Tower crane

- 1. WELCOME TO OUR PRESENTATIO N FARID AFFENDY B. MOHD. FAIZAL MOHD. SHAZWAN B. SHERIDAN MUHAMMAD RUZAINI B. M. HARON YESSI FAUZIAH BT. MARWAN MDM. ROSNAH BT. ABD. RAHMAN (OSH 2213)

- 2. INTRODUCTIO N : TOWER CRANE  Tower CRANE is a jib or  Tower cranes often give the boom crane mounted on a best COMBINATION tower structure, of height and lifting demountable or permanent, capacity and are used in including both horizontal and the construction of tall luffing jib types. buildings.  Tower cranes are commonly  The construction crew employed in uses the tower crane to CONSTRUCTION LIFT INDUSTRY for the MATERIALS such movement of materials . as steel, concrete, large tools and generators. OCCUPATIONAL SAFETY (OSH

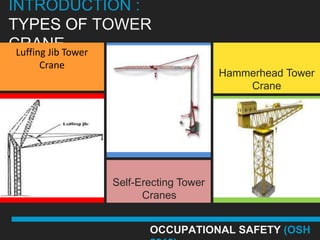

- 3. INTRODUCTION : TYPES OF TOWER CRANETower Luffing Jib Crane Hammerhead Tower Crane Self-Erecting Tower Cranes OCCUPATIONAL SAFETY (OSH

- 4. INTRODUCTION : ERECTION OF TOWER CRANE OCCUPATIONAL SAFETY (OSH

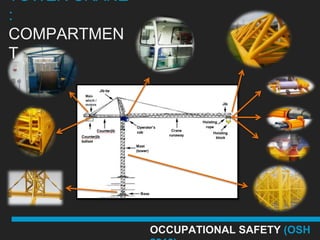

- 5. TOWER CRANE : COMPARTMEN T OCCUPATIONAL SAFETY (OSH

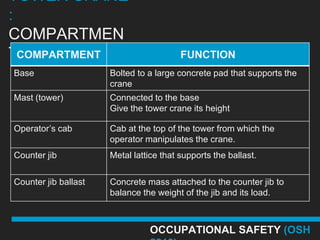

- 6. TOWER CRANE : COMPARTMEN TCOMPARTMENT FUNCTION Base Bolted to a large concrete pad that supports the crane Mast (tower) Connected to the base Give the tower crane its height Operator’s cab Cab at the top of the tower from which the operator manipulates the crane. Counter jib Metal lattice that supports the ballast. Counter jib ballast Concrete mass attached to the counter jib to balance the weight of the jib and its load. OCCUPATIONAL SAFETY (OSH

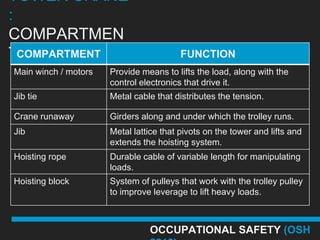

- 7. TOWER CRANE : COMPARTMEN TCOMPARTMENT FUNCTION Main winch / motors Provide means to lifts the load, along with the control electronics that drive it. Jib tie Metal cable that distributes the tension. Crane runaway Girders along and under which the trolley runs. Jib Metal lattice that pivots on the tower and lifts and extends the hoisting system. Hoisting rope Durable cable of variable length for manipulating loads. Hoisting block System of pulleys that work with the trolley pulley to improve leverage to lift heavy loads. OCCUPATIONAL SAFETY (OSH

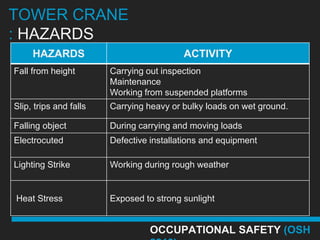

- 8. TOWER CRANE : HAZARDS HAZARDS ACTIVITY Fall from height Carrying out inspection Maintenance Working from suspended platforms Slip, trips and falls Carrying heavy or bulky loads on wet ground. Falling object During carrying and moving loads Electrocuted Defective installations and equipment Lighting Strike Working during rough weather Heat Stress Exposed to strong sunlight OCCUPATIONAL SAFETY (OSH

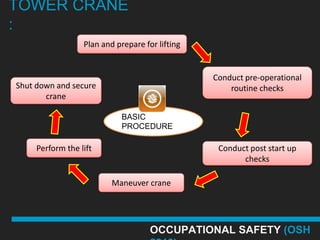

- 9. TOWER CRANE : Plan and prepare for lifting Conduct pre-operational Shut down and secure routine checks crane BASIC PROCEDURE Perform the lift Conduct post start up checks Maneuver crane OCCUPATIONAL SAFETY (OSH

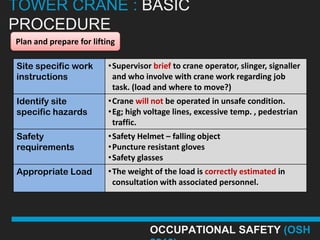

- 10. TOWER CRANE : BASIC PROCEDURE Plan and prepare for lifting Site specific work •Supervisor brief to crane operator, slinger, signaller instructions and who involve with crane work regarding job task. (load and where to move?) Identify site •Crane will not be operated in unsafe condition. specific hazards •Eg; high voltage lines, excessive temp. , pedestrian traffic. Safety •Safety Helmet – falling object requirements •Puncture resistant gloves •Safety glasses Appropriate Load •The weight of the load is correctly estimated in consultation with associated personnel. OCCUPATIONAL SAFETY (OSH

