Training for Production Management regarding the basic line management procedure

- 1. Production Floor Management Training Session - 1

- 3. The very basic responsibility for every Operations Personnel: 1. Entering the factory at least 10-15 minutes before line starting. (6:45-6:50 AM) 2. Conducting Morning Meeting with all the operators. 3. Completing Morning meeting at least 5 minutes before line starting. (6:55 AM) 4. Starting the whole line at sharp 7:00 AM. 5. End of the day organizing respective zone/line/floor for tomorrowŌĆÖs operation with proper housekeeping and 5S.

- 4. Are we really following this?

- 5. Scenario 1: More than 50% operators are still sitting around at 7:06 (Date- 19- November-2022)

- 6. Scenario 2: Empty Workstations after 7:10 AM

- 7. Scenario 3: Line hasnŌĆÖt started even at 7:09 AM.

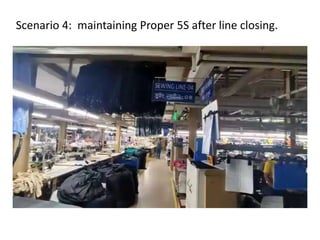

- 8. Scenario 4: maintaining Proper 5S after line closing.

- 9. How to be A good Line Management?

- 10. 1. Achieving Hourly Target with good quality each hour based on available capacity. Why we are failing here? A. Lack of initiative by Line Managements to identify and analyze bottlenecks. Escalating 90% problem to next level leaders. B. Lack of teamwork between Line chief, supervisors and Quality Supervisors to solve repetitive quality problems. C. Not having the ŌĆ£ Wining as a TEAMŌĆØ mindset in the Line Level and Zone Level Teams. (Production, Quality, IE, Maintenance and Technical) D. Lack of control over own team member as a team leader. E. Lack of respect of for each other, companyŌĆÖs SOP and basic disciplines.

- 11. 2. Achieving 1st three hour Production target Why we are failing here? What can we do better? A. Forecasting list of probable absenteeism in the next few days and making a plan for that with the help of Line IE, Zone APM and PM. B. Motivating the team members to take leave instead of absenteeism C. Incase of any sudden absenteeism zone supervisor has to communicate with his seniors and IE and sit on that process until IE allocate operator for that process. D. Making sure the output area isnŌĆÖt dried out the next day by ensuring the available capacity from each workstation, every hour. E. Achieving the previous day target within the planned hours. *All Absenteeism issue has to be solved within 15 minutes. (Line IE and Zone APM)

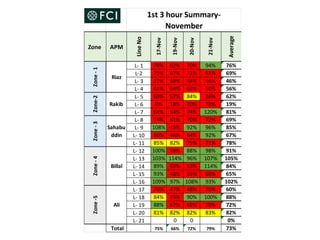

- 12. Zone APM Line No 17-Nov 19-Nov 20-Nov 21-Nov Average L- 1 78% 62% 70% 94% 76% L-2 75% 67% 71% 61% 69% L- 3 27% 68% 44% 46% 46% L- 4 41% 64% 68% 50% 56% L- 5 60% 67% 84% 36% 62% L- 6 0% 18% 20% 38% 19% L- 7 64% 64% 74% 120% 81% L- 8 74% 61% 70% 72% 69% L- 9 108% 45% 92% 96% 85% L- 10 66% 46% 64% 92% 67% L- 11 85% 82% 75% 71% 78% L- 12 100% 78% 88% 98% 91% L- 13 103% 114% 96% 107% 105% L- 14 89% 69% 63% 114% 84% L- 15 93% 48% 59% 60% 65% L- 16 109% 97% 108% 93% 102% L- 17 76% 47% 48% 70% 60% L- 18 84% 79% 90% 100% 88% L- 19 88% 67% 65% 70% 72% L- 20 81% 82% 82% 83% 82% L- 21 0 0 0% Total 75% 66% 72% 79% 73% 1st 3 hour Summary- November Zone - 4 Zone -5 Ali Billal Zone - 3 Sahabu ddin Zone - 1 Riaz Zone-2 Rakib

- 13. 3. Achieving First Day Efficiency by following QCO Need to achieve first day efficiency by doing my part to ensure successful implementation QCO procedure. Why we are failing here? A. Not finishing previous styles on time. Mainly due to rejection, recut and defect repairing delay. B. Lack of production follow up in the backside area. C. Failure to provide pre-trained operator to Specific processes due to unplanned absenteeism and leave. D. Lack of involvement during feeding time following the CompanyŌĆÖs Changeover Standard Procedure.

