Thermovision Test.ppt

- 1. INFRARED THERMOGRAPHY ELECTRICAL INSPECTIONS . Thermographer Level II Recent technical manuals published by National Fire Protection Association (NFPA) and the Inter-National Electrical Testing Association (NETA) prominently recommend the use of infrared inspection in the testing and maintenance of electrical systems

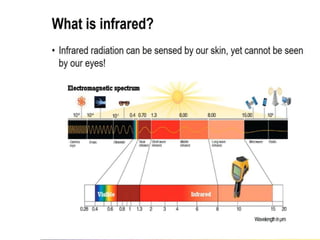

- 4. Infrared Radiation . Wavelength is longer than visible light. Infrared waves are not visible by the eye

- 5. Infrared Thermography âĒ An Infrared Camera Senses Infrared Radiation âĒ A Processor In The Camera Assigns Color To The Infrared Radiation-Different Color Equals Different Temperature âĒ Enabling Us To Visualize The Thermal World

- 8. Infrared Image Color Palette Range Is Chosen For Clarity Color Palette 2 White = T>95F Black = T<72F Color Palette 1 White = T>85F Black = T<72F 1 2 Palette 2 Is Better Suited For This Image

- 9. Some Uses Of Infrared Thermography âĒ Electrical Inspections Hot Connections Failing Components Overloaded Circuits âĒ Mechanical Inspections Motors, Bearings, Drives, Steam Systems, Boilers âĒ Fire Hot Spots People Rescue âĒ Building Thermal Envelope Roof Leaks âĒ Military âĒ Medical Severe Acute Respiratory Syndrome (SARS) âĒ Manufacturing Processes Plastics Carpet Heat/Chilling Processes âĒ Mill Operations Slag Detection âĒ Police Work Fugitive Search Drug Enforcement Missing Persons Search âĒ Animal Equine Hot Joints Ligaments

- 10. Benefits of Periodic Electrical Infrared Inspections âĒ Predictive Maintenance...Allows Scheduling Of Repairs, Forward Buying âĒ Reduces DowntimeâĶ Find It, Repair It, Before It Blows Up and Stops Production

- 12. Qualitative Infrared Electrical Inspection Exceptions: are abnormally warm components that may be a potential problem. Exceptions are usually identified by comparing the thermal patterns of like components. Qualitative Inspection: The practice of gathering information about an electrical system by observing infrared radiation, recording findings, analyzing findings, and presenting that information.

- 13. Electrical Inspection Items âĒ Transformer â Pad Mount â Dry â Overhead âĒ Service Entrance âĒ Main Switchgear âĒ Motor Control Centers âĒ Disconnects âĒ Bus Duct âĒ Distribution Panels âĒ Control Panels âĒ Rectifiers âĒ Drives âĒ Capacitor Banks âĒ Any Electrical Connection

- 14. Exception Analysis Below is an exception. One of the conductor terminals is hot. Hot Terminal TemperatureâĶ..203F Left Terminal TemperatureâĶ.156F Temperature difference is âĶâĶ 47F 119.7°F 179.5°F 120 140 160 AR01 SP01 When should you repair this exception?

- 15. Exception Repair Priority Criteria Priority 0 Temperature Difference 10F or Less No Corrective Measures Required At This Time. Priority 4 Temperature Difference Over 100F Corrective Measures Required Immediately Priority 3 Temperature Difference 30F to 100F Corrective Measures Required As Soon As Possible Priority 2 Temperature Difference 20F to 30F Corrective Measures Required As Scheduling Permits Priority 1 Temperature Difference 10F to 20F Corrective Measures Required At Next Maintenance Period

- 21. Exception Example #1 Breaker Connections Hot Spot TemperatureâĶ...203F Reference TemperatureâĶ.156F Temperature DifferenceâĶ.47F Repair Priority 3 Corrective Measures Required As Soon As Possible 119.7°F 179.5°F 120 140 160 AR01 SP01

