Thesis_Jun7_2012

- 1. AXIAL COMPRESSION LOAD TRANSFER MECHANISMS OF DRILLED SHAFTS IN WEAK POROUS LIMESTONE Presentation of thesis in partial fulfill of the requirements for the degree of Master of Science in Civil Engineering JosÃĐ Roberto RamÃrez HernÃĄndez University of Puerto Rico at Mayaguez Advisor: Dr. Miguel A. Pando LÃģpez MayagÞez, Puerto Rico â Thursday June 7, 2012

- 2. IndexâĒ Goals and specific aims âĒ Introduction âĒ Site Characterization âĒ Field test program âĒ Load test results âĒ Conclusions âĒ Acknowledgments MayagÞez, Puerto Rico â Thursday June 7, 2012 2

- 3. Goals and specific aims Provide a basis for a load transfer criterion and evaluate experimentally the characteristics of the ultimate unit side resistance of drilled shafts in weak porous rock of Puerto Rico âĒ Design an experimental study of load test of drilled shafts based on high precision instrumentation âĒ Analyze data from the field tests and compare the prediction based on empirical relationships âĒ Classify and establish a geotechnical and geological characterization of the limestone rock from La MontaÃąa farm in Aguadilla, PR MayagÞez, Puerto Rico â Thursday June 7, 2012 3

- 4. Compressive axial bearing capacity MayagÞez, Puerto Rico â Thursday June 7, 2012 4

- 5. Compressive axial bearing capacity MayagÞez, Puerto Rico â Thursday June 7, 2012 5 Idealized load-displacement behavior (after Carter & Kulhawy, 1988)

- 6. Drilled shaft axial capacity MayagÞez, Puerto Rico â Thursday June 7, 2012 6 Load transfer mechanism for socketed shaft (adapted from Zhang, 1998)

- 7. Unit side shear resistance MayagÞez, Puerto Rico â Thursday June 7, 2012 7 Factors affecting the Ïmax for drilled shafts in rock Factors related to the construction Technique âĒ Interface roughness âĒ Length of time borehole remains open prior to concreting âĒ Destroyed or intact base resistance Factors related to drilled shaft geometry âĒ Length âĒ Diameter Factors related to the load test method âĒ Rate of load applied

- 8. Unit side shear resistance MayagÞez, Puerto Rico â Thursday June 7, 2012 8 Interface roughness Wall roughness classification from Pells et al. (1980) Roughness Classification Description R1 Straight, smooth-side shaft, grooves or indentation less than 1.00 mm deep R2 Grooves of depth 1-4 mm, width greater than 2 mm, at spacing 50 to 200 mm. R3 Grooves of depth 4-10 mm, width > 5 mm, at spacing 50 to 200 mm. R4 Grooves or undulations of depth greater than 10, width > 10mm, at spacing 50 to 200 mm. Parameters for defining shaft wall roughness (after Horvath et al., 1980 and Kodikara et al., 1992) Upper and lower bound guidelines for effective roughness adapted from (Seidel and Collingwood, 2001)

- 9. Unit side shear resistance MayagÞez, Puerto Rico â Thursday June 7, 2012 9 Factors related to drilled shaft geometry Unit side shear versus displacement for drilled shafts socket in rock with qu = 3 MPa (after Baycan, 1996)

- 10. Unit side shear resistance MayagÞez, Puerto Rico â Thursday June 7, 2012 10 Factors related to the load test method Comparison of typical Load-Displacement behavior four test procedures (adapted from Fellenius, 1975) 0 20 40 60 80 100 120 140 160 180 0 1 2 3 4 5 6 7 8 Load Displacement CRP Quick ML Cyclic

