVC) prototype reduced cooling times by 40-70% compared to air blast cooling and had lower weight losses than vacuum cooling alone. Sensory analysis found IVC produced meat with comparable texture, tenderness and juiciness to traditionally cooled meat. IVC is a more affordable and effective cooling method that allows meat processors to meet EU regulatory guidelines.validation of Sterilization process

validation of Sterilization processlaraib jameel

╠²

Validation of sterilization processes is important to establish that a specific sterilization method will consistently produce sterile products meeting quality standards. This document discusses various sterilization methods and their validation. It describes validating steam, dry heat, and gaseous sterilization processes. The key aspects covered for each method include qualification of equipment, calibration of temperature monitoring devices, heat distribution and penetration studies, and biological indicators to demonstrate sterility assurance.steam sterilization validation

steam sterilization validation motasim abdelrahman

╠²

This document discusses validation of steam sterilization processes. It provides information on key terms used in microbial death kinetics like D values, Z values, and F values. It presents formulas used to calculate these values. The document also discusses autoclave calibration methods, including using boiling water and multipoint calibration. An example standard operating procedure for autoclave calibration is given. Common problems with steam sterilization validation are listed.validation of autoclave

validation of autoclavekarthik Bangaru

╠²

The document describes the operation and validation of an industrial double door autoclave. It provides details on the various sterilization cycles used - vacuum leak test, Bowie-Dick test, steam in process test, gravity cycle, and high pressure high vacuum cycle. The procedures, parameters, and results of running these cycles to validate the autoclave are presented. The conclusion is that the autoclave satisfies all United States Pharmacopeia parameters and can be used for sterilization.Temperature calibration

Temperature calibrationChetan Yadav

╠²

Microprocessor-controlled digital pressure gauges that combine precision and functionality in a compact, robust and simple-to-use package.Autoclave

AutoclaveKhushboo Pasbola

╠²

Steam sterilization uses high-pressure steam to kill microorganisms. It is the most effective sterilization method when heat and moisture do not damage products. An autoclave uses steam to heat items inside a pressurized chamber, reaching temperatures over 121┬░C. Validation of a sterilization process involves qualification of the autoclave design, installation, operation, and performance through studies measuring temperature distribution, heat penetration, and using biological indicators to confirm a sterilization log reduction factor is achieved.AIRQUAL-1 breathing air quality test kit

AIRQUAL-1 breathing air quality test kitAymeric Beaupied

╠²

This comprehensive breathing air quality test kit is compact, easy to operate and can be used to indicate the level of contamination, as well as, operating flow, temperature and pressure. Sampling of compressed air is fast, with the ability to process results in less than minutes. Concentrations of carbon monoxide, carbon dioxide, oxygen and oil & mist can be determined almost instantly without further lab analysis.

With everything you need contained in one convenient, lightweight aluminium case and with no power source required, the AIRQUAL-1 is suitable for a variety of applications including; offshore oil rigs and on-site visits. In addition to the detection of the compressed air contaminants listed, AIRQUAL-1 also features an oxygen analyser allowing for constant real-time display of the oxygen content within the compressed air systemWater-Gas-Shift Reactor Loading & Unloading Considerations

Water-Gas-Shift Reactor Loading & Unloading ConsiderationsGerard B. Hawkins

╠²

(WGS) Water Gas Shift - Loading & Unloading

High Temperature Shift & Low Temperature Shift

Fixed Beds: Catalyst Discharge

Data sheet g52 m print version

Data sheet g52 m print versiona1-cbiss

╠²

The Graphite 52M is a heated FID volatile organic compounds analyzer that allows for continuous and accurate total VOC monitoring. It features a heated detector block up to 191┬░C that eliminates condensation and allows for measurement of heavy hydrocarbons. The compact device has a fast response time and is fully supported by certified data acquisition software. It is suitable for applications such as waste incineration monitoring in compliance with relevant standards and directives.Oil burner servicing, combustion efficiency testing cbt 2

Oil burner servicing, combustion efficiency testing cbt 2dbartley123

╠²

This document provides information on combustion efficiency testing for oil burners. It discusses measuring draft, smoke, CO2 levels, stack and net temperatures, and using these measurements to calculate efficiency. Safety precautions are highlighted for each test. The purpose of combustion testing is to evaluate how well the unit is using fuel and should be done annually with routine service. Key steps include measuring draft, using a smoke tester to check for smoke, measuring CO2 levels with a shaker bottle, and calculating net temperature and efficiency.Valve Emissions Testing Webinar