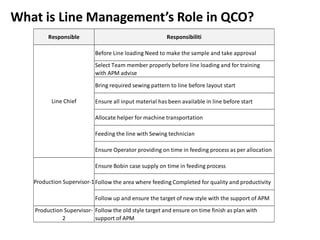

- 14. What is Line ManagementŌĆÖs Role in QCO? Responsible Responsibiliti Before Line loading Need to make the sample and take approval Select Team member properly before line loading and for training with APM advise Bring required sewing pattern to line before layout start Ensure all input material has been available in line before start Allocate helper for machine transportation Feeding the line with Sewing technician Ensure Operator providing on time in feeding process as per allocation Ensure Bobin case supply on time in feeding process Follow the area where feeding Completed for quality and productivity Follow up and ensure the target of new style with the support of APM Production Supervisor- 2 Follow the old style target and ensure on time finish as plan with support of APM Line Chief Production Supervisor-1

- 15. ŌĆóEach Zone APM need to Lead the Changeover with the Zone Technician and IE. ŌĆóZone APM need to make sure his line management is performing his respective role in the changeover.

- 16. Single Piece flow Benefits and Mechanism

- 17. Why Single Piece Flow is Better 1. Better FTT% 2. Better P2P% by solving problems hidden in the system for long time. 3. Faster response to any kind of problem from the support team 4. Better housekeeping and safety and workforce morale.

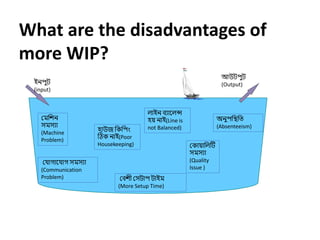

- 18. What are the disadvantages of more WIP? Ó”ćÓ”©Ó”¬Ó¦üÓ”¤ (input) Ó”åÓ”ēÓ”¤Ó”¬Ó¦üÓ”¤ (Output) Ó”«Ó¦ćÓ”ČÓ”┐Ó”© Ó”ĖÓ¦ćÓ”ĖÓ”»Ó”Š (Machine Problem) Ó”╣Ó”ŠÓ”ēÓ”£ Ó”ČÓ”┐Ó”ČÓ”¬Ó”┐Ó”é Ó”ĀÓ”┐Ó”┐ Ó”©Ó”ŠÓ”ć(Poor Housekeeping) Ó”▓Ó”ŠÓ”ćÓ”© Ó”¼Ó¦ŹÓ”»Ó”ŠÓ”▓Ó”▓Ó”©Ó¦ŹÓ”Ė Ó”╣Ó¦¤ Ó”©Ó”ŠÓ”ć(Line is not Balanced) Ó”ģÓ”©Ó¦üÓ”¬Ó”ČÓ”┐Ó”ČÓ”┐ (Absenteeism) Ó”«Ó”┐Ó”ŠÓ¦¤Ó”ŠÓ”ČÓ”▓Ó”ĀÓ”¤ Ó”ĖÓ¦ćÓ”ĖÓ”»Ó”Š (Quality Issue ) Ó”« Ó”ŠÓ”ŚÓ”ŠÓ”▓ Ó”ŠÓ”Ś Ó”ĖÓ¦ćÓ”ĖÓ”»Ó”Š (Communication Problem) Ó”«Ó”¼Ó¦ŹÓ”┐Ó¦Ć Ó”«Ó”ĖÓ”¤Ó”ŠÓ”¬ Ó”¤Ó”ŠÓ”ćÓ¦ć (More Setup Time)