- 11. Unit side shear resistance MayagÞez, Puerto Rico â Thursday June 7, 2012 11 Reference Îą Îē C 1 Rosenberg and Jouneaux (1976) 0.34 0.51 1.05 2 Horvath (1978) 0.33 0.50 1.04 3 Horvath and Kenney (1979) lower bound 0.21 0.50 0.65 Horvath and Kenney (1979) upper bound 0.25 0.50 0.78 4 Meigh and Wolski (1979) 0.22 0.60 0.55 5 Reynolds and Kaderabek (1980) 0.30 1.00 0.30 6 Pells et al. (1980) R1, R2 & R3 0.40 0.50 1.26 Pells et al. (1980) R4 0.80 0.50 2.52 7 Williams et al. (1980) 0.44 0.37 1.85 8 Horvath (1982) smooth 0.20 0.50 0.63 9 Horvath (1982) roughness 0.30 0.50 0.95 10 Gupton and Logan (1984) 0.20 1.00 0.20 Reference Îą Îē C 11 Rowe and Armitage (1984) smooth 0.45 0.50 1.42 Rowe and Armitage (1984) roughness 0.60 0.50 1.89 12 Reese and O'Neill (1987) 0.15 1.00 0.15 13 Carter and Kulhawy (1988) 0.2 0.50 0.63 14 Toh et al. (1989) 0.25 1.00 0.25 15 Kulhawy and Phoon (1993) 0.35 0.50 1.10 16 O'Neill and Reese (1999) 0.21 0.50 0.66 17 Zhang and Einstein (1998) lower bound 0.20 0.50 0.63 Zhang and Einstein (1999) upper bound 0.40 0.50 1.26 18 Prakoso (2002) lower bound 0.20 0.50 0.63 Prakoso (2002) upper bound 0.32 0.50 1.00 19 Kulhawy et al. (2005) 0.32 0.50 1.00 20 Turner (2006) 0.32 0.50 1.00 Summary of relations between t and qu (expanded version from OâNeill et al., 1996)

- 12. Unit end bearing resistance MayagÞez, Puerto Rico â Thursday June 7, 2012 12 Design Method ðķ ð ð· ð Teng (1962) [5-8] 1 Coates (1967) 3 1 Rowe and Armitage (1987) 2.7 1 Zhang and Einstein (1998) 4.5 1 ARGEMA (1992) [3-6.6] 0.5 Empirical relationships between ð ðĒ and ð ðððĨ(expanded version from Zhang & Einstein, 1998) âĒ Between 10% - 20% (Williams et al., 1980; Carter & Kulhawy, 1988) âĒ A significant relative movement between concrete and rock is necessary to achieve the total end bearing resistance (Qb) âĒ Some methods proposed for predict (Qb) are based on elastic solutions and depend on the embedment ratio (L/B) and the rate of stiffness (Ec/Er) Theoretical base load transfer (adapted from Rowe and Armitage, 1987b) ð ðððĨ = ðž ð ð ðĒ ð― ð

- 13. Weak rock / IGMâs definition MayagÞez, Puerto Rico â Thursday June 7, 2012 13 Weak rock Weathered and broken rock (BS, 8004) Indurated soil (Oliveira, 1993) Soft rock (Johnston, 1989) Intermediate geo-material IGM (FHWA, 1995) IGM strength classification based on qu versus ð ððð (adapted from Kulhawy and Phoon, 1993)

- 14. Summary MayagÞez, Puerto Rico â Thursday June 7, 2012 14 âĒ Demand of loads of great magnitude âĒ 1976 â 2006 âĒ Range of estimation to predict Qs 86% â 93% âĒ The 27.5% geomorphology area of Puerto Rico is conformed fro three karst zones (North, South and disperse) âĒ $ versus capacity 0 5 10 15 20 25 30 10 30 50 70 90 110 130 150 Ïmax/Pa qu/Pa Rosenberg and Jouneaux (1976) Horvath (1978) Horvath and Kenney (1979) lower bound Horvath and Kenney (1979) upper bound Meigh and Wolski (1979) Reynolds and Kaderabek (1980) Pells et al. (1980) R1, R2 & R3 Pells et al. (1980) R4 Williams et al. (1980) Horvath (1982) smooth Horvath (1982) roughness Gupton and Logan (1984) Rowe and Armitage (1984) smooth Rowe and Armitage (1984) roughness Reese and O'Neill (1987) Carter and Kulhawy (1988) Toh et al. (1989) Kulhawy and Phoon (1993) O'Neill and Reese (1999) Zhang and Einstein (1998) lower bound Zhang and Einstein (1999) upper bound Prakoso (2002) lower bound Kulhawy et al. (2005) Turner (2006)