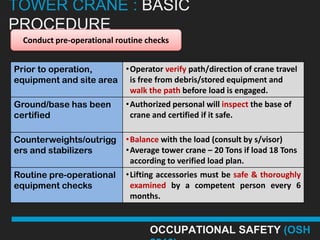

- 11. TOWER CRANE : BASIC PROCEDURE Conduct pre-operational routine checks Prior to operation, •Operator verify path/direction of crane travel equipment and site area is free from debris/stored equipment and walk the path before load is engaged. Ground/base has been •Authorized personal will inspect the base of certified crane and certified if it safe. Counterweights/outrigg •Balance with the load (consult by s/visor) ers and stabilizers •Average tower crane – 20 Tons if load 18 Tons according to verified load plan. Routine pre-operational •Lifting accessories must be safe & thoroughly equipment checks examined by a competent person every 6 months. OCCUPATIONAL SAFETY (OSH

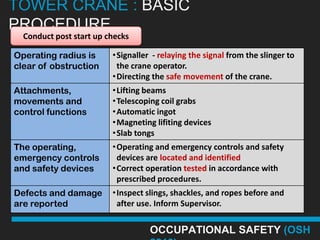

- 12. TOWER CRANE : BASIC PROCEDURE Conduct post start up checks Operating radius is •Signaller - relaying the signal from the slinger to clear of obstruction the crane operator. •Directing the safe movement of the crane. Attachments, •Lifting beams movements and •Telescoping coil grabs control functions •Automatic ingot •Magneting lifiting devices •Slab tongs The operating, •Operating and emergency controls and safety emergency controls devices are located and identified and safety devices •Correct operation tested in accordance with prescribed procedures. Defects and damage •Inspect slings, shackles, and ropes before and are reported after use. Inform Supervisor. OCCUPATIONAL SAFETY (OSH

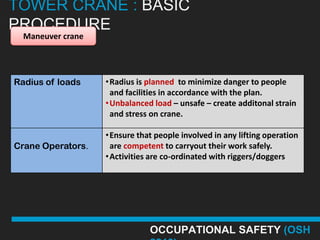

- 13. TOWER CRANE : BASIC PROCEDURE Maneuver crane Radius of loads •Radius is planned to minimize danger to people and facilities in accordance with the plan. •Unbalanced load – unsafe – create additonal strain and stress on crane. •Ensure that people involved in any lifting operation Crane Operators. are competent to carryout their work safely. •Activities are co-ordinated with riggers/doggers OCCUPATIONAL SAFETY (OSH

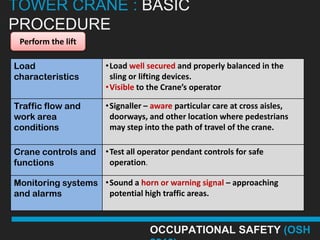

- 14. TOWER CRANE : BASIC PROCEDURE Perform the lift Load •Load well secured and properly balanced in the characteristics sling or lifting devices. •Visible to the Crane’s operator Traffic flow and •Signaller – aware particular care at cross aisles, work area doorways, and other location where pedestrians conditions may step into the path of travel of the crane. Crane controls and •Test all operator pendant controls for safe functions operation. Monitoring systems •Sound a horn or warning signal – approaching and alarms potential high traffic areas. OCCUPATIONAL SAFETY (OSH

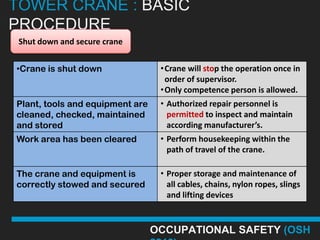

- 15. TOWER CRANE : BASIC PROCEDURE Shut down and secure crane •Crane is shut down •Crane will stop the operation once in order of supervisor. •Only competence person is allowed. Plant, tools and equipment are • Authorized repair personnel is cleaned, checked, maintained permitted to inspect and maintain and stored according manufacturer’s. Work area has been cleared • Perform housekeeping within the path of travel of the crane. The crane and equipment is • Proper storage and maintenance of correctly stowed and secured all cables, chains, nylon ropes, slings and lifting devices OCCUPATIONAL SAFETY (OSH

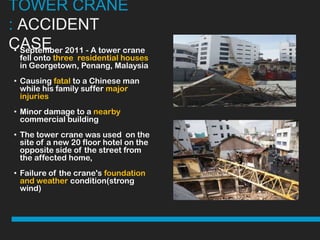

- 16. TOWER CRANE : ACCIDENT CASE 2011 - A tower crane • September fell onto three residential houses in Georgetown, Penang, Malaysia • Causing fatal to a Chinese man while his family suffer major injuries • Minor damage to a nearby commercial building • The tower crane was used on the site of a new 20 floor hotel on the opposite side of the street from the affected home, • Failure of the crane's foundation and weather condition(strong wind)

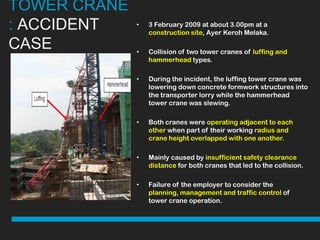

- 17. TOWER CRANE : ACCIDENT • 3 February 2009 at about 3.00pm at a construction site, Ayer Keroh Melaka. CASE • Collision of two tower cranes of luffing and hammerhead types. • During the incident, the luffing tower crane was lowering down concrete formwork structures into the transporter lorry while the hammerhead tower crane was slewing. • Both cranes were operating adjacent to each other when part of their working radius and crane height overlapped with one another. • Mainly caused by insufficient safety clearance distance for both cranes that led to the collision. • Failure of the employer to consider the planning, management and traffic control of tower crane operation.