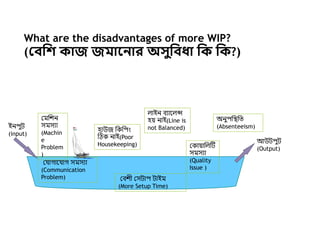

- 19. What are the disadvantages of more WIP? (Ó”¼Ó¦ćÓ”ČÓ”┐ Ó”ĢÓ”ŠÓ”£ Ó”£Ó”«Ó”ŠÓ”© Ó”ŠÓ”░ Ó”ģÓ”ĖÓ¦üÓ”ČÓ¦ćÓ”¦Ó”Š Ó”ČÓ”Ģ Ó”ČÓ”Ģ?) Ó”ćÓ”©Ó”¬Ó¦üÓ”¤ (input) Ó”åÓ”ēÓ”¤Ó”¬Ó¦üÓ”¤ (Output) Ó”«Ó¦ćÓ”ČÓ”┐Ó”© Ó”ĖÓ¦ćÓ”ĖÓ”»Ó”Š (Machin e Problem ) Ó”╣Ó”ŠÓ”ēÓ”£ Ó”ČÓ”┐Ó”ČÓ”¬Ó”┐Ó”é Ó”ĀÓ”┐Ó”┐ Ó”©Ó”ŠÓ”ć(Poor Housekeeping) Ó”▓Ó”ŠÓ”ćÓ”© Ó”¼Ó¦ŹÓ”»Ó”ŠÓ”▓Ó”▓Ó”©Ó¦ŹÓ”Ė Ó”╣Ó¦¤ Ó”©Ó”ŠÓ”ć(Line is not Balanced) Ó”ģÓ”©Ó¦üÓ”¬Ó”ČÓ”┐Ó”ČÓ”┐ (Absenteeism) Ó”«Ó”┐Ó”ŠÓ¦¤Ó”ŠÓ”ČÓ”▓Ó”ĀÓ”¤ Ó”ĖÓ¦ćÓ”ĖÓ”»Ó”Š (Quality Issue ) Ó”« Ó”ŠÓ”ŚÓ”ŠÓ”▓ Ó”ŠÓ”Ś Ó”ĖÓ¦ćÓ”ĖÓ”»Ó”Š (Communication Problem) Ó”«Ó”¼Ó¦ŹÓ”┐Ó¦Ć Ó”«Ó”ĖÓ”¤Ó”ŠÓ”¬ Ó”¤Ó”ŠÓ”ćÓ¦ć (More Setup Time)

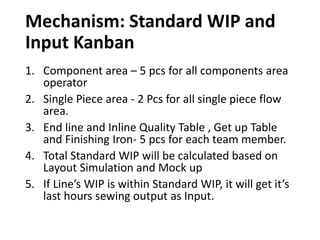

- 20. Mechanism: Standard WIP and Input Kanban 1. Component area ŌĆō 5 pcs for all components area operator 2. Single Piece area - 2 Pcs for all single piece flow area. 3. End line and Inline Quality Table , Get up Table and Finishing Iron- 5 pcs for each team member. 4. Total Standard WIP will be calculated based on Layout Simulation and Mock up 5. If LineŌĆÖs WIP is within Standard WIP, it will get itŌĆÖs last hours sewing output as Input.

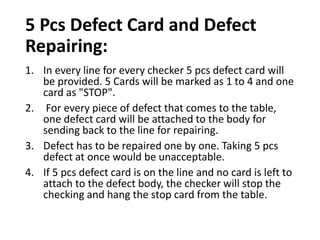

- 21. 5 Pcs Defect Card and Defect Repairing: 1. In every line for every checker 5 pcs defect card will be provided. 5 Cards will be marked as 1 to 4 and one card as "STOP". 2. For every piece of defect that comes to the table, one defect card will be attached to the body for sending back to the line for repairing. 3. Defect has to be repaired one by one. Taking 5 pcs defect at once would be unacceptable. 4. If 5 pcs defect card is on the line and no card is left to attach to the defect body, the checker will stop the checking and hang the stop card from the table.

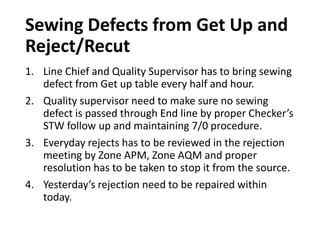

- 23. Sewing Defects from Get Up and Reject/Recut 1. Line Chief and Quality Supervisor has to bring sewing defect from Get up table every half and hour. 2. Quality supervisor need to make sure no sewing defect is passed through End line by proper CheckerŌĆÖs STW follow up and maintaining 7/0 procedure. 3. Everyday rejects has to be reviewed in the rejection meeting by Zone APM, Zone AQM and proper resolution has to be taken to stop it from the source. 4. YesterdayŌĆÖs rejection need to be repaired within today.