Valve Emissions Testing WebinarA.W.Chesterton

╠²

The document summarizes information from an emissions testing webinar presented by Gregory Cole, Luke Norton, and Cameron Rapoport on February 12th, 2016. It discusses various standards and regulations for emissions testing of valves, including API 622, API 624, ISO 15848-1, and TA-Luft. The standards describe test procedures, parameters, leakage classes and allowances to qualify different types and sizes of valves. Future revisions to standards aim to reduce allowable leakage levels and eliminate re-torques.Quality Control & warehousing

Quality Control & warehousing carlfglobal

╠²

The document describes quality control and warehousing procedures. It includes flow charts showing the inspection process for materials from suppliers through various production stages to final packaging. Samples are sent to certified labs for chemical testing. Materials are inspected according to checklists and drawings before final packaging or being sent back. Standards used include Danish, ASTM, and AISI. Quality norms specify dimensions, fitment, finishing, and materials. Warehousing involves batch numbering, first in first out storage, packing materials, segregated and labeled storage, and labeling equipment.Presentation of industrial pharmacy 2

Presentation of industrial pharmacy 2Malla Reddy College of Pharmacy

╠²

The document discusses the validation of various sterilization methods and water supply systems used in pharmaceutical manufacturing. It provides details on:

1. The key properties of sterile products and various sterilization methods like heat, gas, radiation.

2. The validation process for steam, dry heat and ethylene oxide sterilization including qualification of equipment and instruments, heat distribution studies, biological indicators, and establishing a monitoring program.

3. Types of water systems used, water treatment techniques, equipment components, design considerations for storage and distribution, and the concept of validation involving engineering design, operating procedures, maintenance and testing under all conditions.Furnace calibration - temperature uniformity survey

Furnace calibration - temperature uniformity surveyTempsens Instruments

╠²

The document discusses furnace calibration requirements according to the AMS 2750E aerospace standard. It describes the need for temperature uniformity surveys (TUS) to determine a furnace's work zone and ensure uniform heating. TUS involves measuring temperature variations across a furnace using thermocouples and comparing results to the standard's allowable deviations. The document also covers furnace classes and their uniformity requirements, sensor requirements, how to conduct a TUS, and the related system accuracy test (SAT) to determine temperature control errors.Overall Quality Testing Methods and Analysis

Overall Quality Testing Methods and AnalysisMitul Tewar

╠²

This document outlines quality testing methods and analysis used at an IBJ quality control laboratory. It discusses the importance of quality control in maintaining product quality and preventing defects. It describes different types of samples that are tested, including water, gas, CS2, sulfur, and MDEA samples. Test parameters for each sample type are provided. Specifications for test results are given for various samples, such as pH and chloride levels for water samples and H2S content for gas samples. Reference standards and safety precautions are also discussed.Calibration

CalibrationPrashant thakur

╠²

this PPT will help u with understanding what is calibration, and calibration procedure for calibrating temperature measuring devicesCryogenic testing system

Cryogenic testing systemsangeetha baskaran

╠²

This document discusses cryogenic testing capabilities for valves. It defines cryogenic temperatures as below -180┬░C/-240┬░F, where most gases liquefy. Valves are tested at these low temperatures to ensure proper functioning under extreme environmental conditions. The described cryogenic testing facility can test valves up to 56" in size from -196┬░C to ambient, under pressures up to 200 bar, using test standards to verify performance, leakage, and cycle times at cryogenic conditions. This helps assure safety and minimize issues during plant start-up.Sodium Analyzer for Industrial Applications

Sodium Analyzer for Industrial ApplicationsClassic Controls, Inc.

╠²

Meet the demanding needs of high-purity water measurements and high-acid cation exchange applications with the Thermo ScientificŌäó OrionŌäó 2111XP Sodium Analyzer. This system offers unmatched reliability in analyzing critical sample streams throughout the power/steam generation and industrial water industry. It is an all-in-one system from one of the most trusted names in sodium monitoring.Reformer Tube Inspection & Issues Affecting Tube Life

Reformer Tube Inspection & Issues Affecting Tube LifeThomas Fortinberry

╠²

This document discusses reformer tube inspection tools and issues affecting tube life. It describes an internal and external inspection system that uses laser scanning and eddy current testing to detect cracks, measure diameter expansion, and monitor creep damage in reformer tubes. Local issues like overheating, thermal shocks, and catalyst fouling can be identified. Comprehensive inspection reports are generated with results for each tube. The non-destructive testing helps assess tube condition and remaining life.Similar to Thermal Validation Equipment Rental (20)

