Tomato products

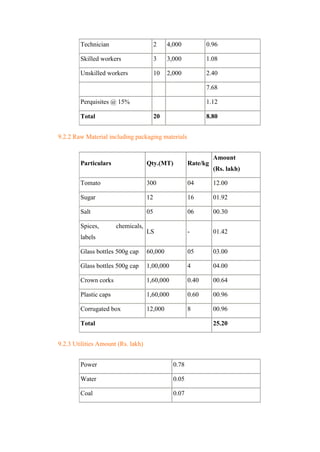

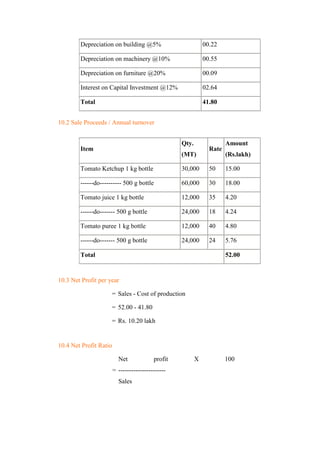

- 1. Tomato Products<br />Quality and Standards:As per FPO specificationsProduction Capacity/Annum:Tomato ketchup 60MT  Tomato juice 24 MT  Tomato puree 24 MTUploaded on:October 2007<br />1.0 Product and Its Applications<br />A number of tomato products e.g. ketchup, juice, puree, paste, sauce, pickles are available in the market. These are items of common use in households, hotels, restaurants, institutions. Tomato puree is used as a substitute to fresh tomato during cooking. Ketchup is a sweet spicy food adjunct. Tomato juice is nutritious and appealing juice in taste.<br />2.0 Market Potential<br />With the increasing living standards and rapid urbanization, the demand for tomato products is going up. Tomato puree finds a big market in households when market price of fresh tomato is high. Besides the fast food chains have boosted the consumption of tomato products.<br />3.0 Basis and Presumptions<br />a) The unit will work for 300 days per annum on single shift basis. b) The unit can achieve its full capacity utilization during the 3rd year of operation. c) The wages for skilled workers are taken as per prevailing rates in this type of industry. d) Interest rate for total capital investment is calculated @ 12% per annum. e) The entrepreneur is expected to raise 20-25% of the capital as margin money. f) The unit would construct its own building as per F.P.O. specifications. g) Costs of machinery and equipment are based on average prices of machinery manufacturers.<br />4.0 Implementation Schedule<br />Project implementation will take a period of 8 months. Break- up of the activities and relative time for each activity is shown below:<br />Scheme preparation and approval:01 monthSSI provisional registration:1-2 monthsSanction of financial supports etc.:2-5 monthsInstallation of machinery and power connection:6-8 monthsTrial run and production:01 month<br />5.0 Technical Aspects 5.1 Location<br />The unit can be set up at a suitable location where tomatoes are available in abundance. Availability of road, skilled manpower, power, water are also to be considered while selecting the location.<br />5.2 Process of Manufacture<br />Fully ripe, sound fruits having thick pulp and bright red colour are selected. These are washed, stemmed and cut into small pieces and cooked in a kettle till the skin easily separates. The heated tomatoes are passed through a pulper to remove the skin and seeds. For making juice, sugar and salt are added and product heated to 85-90 degree C. Hot juice is filled in glass bottles, crown corked and sterilized in boiling water. For making puree, the juice is concentrated to 9-12 degree brix. The product is filled hot in bottles, crown corked and sterilized in boiling water. For ketchup making, the juice obtained above is concentrated along with sugar, salt, spices, preservative to about 28 degree brix. It is filled hot in glass bottles, crown corked.<br />5.3 Quality Control and Standards: As per FPO requirements<br />6.0 Pollution Control<br />There is no major pollution problem associated with this industry except for disposal of waste which should be managed appropriately. The entrepreneurs are advised to take quot; No Objection Certificatequot; from the State Pollution Control Board.<br />7.0 Energy Conservation<br />The fuel for the steam generation in the boiler is coal or LDO depending upon the type of boiler. Proper care should be taken while utilizing the fuel for the steam production. There should be no leakage of steam in the pipe lines and adequate insulation should be provided.