Thw sepcon danube_flood

- 1. Technomar SEPCONTechnomar SEPCON Oil/Water Separation UnitsOil/Water Separation Units Employed by the THWEmployed by the THW during the 2013 Danubeduring the 2013 Danube Flood in Southern GermanyFlood in Southern Germany

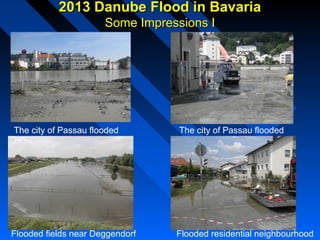

- 2. 2013 Danube Flood in Bavaria2013 Danube Flood in Bavaria Some Impressions ISome Impressions I The city of Passau flooded The city of Passau flooded Flooded fields near Deggendorf Flooded residential neighbourhood

- 3. 2013 Danube Flood in Bavaria2013 Danube Flood in Bavaria Some Impressions ISome Impressions I Flooded car dealership in Fischdorf Flood-damaged shop in Fischdorf

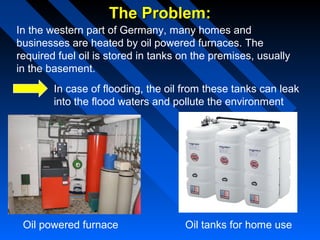

- 4. The Problem:The Problem: In the western part of Germany, many homes and businesses are heated by oil powered furnaces. The required fuel oil is stored in tanks on the premises, usually in the basement. In case of flooding, the oil from these tanks can leak into the flood waters and pollute the environment Oil powered furnace Oil tanks for home use

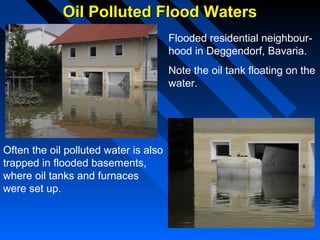

- 5. Oil Polluted Flood WatersOil Polluted Flood Waters Flooded residential neighbour- hood in Deggendorf, Bavaria. Note the oil tank floating on the water. Often the oil polluted water is also trapped in flooded basements, where oil tanks and furnaces were set up.

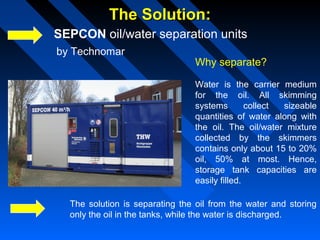

- 6. The Solution:The Solution: SEPCON oil/water separation units Why separate? Water is the carrier medium for the oil. All skimming systems collect sizeable quantities of water along with the oil. The oil/water mixture collected by the skimmers contains only about 15 to 20% oil, 50% at most. Hence, storage tank capacities are easily filled. The solution is separating the oil from the water and storing only the oil in the tanks, while the water is discharged. by Technomar

- 7. SEPCON 80SEPCON 80 SEPCON units are compact oil/water separation systems with the dimensions of a standard ISO 20â container. SEPCON units are designed for mobility and may be employed wherever needed. Every SEPCON unit is equipped with a diesel engine and therefore independent of outside power supply. Throughput: 80 mÂģ/h Length: 6.06 m = 20 ft Width: 2.44 m = 8 ft Height: 2.59 m = 8.5 ft Weight empty: 10 000 kg Weight full: 25 000 kg Max. oil content: < 50% Max. viscosity: 70 000 cSt Max. density: 0.99 g/mÂģ Flashpoint: > 60°C SEPCON units separate oil and water in a direct throughflow process, utilizing only the physical principles of gravity and coalescence. Chemical additives and long settling periods are not necessary.

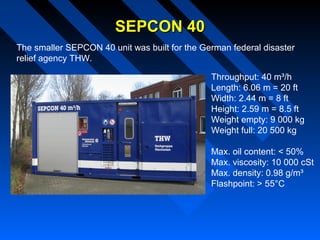

- 8. SEPCON 40SEPCON 40 The smaller SEPCON 40 unit was built for the German federal disaster relief agency THW. Throughput: 40 mÂģ/h Length: 6.06 m = 20 ft Width: 2.44 m = 8 ft Height: 2.59 m = 8.5 ft Weight empty: 9 000 kg Weight full: 20 500 kg Max. oil content: < 50% Max. viscosity: 10 000 cSt Max. density: 0.98 g/mÂģ Flashpoint: > 55°C

- 9. The German government has 10 SEPCON units stationed all over Germany, so they may be quickly deployed whenever needed. Operated by the THW: LÞbeck (SEPCON 80) Nordenham (SEPCON 80) Cloppenburg (SEPCON 40 Berlin (SEPCON 40) Essen (SEPCON 40 Borna (SEPCON 40) Frankfurt/Main (SEPCON 40) Obernburg (SEPCON 40) Kelheim (SEPCON 40) Operated by the Fire Brigade: Hamburg (SEPCON 80)

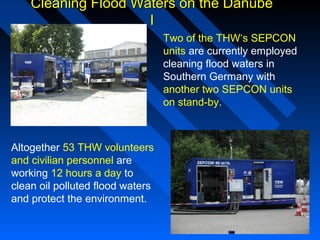

- 10. Cleaning Flood Waters on the DanubeCleaning Flood Waters on the Danube II Two of the THWâs SEPCON units are currently employed cleaning flood waters in Southern Germany with another two SEPCON units on stand-by. Altogether 53 THW volunteers and civilian personnel are working 12 hours a day to clean oil polluted flood waters and protect the environment.