Calibration

Calibrationsgmlab360

╠²

SGM calibration laboratory provides calibration services for a wide range of thermal, mechanical, and electrical instruments to ensure high accuracy and low measurement uncertainty. They maintain strict environmental conditions and use experienced engineers to calibrate instruments at their state-of-the-art facility or at customer sites. The calibration services include recalibration of temperature, pressure, and electrical signals in instruments such as ovens, humidity chambers, balances, meters, and sensors.Calibration introduction

Calibration introductionsigmatest21

╠²

MECHANICAL -Pressure, Mass, Volume, Torque, Sound, Force, Hardness

ELECTRO-TECHNICAL -AC/DC Voltage, AC/DC Current, Resistance, LCR, Frequency, Power Factor, Temperature Simulation

THERMAL -Temperature (-80 C to 1200 C), Humidity

These all are our specialties in Sigma Test & Research Centre Calibration's lab(link this word to http://www.sigmatest.org/calibration.html). Kindly visit our web page also for more clarity on the calibration topic.

Datasheet Fluke 9190A. Hubungi PT. Siwali Swantika 021-45850618

Datasheet Fluke 9190A. Hubungi PT. Siwali Swantika 021-45850618PT. Siwali Swantika

╠²

Datasheet Fluke Ultra-Cool Field Metrology Well. Informasi lebih detail hubungi PT. Siwali Swantika, Jakarta Office : 021-45850618 atau Surabaya Office : 031-8421264CALTECH Brochure

CALTECH BrochureDipesh Shrestha

╠²

This document provides information about calibration services offered by CALTECH PRIVATE LIMITED. It defines calibration as operations required to ensure measuring equipment is in compliance for intended use. Calibration ensures accuracy, minimizes breakdowns, meets certification requirements, and improves quality. CALTECH offers pressure, temperature, humidity, and other calibration services, using calibrated quality instruments. Their lab follows ISO/IEC 17025 guidelines and technical team consists of experienced professionals committed to quality calibration.Temperature Calibration equipment for Thermcouple, RTDs, and Pyrometers

Temperature Calibration equipment for Thermcouple, RTDs, and PyrometersTempsens Instruments

╠²

Various types of Tempsens make temperature Calibration Equipment for calibration of temperature sensors accurately. Temperature sources and master sensors

Black body sources, Reference junction units, Dry block Calibrators, Stirred Liquid Baths, Cold Junction Compensation, AUTOCAL,Industrial Temperature Calibration Selection Guide by Fluke Calibration

Industrial Temperature Calibration Selection Guide by Fluke CalibrationFluke Calibration

╠²

The Industrial Temperature Calibration Selection Guide includes information on:

Field metrology wells

Infrared calibrators

Handheld and field dry-wells

Micro-baths

Environmental monitoring

Thermometer readouts

Reference sensors Industrial temperature calibration selection guide Tools

Introduction to Temperature Measurement and Calibration Presented by Fluke Ca...

Introduction to Temperature Measurement and Calibration Presented by Fluke Ca...Transcat

╠²

This document provides an overview of temperature measurement and calibration. It discusses calibration methods like comparison calibration and fixed point calibration. Key factors for choosing temperature measurement equipment are discussed, such as sensor type, temperature range, and required accuracy. Proper placement of sensors in baths and dry wells is also covered. The importance of maintaining calibration standards and training users is emphasized.Contact temperature sensor calibration

Contact temperature sensor calibrationTempsens Instruments

╠²

Calibration of contact temperature sensors like thermocouples and RTDs. Primary and Secondary Calibration.

Fixed point method in primary calibration.