- 15. Site Characterization MayagÞez, Puerto Rico â Thursday June 7, 2012 15 âĒ Location General location map of test site not to scale (adapted from www.mapsof.net ÂĐ 2012) Aerial image showing location of experimental farm La MontaÃąa (from Google Earth ÂĐ2012) Aerial images showing general location of test site (from Google Earth ÂĐ 2012)

- 16. Site Characterization MayagÞez, Puerto Rico â Thursday June 7, 2012 16 Geology Geological map of Puerto Rico (adapted from Renken et al., 2002) Elevation view of the North Coast Belt of Puerto Rico (adapted from Renken et al., 2002) Ta

- 17. Site Characterization MayagÞez, Puerto Rico â Thursday June 7, 2012 17 Engineering properties Drilled shafts load test and site investigation layout (not to scale) Thermo-gravimetric analyses (TGA) of AymamÃģn limestone

- 18. Site Characterization MayagÞez, Puerto Rico â Thursday June 7, 2012 18 Boring log DS_A2 Drilled shafts load test and site investigation layout (not to scale) Stress-Strain diagram for AymamÃģn limestone (UCS) test

- 19. Field test program MayagÞez, Puerto Rico â Thursday June 7, 2012 19 General test layout Layout of load test arrangement Setup and arrangement of axial compressive load test

- 20. Field test program MayagÞez, Puerto Rico â Thursday June 7, 2012 20 Field test program Layout of load test arrangement 1 2 0 10 20 30 40 50 60 70 0 50 100 150 200 250 300 time(min) Load (kips) Duration of Load Test 0 5 10 15 20 25 30 0 50 100 150 200 250 300 time(sec) Load (kips) Duration of Load Test

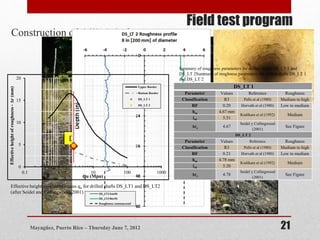

- 21. Field test program MayagÞez, Puerto Rico â Thursday June 7, 2012 21 Construction of drilled shafts Layout of load test arrangement 1 2 DS_LT 1 DS_LT 2 0 5 10 15 20 0.1 1 10 100 1000 Effectiveheightofroughness-Îr(mm) qu (Mpa) Upper Border Bottom Border DS_LT 1 DS_LT 2 DS_LT 1 Parameter Values Reference Roughness Classification R3 Pells et al (1980) Medium to high RF 0.20 Horvath et al (1980) Low to medium hm 4.67 mm Kodikara et al (1992) Medium isd 5.51 Îre 4.67 Seidel y Collingwood (2001) See Figure DS_LT 2 Parameter Values Reference Roughness Classification R3 Pells et al (1980) Medium to high RF 0.21 Horvath et al (1980) Low to medium hm 4.78 mm Kodikara et al (1992) Medium isd 5.20 Îre 4.78 Seidel y Collingwood (2001) See Figure Effective height roughness versus qu for drilled shafts DS_LT1 and DS_LT2 (after Seidel and Collingwood, 2001) Summary of roughness parameters for drilled shafts DS_LT 1 and DS_LT 2Summary of roughness parameters for drilled shafts DS_LT 1 and DS_LT 2

- 22. Field test program MayagÞez, Puerto Rico â Thursday June 7, 2012 22 Construction of drilled shafts