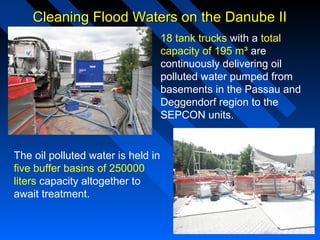

- 11. Cleaning Flood Waters on the Danube IICleaning Flood Waters on the Danube II 18 tank trucks with a total capacity of 195 mÂģ are continuously delivering oil polluted water pumped from basements in the Passau and Deggendorf region to the SEPCON units. The oil polluted water is held in five buffer basins of 250000 liters capacity altogether to await treatment.

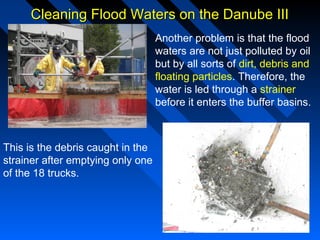

- 12. Cleaning Flood Waters on the Danube IIICleaning Flood Waters on the Danube III Another problem is that the flood waters are not just polluted by oil but by all sorts of dirt, debris and floating particles. Therefore, the water is led through a strainer before it enters the buffer basins. This is the debris caught in the strainer after emptying only one of the 18 trucks.

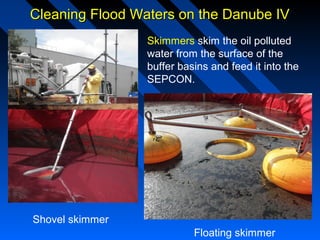

- 13. Cleaning Flood Waters on the Danube IVCleaning Flood Waters on the Danube IV Skimmers skim the oil polluted water from the surface of the buffer basins and feed it into the SEPCON. Shovel skimmer Floating skimmer

- 14. The Separation ProcessThe Separation Process Oil residual water content: less than 1% Oil/water mixture oil content: up to 50% viscosity: up to 70 000 cSt density: up to 0.99 g/cmÂģ flashpoint: > 60°C Water: residual oil content: less than 15 ppm Separation Unit Throughput: 80/40 mÂģ/h

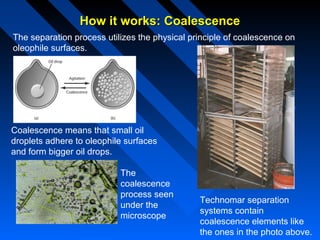

- 15. How it works: CoalescenceHow it works: Coalescence The separation process utilizes the physical principle of coalescence on oleophile surfaces. Coalescence means that small oil droplets adhere to oleophile surfaces and form bigger oil drops. The coalescence process seen under the microscope Technomar separation systems contain coalescence elements like the ones in the photo above.

- 16. After the Separation IAfter the Separation I After the separation, the separated oil is taken by tank trucks to the OMV refinery in Vohburg, Bavaria. To date, 250 mÂģ of pure oil have been separated and could be reused. Otherwise this oil would have polluted the environment.

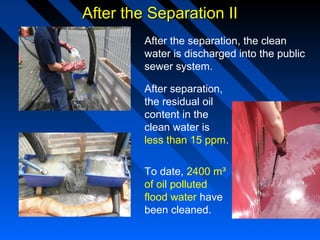

- 17. After the Separation IIAfter the Separation II After the separation, the clean water is discharged into the public sewer system. After separation, the residual oil content in the clean water is less than 15 ppm. To date, 2400 mÂģ of oil polluted flood water have been cleaned.

- 18. Technomar SEPCON 40/80Technomar SEPCON 40/80 Helping the THW with the flood clean-up work in Bavaria.

- 19. How to Contact UsHow to Contact Us TECHNOMAR GmbH & Co.KG Carl-Stockhinger-StraÃe 6 D-28197 Bremen Germany Managing Director: Mr Matthias Wichmann Tel.: +49-421-54 90 9-0 Fax: +49-421-54 90 9-50 info@technomar-bremen.de www.technomar-bremen.de Our Company Headquarters: Our representative for South Eastern Europe: Danube Rainbow SRL 27 Alexandru Cernat Str. 800087 Galati Romania Managing Director: Mr Victor Ionitza Tel/Fax:+40-236-463958 Mobile:+40-722-640797 danuberainbow@clicknet.ro

- 20. Contact at the THWContact at the THW Thomas H. Janke, Dipl.-Ing. Head of unit: Oil spill combating / CBRN protection co THW-GeschÃĪftstelle Bremen TogostraÃe 44 28239 Bremen Tel.     : +49 421 222758-1 Fax.    : +49 421 222758-9 Mobil: +49 175 2636990 mail   : thomas.janke@thw.de mail   : oel-abc.lvhbni@thw.de

- 21. CreditsCredits Photos by: THW, Technomar, Wikimedia Text by: Cora Buhlert Presentation created by: Cora Buhlert http://corabuhlert.com