Types of impellers

- 1. TYPES OF IMPELLERS PRESENTED BY :-RUSHIKESH KALE GUIDED BY :-PROF.SHODHAN MAYEKAR

- 2. CONTENT ïIntroduction ïClassification ïOpen type ïPartially open ïClosed type ïImpeller in Washing machine ïReferences

- 3. INTRODUCTION âĒ An impeller is a rotating component of a centrifugal pump, usually made of iron, steel, bronze, brass, aluminum, rubber or plastic, which transfers energy from the motor that drives the pump to the fluid being pumped by accelerating the fluid outwards from the center of rotation. âĒ An impeller is a rotating component of a centrifugal pump which transfers energy from the motor that drives the pump to the fluid being pumped by accelerating the fluid outwards from the center of rotation. The velocity achieved by the impeller transfers into pressure when the outward movement of the fluid is confined by the pump casing. Impellers are usually short cylinders with an open inlet (called an eye) to accept incoming fluid, vanes to push the fluid radially, and a splined, keyed, or threaded bore to accept a drive-shaft. âĒ The impeller made out of cast material in many cases may be called rotor, also. It is cheaper to cast the radial impeller right in the support it is fitted on, which is put in motion by the gearbox from an electric motor, combustion engine or by steam driven turbine. The rotor usually names both the spindle and the impeller when they are mounted by bolts.

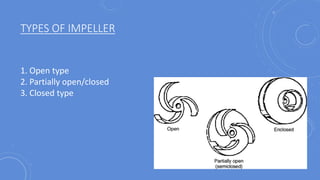

- 4. TYPES OF IMPELLER 1. Open type 2. Partially open/closed 3. Closed type

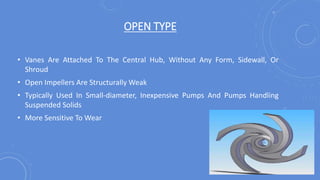

- 5. OPEN TYPE âĒ Vanes Are Attached To The Central Hub, Without Any Form, Sidewall, Or Shroud âĒ Open Impellers Are Structurally Weak âĒ Typically Used In Small-diameter, Inexpensive Pumps And Pumps Handling Suspended Solids âĒ More Sensitive To Wear

- 6. PARTIALLY OPEN OR SEMICLOSED IMPELLERS âĒ Incorporates A Back Wall (Shroud) âĒ Used In Medium-diameter Pumps And With Liquids Containing Small Amounts Of Suspended Solids âĒ They Offer Higher Efficiencies And Lower NPSHR Than Open Impellers âĒ Small Clearance Or Gap Exists Between The Impeller Vanes And The Housing

- 7. CLOSED IMPELLERS âĒ The Closed Impeller Has Both A Back And Front Wall For Maximum Strength âĒ High Efficiencies And Low NPSHR âĒ They Can Operate In Suspended-solids Service Without Clogging But Will Exhibit High Wear Rates âĒ Wear Rings On The Impeller And On The Pump Housing

- 8. IMPELLER IN WASHING MACHINE âĒ Some constructions of top loading washing machines use impellers to agitate the laundry during washing. âĒ An agitator is a device or mechanism to put something into motion by shaking or stirring .

- 9. REFERENCES 1. https://en.wikipedia.org/wiki/Agitator_(device) 2. Impeller- OED , March 2013. Oxford University edition (page 207) 3. www.nuclear-power.net/nuclear-engineering/fluid.../impeller-types-of- impellers