- 23. Results MayagÞez, Puerto Rico â Thursday June 7, 2012 23 DS_LT1 0.974 0.0 0.2 0.4 0.6 0.8 1.0 1.2 0 50 100 150 200 250 300 Displacementoftoppile(in) Load (kips) 1 sequence 2 sequence 3 sequence Load versus displacement for the drilled shaft DS_LT 1 0 200 400 600 800 1,000 1,200 0 50 100 150 200 250 300 Âĩstrain Load (kips) EGP1 (ÂĩÉ) level 46.25 in EGP2 (ÂĩÉ) level 34.35 in EGP3 (ÂĩÉ) level 21.75 in EGP4 (ÂĩÉ) level 9.75 in EGP5 (ÂĩÉ) level - 4.25 in Load applied versus strains for drilled shaft DS_LT 1

- 24. Results MayagÞez, Puerto Rico â Thursday June 7, 2012 24 DS_LT2 Load versus displacement for the drilled shaft DS_LT 2 0.773 0.0 0.2 0.4 0.6 0.8 1.0 1.2 0 50 100 150 200 250 300 Displacementoftoppile(in) Load (kips) 0 200 400 600 800 1,000 1,200 0 50 100 150 200 250 300 Âĩstrain Load (kips) EGP1 (ÂĩÉ) level 49.5 in EGP2 (ÂĩÉ) level 36.5 in EGP3 (ÂĩÉ) level 23.25 in EGP4 (ÂĩÉ) level 9.5 in EGP5 (ÂĩÉ) level -4.5 in Load applied versus strain for drilled shaft DS_LT 2

- 25. Results MayagÞez, Puerto Rico â Thursday June 7, 2012 25 250.56 12.85 -12 0 12 24 36 48 60 0 100 200 300 Depth(in) Load (kips) Q= 15 kips Q= 25 kips Q= 40 kips Q= 45 kips Q= 65 kips Q= 100 kips Q= 165 kips Q= 215 kips Q= 250 kips Qs max Qs min Load distributions for drilled shaft DS_LT 1 272.20 5.46 -12 0 12 24 36 48 60 0 100 200 300 Depth(in) Load (kips) Q= 10 kips Q= 25 kips Q= 35 kips Q= 45 kips Q= 65 kips Q= 100 kips Q= 150 kips Q= 200 kips Q= 230 kips Q= 250 kips Q= 270 kips Q max Q min Load distributions for drilled shaft DS_LT 2

- 26. Results MayagÞez, Puerto Rico â Thursday June 7, 2012 26 Maximum skin friction mobilized for drilled shaft DS_LT 1 Maximum skin friction mobilized for drilled shaft DS_LT 2 0 10 20 30 40 50 0 200 400 600 Depth(in) Unit side shear resistance mobilized (psi) Q=20 kips Q=25 kips Q=45 kips Q= 67 kips Q= 100 kips Q= 165 kips Q= 215 kips Q= 250 kips 0 10 20 30 40 50 0 200 400 600 Depth(in) Unit side shear resistance mobilized (psi) Q= 272 kips Q= 200 kips Q= 150 kips Q= 100 kips Q= 75 kips Q= 50 kips Q= 25 kips Q= 10 kips

- 27. Comparative prediction - measured MayagÞez, Puerto Rico â Thursday June 7, 2012 27 275 250 333.21 49.01 0 100 200 300 400 500 600 700 800 150 350 550 750 950 1150 1350 Drilledshaftloadcapacity-Qu(psi) Unconfined compressive strength - qu (psi) Carter and Kulhawy (1988) Pells et al. (1980) R4 Limestone DS_LT 2 (Q measured) DS_LT 1 (Q measured) Qu DS_LT 2 est Qu DS_LT 1 est Qtu e

- 28. Conclusions MayagÞez, Puerto Rico â Thursday June 7, 2012 28 âĒ Shafts roughness index factor âĒ Shaft geometry - diameter and length âĒ Rate of load method âĒ Classification of limestone from the AymamÃģn formation in La Montana farm âĒ Pells et al. (1980). â other correlations âĒ The behavior of the drilled shafts tested âĒ Future work â La Montana farm

