Tpm&oee

- 1. TOTAL PRODUCTIVE MAINTENANCE (TPM) 11/2/2015 AJEET SINGH DHAMA 1

- 2. Total Productive Maintenance is also Known As TPM ? Basically TPM is very Important Programme of Maintenance As well As Whole Plant. ? It works on Eight pillars ? Every Pillars are very Important for all the Plant ? It was discovered by Mr. Sakichi Toyoda , Of Toyota Motors ? It was improved By JIPM (Japanese institute of Plant Maintenance) ? It works on Eight Pillars & Six SubPillars , on TPM works 11/2/2015 AJEET SINGH DHAMA 2

- 3. EIGHT PILLARS OF TPM ? Following are the Eight pillars of TPM :- 1. Kobetsu Kaizen (Individual Improvement) 2. Jishu Hozen (Autonomous Maintenance) 3. Planned Maintenance (PM) 4. Quality Maintenance (QM) 5. Education & Training (E&T) 6. Development Management (DM) 7. Saftey Health & Environment (SHE) 8. Office TPM (OTPM) 11/2/2015 AJEET SINGH DHAMA 3

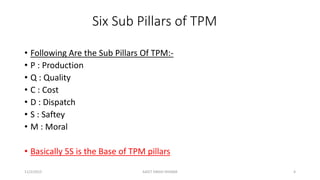

- 4. Six Sub Pillars of TPM ? Following Are the Sub Pillars Of TPM:- ? P : Production ? Q : Quality ? C : Cost ? D : Dispatch ? S : Saftey ? M : Moral ? Basically 5S is the Base of TPM pillars 11/2/2015 AJEET SINGH DHAMA 4

- 5. Goals Of TPM:- ? Prevention of Breakdown & Failures ? It increase life of Equipment ? Reduces Failure & Breakdowns ? Reduces Costly Down Time ? Decrease Cost Of Replacement TPM is Maintenance Programme Concept 11/2/2015 AJEET SINGH DHAMA 5

- 6. Types Of Maintenance :- ? Preventive Maintenance ( PM ) – Greasing , Oil , Filters ? Predictive Maintenance ( PdM ) – Inspections ? Corrective Maintenance (CM) - Repairs TPM Evolved from TQM which evolved as a direct result TPM is the foundation for JITFA , Poke Yoke , Lean Manufacturing & Zero Defects Rules of TPM :- Zero Defects Zero Accidents Zero Failures 11/2/2015 AJEET SINGH DHAMA 6

- 7. Over All Equipement Efficiency :- ? Formula of OEE :- OEE = A x P x Q Where :- A : Availability P : Performance Q : Quality 11/2/2015 AJEET SINGH DHAMA 7

- 8. 7 QC Tools :- Most Important for all ? 7 QC Tools are : ? Check Sheet ? Pareto Diagram ? Cause & Effect Diagram ? Graph & Control Charts ? Histogram ? Startification ? Scatter Diagram 11/2/2015 AJEET SINGH DHAMA 8

- 9. Practice TPM To Attain Our Goals:- ? Increase in Asset Utilization & Equipment OEE. ? Faster Production Equipment Ownership ? Equipment Breakdown Prevention ? Evolving in to self directed work terms & Lean Manufacturing 11/2/2015 AJEET SINGH DHAMA 9

- 10. Japanese Standard for Press Shop :- Points to be Check in Press Machine in Press shop :- 1. 狠狠撸 2. Bolster Plate 3. Two Hand Operation Button 4. Photoelectric Saftey Device (PhotoCell Sensor) 5. SIT-III Where : SIT-III :- Servo Press Control System 11/2/2015 AJEET SINGH DHAMA 10