Stable temperature sources, master sensors and calibrated meter in secondary calibration.Validation Dataloggers - Jason Daoust

Validation Dataloggers - Jason Daoust ISPE_LA

╠²

Jason Daoust ŌĆō Masy Systems

Validation Dataloggers: Trends, considerations, and options in use todayBR-High-Power-Test-Lab-Brochure

BR-High-Power-Test-Lab-BrochureJohn Rodrigues (Work)

╠²

The document summarizes the testing services and capabilities of the Mersen Test Lab. The lab offers accurate testing services to improve product safety and reliability. It maintains accreditation and compliance with standards. Tests include high power testing up to 100,000 amps and 1,250 VDC, as well as high voltage, low power, and surge testing. The lab has facilities in Newburyport, MA and Saint-Bonnet-de-Mure, France to provide global testing capabilities.Fluke Process Calibration Tools Catalog

Fluke Process Calibration Tools CatalogPT. Siwali Swantika

╠²

Diskusi teknis dan info lebih lanjut, hubungi PT Siwali Swantika

ŌśÄ’ĖÅ JKT 021-45850618

ŌśÄ’ĖÅ SBY 031-8421264

Kunjungi website kami di https://siwali.com/Greystone product

Greystone productAlejandro Valencia

╠²

Greystone's vision is to design and manufacture high quality sensors for measuring temperature, humidity, pressure, and other data. They realize this vision through strict adherence to quality standards, exemplary customer service, pride in work, and research/development. Greystone produces sensors and transmitters in their 2600m2 facility in Canada and has over 100 employees in 8 locations worldwide.Industrial temperature calibrators workload matrix

Industrial temperature calibrators workload matrixFluke Calibration

╠²

Industrial temperature calibrators workload matrix. See which industrial temperature calibrator matches your workload requirements. Brought to you by Fluke Calibration.How to Use a Portable Bath to Improve Calibration of Sanitary RTD's and Trans...

How to Use a Portable Bath to Improve Calibration of Sanitary RTD's and Trans...Transcat

╠²

Learn how the Fluke Calibration 6019A and 7109A Portable Calibration Baths can improve the calibration throughput and accuracy of sanitary temperature sensors and transmitters. Since production downtime can be costly, increasing sensor calibration throughput is critical.EBSO: CATALOGO CONTROL COMPANY - TERMOMETROS-HIGROMETROS

EBSO: CATALOGO CONTROL COMPANY - TERMOMETROS-HIGROMETROSEBSO

╠²

EBSO pone a su disposici├│n el CATALOGO DE TERMOMETROS/HIGROMETROS - MARCA CONTROL COMPANY (USA)

Para adquirir el producto comun├Łquese con nosotros a los correos ventas_ebso@hotmail.com, joffreugaz@hotmail.com MadgeTech Wireless Data Loggers

MadgeTech Wireless Data LoggersMadgeTech Inc

╠²

MadgeTech offers Wireless (RF) data loggers for use in a wide variety of applications and studies. They are perfect for real-time monitoring and alarm applications.Fluke Temperature Calibration Catalog

Fluke Temperature Calibration CatalogPT. Siwali Swantika

╠²

Diskusi teknis dan info lebih lanjut, hubungi PT Siwali Swantika

ŌśÄ’ĖÅ JKT 021-45850618

ŌśÄ’ĖÅ SBY 031-8421264

Kunjungi website kami di https://siwali.com/Using a Portable Bath to Improve Calibration of Sanitary RTD's and Transmitte...

Using a Portable Bath to Improve Calibration of Sanitary RTD's and Transmitte...Transcat

╠²

Travis Porter from Fluke Calibration will describe how Portable Calibration Baths can improve the calibration throughput and accuracy of sanitary temperature sensors and transmitters.Qal 181 particulate monitor datasheet

Qal 181 particulate monitor datasheeta1-cbiss

╠²

The PCME QAL 181 is a particulate continuous emissions monitor that provides accurate measurement of low dust concentrations. It is suitable for measuring emissions from bag filters and electrostatic precipitators. The monitor has high accuracy, operates reliably at elevated temperatures, and has online calibration capabilities to minimize drift. It can measure particulate levels from 0-300 mg/m3 and integrate with data acquisition software for regulatory reporting.Katalog fluke-ir-and-contact-thermometers-by-tridinamika

Katalog fluke-ir-and-contact-thermometers-by-tridinamikaPT. Tridinamika Jaya Instrument

╠²

katalog fluke ir and contact thermometer, jual fluke ir thermometer, beli, info, harga, spesifikasi dan review

untuk informasi lebih lanjut kunjungi

www.tridinamika.com

untuk pemesanan dan pertanyaan hubungi via email

sales@tridinamika.comRecently uploaded (20)

