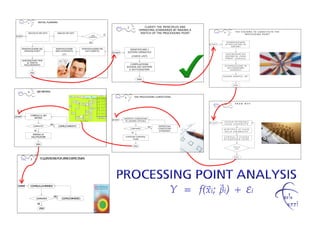

Tuzzi wcm flow PPA it

- 1. 1 INITIAL PLANNING 2 CLARIFY THE PRINCIPLES AND OPERATING STANDARDS BY MAKING A 3 T H E S Y S T E M S T O C O N S T IT U T E T H E RACCOLTA DEI DATI ANALISI DEI DATI SKETCH OF THE PROCESSING POINT P R O C E S S IN G P O IN T SONO SI START AGGREGATI? NO S C O M P O S IZ IO N E START A T T R E Z Z A T U R A IN S IS T E M I IDENTIFICAZIONE DEL IDENTIFICAZIONE STRATIFICAZIONE DEI IDENTIFICARE I ŌĆ×PROCESS POINTŌĆØ AREA INTERVENTO DATI (PARETO) START SISTEMI OPERATIVI (ZT) D E S C R IZ IO N E D E I (CHECK LIST) S IS T E M I IN ŌĆ×C O S A F A N N O ŌĆØ (G E N E R IC O ) ASSEGNAZIONE TEMA AL TEAM DI MIGLIORAMENTO COMPILAZIONE S C O M P O S IZ IO N E IN SCHEDA DEI SISTEMI S O T T O S IS T E M I E SOTTOSISTEMI (G E N E R IC O ) END S C H E M A G R A F IC O ŌĆ×P P ŌĆØ END END 6 QM MATRIX Inspection item Q Process control item Machine characteristics Section M Characteristics Check Large Medium Small 5 THE PROCESSING CONDITIONS Screw Clearance clearance Rubber ŌĆó Mooney property ŌĆó Hardness No Motor K N O W- W H Y ŌĆó Foreign r.p.m. vibration rotation 4 substances Output Bank quantity: Rubbe quantity constant r for Hot water supply extruder supply Rubber thickness quantity Bank Temperature 60 Ōäā Temperature quantity of hot water constant Cutter Feed width position Machine Feed Mandrel characteristics thickness thickness COMPILA IL QM Roller START Crown crown Crown Roller shape quantity MATRIX Diameter: 0.25 VERIFICA CONDIZIONI Offset: 5/1000 Degree of influence Roller Offset START Roller shape quantity clearance Fig. 6.12 MQ analysis DI LAVORO ATTUALI S T U D IO P O T E N Z IA L I S T A R T NO C A U S E V A R IA B IL IT A ŌĆÖ COMPLETO? COMPLETAMENTO NO RIPRISTINO CONFORMI? CONDIZIONI ID E N T IF IC A L E C A U S E SI STANDARD D E L L A V A R IA B IL IT A ŌĆÖ SI ESEGUI LA VALUTAZIONE STESURA CONTROL C O M P IL A L A S C H E D A PLAN D I R IE P IL O G O C A U S E END END C H E C K LIS T E N D 7 5 Q ES N FO Z O D U TIO S R ER EFEC ES TIV S R TA T C M O PILA LA M TR E A IC NO C M O PLETO? C M O PLETA EN M TO SI END