- 22. Exception Example #2 Fuse Block 87.8°F 232.4°F 100 150 200 AR01 SP01 Hot Spot TemperatureâĶ...303F Reference TemperatureâĶ.170F Temperature DifferenceâĶ.133F Repair Priority 4 Corrective Measures Required Immediately

- 23. Exception Example #3 Breaker Connections Hot Spot TemperatureâĶ...459F Reference TemperatureâĶ..101F Temperature DifferenceâĶ.358F Repair Priority 4 Corrective Measures Required Immediately 93.0°F 144.6°F 100 110 120 130 140 AR01 SP01

- 24. Exception Example #4 Main Switchboard Fused Switch Hot Spot Temperature...311F Reference Temperature..151F Temperature Difference...160F Repair Priority 4 Corrective Measures Required Immediately 118.9°F 245.4°F 120 140 160 180 200 220 240 AR01 SP01

- 25. Exception Example #5 Breaker Load Hot Spot TemperatureâĶ.71F Reference TemperatureâĶ55F Temperature Difference..16F Repair Priority 0 No Corrective Measures Required At This Time 92.6°F 119.1°F 95 100 105 110 115 Breaker Load A-105 amps B-150 amps C-167 amps

- 26. Exception Example #6 Building Service Drop Hot Spot Temperature...301F Reference TemperatureâĶ77F Temperature Difference..224F Ambient TempâĶâĶâĶâĶ.45 F Repair Priority 4 Corrective Measures Required Immediately

- 27. Exception Example #7 Arrestor Pad Mount Transformer Hot Spot TemperatureâĶ.92F Reference Temperature...58F Temperature Difference..32F Ambient TemperatureâĶ.45F Repair Priority 3 Corrective Measures Required As Soon As Possible

- 28. Exception Example #9 Pad Mount Transformer High Side Hot Spot TemperatureâĶ.159F Reference TemperatureâĶ98F Temperature Difference..61F Ambient TemperatureâĶ.71F Repair Priority 3 Corrective Measures Required As Soon As Possible 71.9°F 124.2°F 80 90 100 110 120

- 29. Exception Example #10 Motor Drive End Bearing Hot Hot Spot TemperatureâĶ.127F Reference TemperatureâĶ99F Temperature Difference..28F Ambient TemperatureâĶ.74F Repair Priority ? Mechanical System

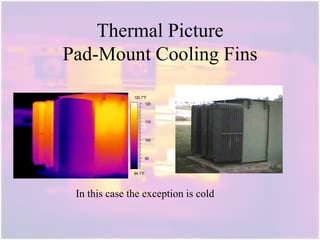

- 30. Thermal Picture Pad-Mount Cooling Fins In this case the exception is cold 84.1°F 120.7°F 90 100 110 120

- 31. Thermal Picture 480 Volt Capacitor Bank 6 1 8 1 1 1 Again the exception is cool

- 32. Infrared Tips Use a Certified Thermographer âProper Training is vital to understand thermography âCost Effective - Quality Camera is $20,000 to $50,000 Scan should cost from $800 to $1500 per day Inspect When System Load Is High âUseless To Scan Under Light or No Load âKeep in mind that an infrared electrical inspection is only a report of the electrical system at the time of the inspection. Equipment that was off or unloaded because of cycling or scheduling may have problems that were not evident at the time of the inspection. Do Inspections On A Periodic Basis --Annually Good - Semi-Annually Better (at least first couple of times) Insures that over period of time all equipment is inspected

- 33. Benefit of Electrical Infrared Inspections âĒ "...From a return on investment perspective, infrared inspection programs have proven that on average for every $1 spent on infrared electrical inspections, there is a $4 return on investment for materials and labor from fixing the problems before it fails..." "Cost/Benefits Analysis of Infrared Programs." Maintenance Technology Magazine June 2001 = $1.00 $4.00