Lessons learned when managing MySQL in the Cloud

Lessons learned when managing MySQL in the CloudIgor Donchovski

╠²

Managing MySQL in the cloud introduces a new set of challenges compared to traditional on-premises setups, from ensuring optimal performance to handling unexpected outages. In this article, we delve into covering topics such as performance tuning, cost-effective scalability, and maintaining high availability. We also explore the importance of monitoring, automation, and best practices for disaster recovery to minimize downtime.AI, Tariffs and Supply Chains in Knowledge Graphs

AI, Tariffs and Supply Chains in Knowledge GraphsMax De Marzi

╠²

How tarrifs, supply chains and knowledge graphs combine.Frankfurt University of Applied Science urkunde

Frankfurt University of Applied Science urkundeLisa Emerson

╠²

Duplicate Frankfurt University of Applied Science urkunde, make a Frankfurt UAS degree.Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

╠²

Optimal use of resources, including energy, is one of the most important principles in modern and sustainable agricultural systems. Exergy analysis and life cycle assessment were used to study the efficient use of inputs, energy consumption reduction, and various environmental effects in the corn production system in Lorestan province, Iran. The required data were collected from farmers in Lorestan province using random sampling. The Cobb-Douglas equation and data envelopment analysis were utilized for modeling and optimizing cumulative energy and exergy consumption (CEnC and CExC) and devising strategies to mitigate the environmental impacts of corn production. The Cobb-Douglas equation results revealed that electricity, diesel fuel, and N-fertilizer were the major contributors to CExC in the corn production system. According to the Data Envelopment Analysis (DEA) results, the average efficiency of all farms in terms of CExC was 94.7% in the CCR model and 97.8% in the BCC model. Furthermore, the results indicated that there was excessive consumption of inputs, particularly potassium and phosphate fertilizers. By adopting more suitable methods based on DEA of efficient farmers, it was possible to save 6.47, 10.42, 7.40, 13.32, 31.29, 3.25, and 6.78% in the exergy consumption of diesel fuel, electricity, machinery, chemical fertilizers, biocides, seeds, and irrigation, respectively. Air pollution is contamination of the indoor or outdoor environment by any ch...

Air pollution is contamination of the indoor or outdoor environment by any ch...dhanashree78

╠²

Air pollution is contamination of the indoor or outdoor environment by any chemical, physical or biological agent that modifies the natural characteristics of the atmosphere.

Household combustion devices, motor vehicles, industrial facilities and forest fires are common sources of air pollution. Pollutants of major public health concern include particulate matter, carbon monoxide, ozone, nitrogen dioxide and sulfur dioxide. Outdoor and indoor air pollution cause respiratory and other diseases and are important sources of morbidity and mortality.

WHO data show that almost all of the global population (99%) breathe air that exceeds WHO guideline limits and contains high levels of pollutants, with low- and middle-income countries suffering from the highest exposures.

Air quality is closely linked to the earthŌĆÖs climate and ecosystems globally. Many of the drivers of air pollution (i.e. combustion of fossil fuels) are also sources of greenhouse gas emissions. Policies to reduce air pollution, therefore, offer a win-win strategy for both climate and health, lowering the burden of disease attributable to air pollution, as well as contributing to the near- and long-term mitigation of climate change.

Integration of Additive Manufacturing (AM) with IoT : A Smart Manufacturing A...

Integration of Additive Manufacturing (AM) with IoT : A Smart Manufacturing A...ASHISHDESAI85

╠²

Combining 3D printing with Internet of Things (IoT) enables the creation of smart, connected, and customizable objects that can monitor, control, and optimize their performance, potentially revolutionizing various industries. oT-enabled 3D printers can use sensors to monitor the quality of prints during the printing process. If any defects or deviations from the desired specifications are detected, the printer can adjust its parameters in real time to ensure that the final product meets the required standards.Env and Water Supply Engg._Dr. Hasan.pdf

Env and Water Supply Engg._Dr. Hasan.pdfMahmudHasan747870

╠²

Core course, namely Environment and Water Supply Engineering. Full lecture notes are in book format for the BSc in Civil Engineering program. US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

╠²

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load Current Delay which delays the creation and storage of created Electromagnetic Field Energy around the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads, additional Input Power must be supplied to the Prime Mover and additional Mechanical Input Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator, an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1 MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the system.decarbonization steel industry rev1.pptx

decarbonization steel industry rev1.pptxgonzalezolabarriaped

╠²

Webinar Decarbonization steel industryTurbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

╠²

High Efficiency Chiller System in HVAC15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdf

15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdfNgocThang9

╠²

Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopiaautonomous vehicle project for engineering.pdf

autonomous vehicle project for engineering.pdfJyotiLohar6

╠²

autonomous vehicle project for engineeringIndustrial Construction shed PEB MFG.pdf

Industrial Construction shed PEB MFG.pdfPLINTH & ROOFS

╠²

"Zen and the Art of Industrial Construction"

Once upon a time in Gujarat, Plinth and Roofs was working on a massive industrial shed project. Everything was going smoothlyŌĆöblueprints were flawless, steel structures were rising, and even the cement was behaving. That is, until...