<br />8.0 Production Capacity<br />Quantity:Ketchup:60+Juice:24+Puree:24 tpaInstalled capacity:300 tpa tomatoOptimum capacity utilization:70%Working days:300/annumManpower:20UtilitiesMotive Power:15 kWWater:10 kL/dayCoal/LD oil:250 Kg/day<br />9.0 Financial Aspects 9.1 Fixed Capital<br />9.1.1 Land & BuildingAmount (Rs. lakh)Land 500 sq.mtr0.75Built up Area 150 sq. mtr.4.50Total cost of Land and Building5.25<br />9.1.2 Machinery and Equipment<br />DescriptionAmount (Rs. lakh)Steam boiler, washing machine, s.s. steam jacketted kettles, pulper, processing tank, bottle washing unit, vacuum filling machine, weighing balance, crown corking machine, working tables, handling equipment5.50Erection and electrification @ 10% of machinery cost0.55Office furniture & fixtures0.45Total6.50<br />9.1.3 Pre-operative Expenses<br />Consultancy fee, project report, deposits with electricity department etc.0.85<br />9.1.4 Total Fixed Capital<br />(9.1.1+9.1.2+9.1.3)12.6<br />9.2 Recurring expenses per annum9.2.1 Personnel<br />DesignationNo.Salary Per monthAmount (Rs.lakh)Factory Manager18,0000.96Supervisor25,0001.20Office Assistant24,5001.08Technician24,0000.96Skilled workers33,0001.08Unskilled workers102,0002.40   7.68Perquisites @ 15%  1.12Total20 8.80<br />9.2.2 Raw Material including packaging materials<br />ParticularsQty.(MT)Rate/kgAmount (Rs. lakh)Tomato3000412.00Sugar121601.92Salt050600.30Spices, chemicals, labelsLS-01.42Glass bottles 500g cap60,0000503.00Glass bottles 500g cap1,00,000404.00Crown corks1,60,0000.4000.64Plastic caps1,60,0000.6000.96Corrugated box12,000800.96Total25.20<br />9.2.3 Utilities Amount (Rs. lakh)<br />Power0.78Water0.05Coal0.07Total0.90<br />9.2.4 Other Contingent ExpensesAmount (Rs. lakh)Repairs and maintenance@10%1.10Consumables & spares0.40Transport & Travel0.30Publicity1.12Postage & stationery0.25Telephone0.12Insurance0.11Total3.40<br />9.2.5 Total Recurring ExpenditureAmount (Rs. lakh)(9.2.1+9.2.2+9.2.3+9.2.4)38.30<br />9.3 Working Capital<br />Recurring Expenditure for 3 months9.57<br />9.4 Total Capital InvestmentAmount (Rs. lakh)Fixed capital (Refer 9.1.4)12.60Working capital (Refer 9.3)9.57Total22.17<br />10.0 Financial Analysis<br />10.1 Cost of Production (per annum)Amount (Rs. lakh)Recurring expenses (Refer 9.2.5)38.30Depreciation on building @5%00.22Depreciation on machinery @10%00.55Depreciation on furniture @20%00.09Interest on Capital Investment @12%02.64Total41.80<br />10.2 Sale Proceeds / Annual turnover<br />ItemQty. (MT)RateAmount (Rs.lakh)Tomato Ketchup 1 kg bottle30,0005015.00------do---------- 500 g bottle60,0003018.00Tomato juice 1 kg bottle12,000354.20------do------- 500 g bottle24,000184.24Tomato puree 1 kg bottle12,000404.80------do------- 500 g bottle24,000245.76Total52.00<br />10.3 Net Profit per year=Sales - Cost of production=52.00 - 41.80=Rs. 10.20 lakh<br />10.4 Net Profit Ratio=Net profit X 100 ---------------------- Sales  =10.20X 100 ------------------- 41.80  =24.40%<br />10.5 Rate of Return on Investment<br />=Net profit X 100 ---------------------------- Capital Investment =10.20X 100 ----------------------- 22.17 == 46.01%<br />10.6 Annual Fixed CostAmount (Rs. Lakh)All depreciation0.86Interest2.6440% of salary, wages, utility, contingency5.24Insurance0.11Total8.85<br />10.7 Breakeven Point<br />=Annual Fixed Cost X 100 ----------------------------------- Annual Fixed Cost + Profit =8.85 X 100 ------------------ 8.85 + 10.20 =0.4646<br />11.0 Addresses of Machinery and Equipment Suppliers<br />Batliboi Engineers (Bangalore) Pvt. Ltd. 99/2&3, N.R.Road Bangalore – 560 002<br />B.Sen Barry & Co. 65/11, New Rohtak Road New Delhi – 110 005<br />Gardners Corporation 158 Golf Links, New Delhi – 110 003<br />Narene Tulaman Manufacturers Pvt. Ltd. Balanagar Hyderabad – 500 037<br />Raylon Metal Works Kondivitta Lane Post Box 17426 J.B.Nagar, Andheri (E) Mumbai – 400 059<br />Bajaj Maschinen Pvt. Ltd. 7/20-7/27 Jai Laxmi Industrial Estate, Site IV Sahibabad Industrial Area - 201010 Dist.Ghaziabad, UP<br />12.0 Other Special Features <br />A careful selection of product mix is necessary based on the local market demand and availability of raw materials. The facilities can also be utilised to manufacture other tomato products, bottled fruit juices, jams, jelly etc. for fuller utilisation of capacity.<br />