- 29. Acknowledgments âĒ Family âĒ Geo-Cim Inc, Dywidag-Systems International, MS Drills, Structural Steel Manufacturing, Inc. âĒ Mr. AÃąeses and all the people which work in the La MontaÃąa farm âĒ Augusto Ortiz, Manuel Collazo âĒ Dr. Ricardo Ramos, Dr. Daniel Wendichansky, and Dr. Miguel Pando âĒ Friends âĒ PRSN â Christa and Victor âĒ Finally, thanks Ana, AndrÃĐ & Mateo Puerto Rico Seismic Network (PRSN) â January 17th, 2012 29

- 30. Puerto Rico Seismic Network (PRSN) â January 17th, 2012 30

Editor's Notes

- Mecanismos de transferencia de carga axial a compresion de fustes barrenados en roca caliza y porosa

- a) Carga total aplicada menor a la resistencia unitaria al corte, b) Carga aplicada aumenta pero aun menora a la resitencia ultima unitaria al corte, c) carga aplicada mayor, se alcanza la resistencia unitaria al corte ultima y se genera la reaccion de la punta del pilote. d) carga ultima del pilote es la suma de la resistencia ultima al corte y la resistencia ultima de la punta o base del pilote.

- En la medida en que se va aumentando la carga a compresion, la curva carga desplazamiento mostrara un comportamiento lineal al momento de alcanzar la resistencia unitaria al corte ultima, la curva ya no mostrara un comportamiento lineal y entrara en una zona de transision. Provocando un mayor desplazamiento con incrementos de carga menores hasta que ocurre un deslizamiento pleno donde la resistencia unitaria al corte ultima se ha sobre pasado.

- DS_LT1 carga mas lenta, menor carga para un desplazamiento igual que para una carga rapida DS_LT2 que requiere una carga mayor. Desplazamientos mayores para cargas mas lentas â Desplazamientos menores para cargas mas rapidas.

- BS 8004 â Roca fracturada o meteorizada Johnston 1989 â roca blanda Oliveira 1993 â suelo endurecido IGM 1995 Rango en psi [ ] Mpa [ ]

- Costo de drilled shafts por pie de profundidad vrs diametro Hormigon ($105/yrd3).

- Roca sedimentaria 23.5 millones de anos, era cenozoica terciaria (Ta), edad del mioceno temprano. 88% Ca,

- Porosidad 41.17%, relacion de vanos de .7, peso especifico seco 102 pcf,

- Carga maxima por pie de profundidad comparar con velocidad de aplicacion de carga.

![Unit end bearing resistance

MayagÞez, Puerto Rico â Thursday June 7, 2012 12

Design Method ðķ ð ð· ð

Teng (1962) [5-8] 1

Coates (1967) 3 1

Rowe and Armitage (1987) 2.7 1

Zhang and Einstein (1998) 4.5 1

ARGEMA (1992) [3-6.6] 0.5

Empirical relationships between ð ðĒ and ð ðððĨ(expanded version from Zhang & Einstein, 1998)

âĒ Between 10% - 20% (Williams et al., 1980; Carter & Kulhawy, 1988)

âĒ A significant relative movement between concrete and rock is necessary to achieve

the total end bearing resistance (Qb)

âĒ Some methods proposed for predict (Qb) are based on elastic solutions and depend

on the embedment ratio (L/B) and the rate of stiffness (Ec/Er)

Theoretical base load transfer (adapted from Rowe and Armitage, 1987b)

ð ðððĨ = ðž ð ð ðĒ

ð― ð](https://image.slidesharecdn.com/c2646c1b-2f25-428a-b1ff-3a6e2a52e43c-150210095801-conversion-gate02/85/Thesis_Jun7_2012-12-320.jpg)