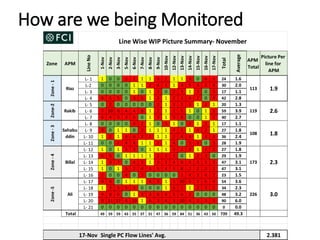

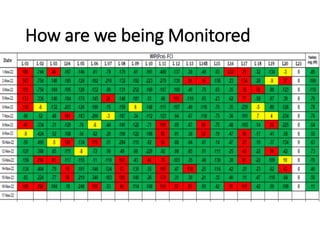

- 24. How are we being Monitored Zone APM Line No 1-Nov 2-Nov 3-Nov 5-Nov 6-Nov 7-Nov 8-Nov 9-Nov 10-Nov 12-Nov 13-Nov 14-Nov 15-Nov 16-Nov 17-Nov Total Average APM Total Picture Per line for APM L- 1 1 0 0 2 2 1 1 3 2 1 1 3 0 4 3 24 1.6 L-2 0 0 0 0 1 1 2 4 3 1 4 5 3 2 4 30 2.0 L- 3 0 0 0 0 1 0 1 3 0 2 3 1 3 0 3 17 1.1 L- 4 4 5 5 0 3 5 1 3 1 2 3 4 2 0 4 42 2.8 L- 5 0 2 0 0 0 0 0 2 1 3 5 3 1 2 1 20 1.3 L- 6 7 10 8 4 4 8 1 2 1 2 5 1 0 1 5 59 3.9 L- 7 4 4 5 3 5 0 1 3 1 3 8 0 0 1 2 40 2.7 L- 8 0 0 0 0 4 2 1 0 3 1 0 2 1 2 1 17 1.1 L- 9 3 0 1 1 0 2 1 1 1 4 5 1 4 2 1 27 1.8 L- 10 1 2 1 4 6 2 2 1 1 2 4 3 1 3 3 36 2.4 L- 11 0 0 2 4 4 1 1 2 1 4 0 3 3 0 3 28 1.9 L- 12 1 0 1 5 3 0 1 1 1 3 2 3 1 2 3 27 1.8 L- 13 6 5 0 1 1 1 1 2 3 3 0 1 2 3 0 29 1.9 L- 14 1 3 7 0 4 3 1 3 3 4 6 3 3 3 3 47 3.1 L- 15 1 0 1 5 2 4 3 5 4 5 8 2 2 2 3 47 3.1 L- 16 2 0 0 4 0 2 0 0 0 0 2 4 3 4 2 23 1.5 L- 17 4 6 0 1 1 1 4 3 1 5 10 5 3 6 4 54 3.6 L- 18 1 3 5 5 3 0 0 0 1 6 2 1 2 3 2 34 2.3 L- 19 4 8 6 0 1 3 3 6 4 5 6 2 0 0 0 48 3.2 L- 20 9 11 17 4 10 1 6 3 4 3 10 4 2 3 3 90 6.0 L- 21 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.0 Total 49 59 59 43 55 37 31 47 36 59 84 51 36 43 50 739 49.3 2.381 17-Nov Single PC Flow Lines' Avg. Line Wise WIP Picture Summary- November 226 173 Zone - 4 3.0 Zone -5 Ali Billal 2.3 108 119 Zone - 3 Sahabu ddin 1.8 113 1.9 2.6 Zone - 1 Riaz Zone-2 Rakib

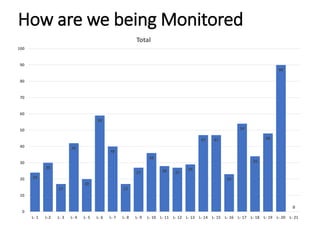

- 25. How are we being Monitored 24 30 17 42 20 59 40 17 27 36 28 27 29 47 47 23 54 34 48 90 0 0 10 20 30 40 50 60 70 80 90 100 L- 1 L-2 L- 3 L- 4 L- 5 L- 6 L- 7 L- 8 L- 9 L- 10 L- 11 L- 12 L- 13 L- 14 L- 15 L- 16 L- 17 L- 18 L- 19 L- 20 L- 21 Total

- 26. How are we being Monitored

- 27. How to Sustain Single Piece flow?

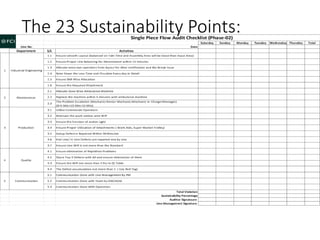

- 28. The 23 Sustainability Points:

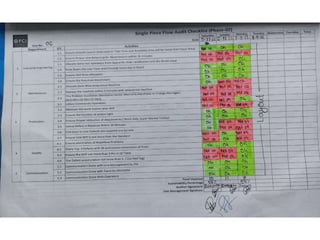

- 29. Proper Monitoring of the Sustainability Points is the key

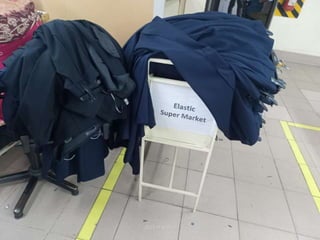

- 32. Rule : 1: Everything needs to be kept in their designated places.

- 37. Rule No: 2: Before leaving the factory make sure the line/Zone is organized for the next day

- 39. Last but not Least 1. The SOPŌĆÖs and Standards are there for a reason. 2. We are here to manage our juniors. We are not here to get managed by them.

- 40. Thank You