Meet Ramesh, the Stressed Engineer.

Ramesh was a perfectionist. He measured bolts with the precision of a Swiss watchmaker and treated every steel beam like his own child. But as the deadline approached, RameshŌĆÖs stress levels skyrocketed.

One day, he called Parul, the total management & marketing mastermind.

¤øæ Ramesh (panicking): "Parul maŌĆÖam! The roof isn't aligning by 0.2 degrees! This is a disaster!"

¤żö Parul (calmly): "Ramesh, have you tried... meditating?"

¤Äż Ramesh: "Meditating? MaŌĆÖam, I have 500 workers on-site, and you want me to sit cross-legged and hum ŌĆśOmŌĆÖ?"

¤ōó Parul: "Exactly. Mystic of Seven can help!"

Reluctantly, Ramesh agreed to a 5-minute guided meditation session.

¤Æ© He closed his eyes.

¤¦śŌĆŹŌÖé’ĖÅ He breathed deeply.

¤öö He chanted "Om Namah Roofaya" (his custom version of a mantra).

When he opened his eyes, a miracle happened!

¤Ä» His mind was clear.

¤ōÅ The roof magically aligned (okay, maybe the team just adjusted it while he was meditating).

¤śü And for the first time, Ramesh smiled instead of calculating load capacities in his head.

Ō£© Lesson Learned: Sometimes, even in industrial construction, a little bit of mindfulness goes a long way.

From that day on, Plinth and Roofs introduced tea breaks with meditation sessions, and productivity skyrocketed!

Moral of the story: "When in doubt, breathe it out!"

#PlinthAndRoofs #MysticOfSeven #ZenConstruction #MindfulEngineeringStructural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...

Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...slayshadow705

╠²

This presentation provides an in-depth analysis of structural quality control in the KRP 401600 section of the Copper Processing Plant-3 (MOF-3) in Uzbekistan. As a Structural QA/QC Inspector, I have identified critical welding defects, alignment issues, bolting problems, and joint fit-up concerns.

Key topics covered:

Ō£ö Common Structural Defects ŌĆō Welding porosity, misalignment, bolting errors, and more.

Ō£ö Root Cause Analysis ŌĆō Understanding why these defects occur.

Ō£ö Corrective & Preventive Actions ŌĆō Effective solutions to improve quality.

Ō£ö Team Responsibilities ŌĆō Roles of supervisors, welders, fitters, and QC inspectors.

Ō£ö Inspection & Quality Control Enhancements ŌĆō Advanced techniques for defect detection.

¤ōī Applicable Standards: GOST, KMK, SNK ŌĆō Ensuring compliance with international quality benchmarks.

¤ÜĆ This presentation is a must-watch for:

Ō£ģ QA/QC Inspectors, Structural Engineers, Welding Inspectors, and Project Managers in the construction & oil & gas industries.

Ō£ģ Professionals looking to improve quality control processes in large-scale industrial projects.

¤ōó Download & share your thoughts! Let's discuss best practices for enhancing structural integrity in industrial projects.

Categories:

Engineering

Construction

Quality Control

Welding Inspection

Project Management

Tags:

#QAQC #StructuralInspection #WeldingDefects #BoltingIssues #ConstructionQuality #Engineering #GOSTStandards #WeldingInspection #QualityControl #ProjectManagement #MOF3 #CopperProcessing #StructuralEngineering #NDT #OilAndGasOptimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

╠²

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

╠²

Thermal Validation Equipment Rental

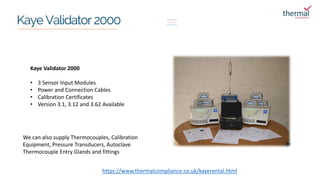

- 2. KayeValidator 2000 Kaye Validator 2000 ŌĆó 3 Sensor Input Modules ŌĆó Power and Connection Cables ŌĆó Calibration Certificates ŌĆó Version 3.1, 3.12 and 3.62 Available We can also supply Thermocouples, Calibration Equipment, Pressure Transducers, Autoclave Thermocouple Entry Glands and fittings https://www.thermalcompliance.co.uk/kayerental.html

