Tuan's Resume

- 1. Objective + To be an assistant manager in two years + To be a manager in next one year after Education HCM University of IT and Foreign Languages (2005 > 2009) Bachelor of English Skills 1. Proficiency in English, Chinese to be in level of communication 2. Computer literacy 3. SAP literacy Personal Character Enthusiastic and open minded, optimistic, a good sense of humor and well- interacting with people of all ages and all walks of life. Experience Administrator ¨C Trinity Center (2010 > 2011) + Prepare learning materials for students and keep track on class information + Support as Teaching Assistant + Consult for studentˇŻs problem in their study Production Supervisor ¨C Foster Electric Company (2011 > 2012) + Base on shipment/required to evaluate production line capacity and head count + Project simulation on line capacity and head count as demand upturns + Plan and issue daily, monthly production schedule + Align with Purchasing to confirm materials readiness to build requested plan + Work with others department for defected goods (work with QA, QC for sorting criteria and headcount) + Follow hourly/daily/monthly output as to catch up the demand + Calculate on tooling capacity to meet injection capacity + Align with production for requisition of inter site demand and commit their requested deadline + Follow escalation path if root cause persists (Continued) Name: PHUNG XUONG TUAN Phone: 0906.993.087 Email: phungxuongtuan.pxt@gmail.com Address: 109 Do Huu Vi, Lai Thieu, Binh Duong Hobbies Reading, travelling with family and friends, sports (gym and swimming)

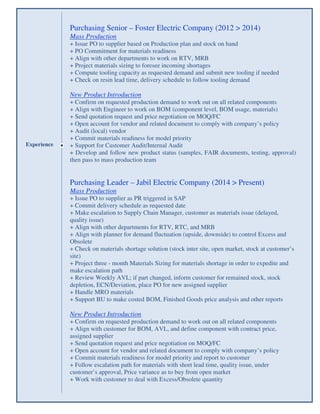

- 2. Experience Purchasing Senior ¨C Foster Electric Company (2012 > 2014) Mass Production + Issue PO to supplier based on Production plan and stock on hand + PO Commitment for materials readiness + Align with other departments to work on RTV, MRB + Project materials sizing to foresee incoming shortages + Compute tooling capacity as requested demand and submit new tooling if needed + Check on resin lead time, delivery schedule to follow tooling demand New Product Introduction + Confirm on requested production demand to work out on all related components + Align with Engineer to work on BOM (component level, BOM usage, materials) + Send quotation request and price negotiation on MOQ/FC + Open account for vendor and related document to comply with companyˇŻs policy + Audit (local) vendor + Commit materials readiness for model priority + Support for Customer Audit/Internal Audit + Develop and follow new product status (samples, FAIR documents, testing, approval) then pass to mass production team Purchasing Leader ¨C Jabil Electric Company (2014 > Present) Mass Production + Issue PO to supplier as PR triggered in SAP + Commit delivery schedule as requested date + Make escalation to Supply Chain Manager, customer as materials issue (delayed, quality issue) + Align with other departments for RTV, RTC, and MRB + Align with planner for demand fluctuation (upside, downside) to control Excess and Obsolete + Check on materials shortage solution (stock inter site, open market, stock at customerˇŻs site) + Project three - month Materials Sizing for materials shortage in order to expedite and make escalation path + Review Weekly AVL; if part changed, inform customer for remained stock, stock depletion, ECN/Deviation, place PO for new assigned supplier + Handle MRO materials + Support BU to make costed BOM, Finished Goods price analysis and other reports New Product Introduction + Confirm on requested production demand to work out on all related components + Align with customer for BOM, AVL, and define component with contract price, assigned supplier + Send quotation request and price negotiation on MOQ/FC + Open account for vendor and related document to comply with companyˇŻs policy + Commit materials readiness for model priority and report to customer + Follow escalation path for materials with short lead time, quality issue, under customerˇŻs approval, Price variance as to buy from open market + Work with customer to deal with Excess/Obsolete quantity