- 3. Type T Thermocouples made to your specification Kapton Insulated Single, Three and Seven Strand. Twisted. Thermocouples LTR-140 -25 Temperature Range -25┬░C to 140┬░C Accuracy ┬▒0.1┬░C to ┬▒0.4┬░C LTR-140 -40 Temperature Range -40┬░C to 140┬░C Accuracy ┬▒0.1┬░C to ┬▒0.4┬░C HTR-400 Temperature Range 50┬░C to 400┬░C Accuracy ┬▒0.2┬░C to ┬▒0.4┬░C Calibration Baths UKAS Calibrated (ISO 17025) Temperature Range -196┬░C to 400┬░C Accuracy ┬▒0.025┬░C Calibration Certificates IRTD-400 UKAS Calibrated (ISO 17025) Tri Clamp Pressure Sensors Thermocouple Entry Glands Smart Clamps and Gaskets Entry Gland Gaskets Acessories KayeAccessories https://www.thermalcompliance.co.uk/kayerental.html

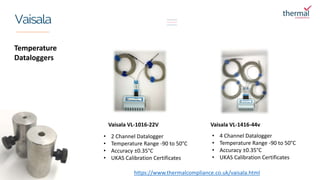

- 4. Vaisala Temperature Dataloggers Vaisala VL-1416-44v ŌĆó 4 Channel Datalogger ŌĆó Temperature Range -90 to 50┬░C ŌĆó ŌĆŗAccuracy ┬▒0.35┬░C ŌĆó UKAS Calibration Certificates Vaisala VL-1016-22V ŌĆó 2 Channel Datalogger ŌĆó Temperature Range -90 to 50┬░C ŌĆó ŌĆŗAccuracy ┬▒0.35┬░C ŌĆó UKAS Calibration Certificates https://www.thermalcompliance.co.uk/vaisala.html

- 5. Vaisala Vaisala VL-2000-20R Temperature and Humidity Loggers ŌĆó Temperature / Humidity Datalogger ŌĆó Temperature Range -20 to 50┬░C, ┬▒0.35┬░C ŌĆó Humidity Range 10-80% RH, ┬▒ 2 %RH ŌĆó Hire Includes Calibration Certificates https://www.thermalcompliance.co.uk/vaisala.html

- 6. Ellab Tracksense Pro Dataloggers Wide selection of sensors Including ŌĆó Temperature and Humidity ŌĆó Semi Flex Single and Dual Temperature ŌĆó Smart Flex Single and Dual Temperature ŌĆó Mini and Micro Loggers ŌĆó Rigid Sensors ŌĆó Pressure Sensors ŌĆó CO2 Loggers https://www.thermalcompliance.co.uk/ellab.html

- 7. Ellab Tracksense Pro Dataloggers We have sensors available for: ŌĆó Autoclave Validation ŌĆó Freeze Drier Validation ŌĆó Stability and Humidity Mapping ŌĆó CO2 Incubator Mapping ŌĆó Temperature Mapping -80 to 150┬░C ŌĆó Freezers ŌĆó Refrigerators ŌĆó Incubators ŌĆó ATEX Environments https://www.thermalcompliance.co.uk/ellab.html

- 8. 0201 ABOUT US We deliver practical and online validation training courses in: ŌĆó Autoclave Validation ŌĆó Temperature Mapping ŌĆó Steam Quality Testing ŌĆó Kaye Validator 2000 Training We can help with: ŌĆó Wet Loads ŌĆó Superheat Investigations ŌĆó Equilibration Failures ŌĆó Steam Quality Failures ŌĆó Biological Indicator Failures Consultancy 03We perform Validation on a wide range of equipment: ŌĆó LN2 Freezers ŌĆō Ovens ŌĆó Autoclaves and SIP ŌĆó Freeze Driers ŌĆó Dry Heat Processes Validation

- 9. CONTACT US www.thermalcompliance.co.uk 18 Harelands Courtyard Offices Moor Road Melsonby Richmond DL10 5NY UK Tel +44 (0)1748 327 247 www.thermalcompliance.com (Training Website) Chris Maughan Managing Director Thermal Compliance chrism@thermalcompliance.co.uk