Ultrasonic Machining (USM)

Download as PPT, PDF34 likes9,893 views

Ultrasonic machining uses a vibrating tool at ultrasonic frequencies to machine hard, brittle materials with little heat generation. It works by using an abrasive slurry between the tool and workpiece. The process allows machining of non-conductive materials that cannot be cut via other methods. It produces burr-free surfaces but has low material removal rates and high tool wear. Applications include machining ceramics, semiconductors, glass, and other hard materials, as well as drilling small, deep holes without damaging surrounding structures.

1 of 16

Downloaded 1,150 times

Recommended

Water jet machining

Water jet machiningVarun Garg

Ã˝

Water jet machining uses a high-pressure stream of water to cut materials. It is a cold cutting process that produces no heat-affected zones. The water jet travels at supersonic speeds and erodes material when the local pressure exceeds the material's strength. Key components include a hydraulic pump to pressurize water, an intensifier to further pressurize it, and a nozzle to direct the jet. It can cut a variety of materials and offers advantages over other cutting methods like reduced burrs, flexibility of cutting complex shapes, and not producing heat or fumes. However, it is not suitable for high-volume production.Electro Chemical Machining Process

Electro Chemical Machining ProcessD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

Electrochemical machining (ECM) is a non-traditional machining process that removes metal by electrolysis rather than mechanical forces. In ECM, a tool acts as a cathode and the workpiece as an anode, and an electric current is passed through an electrolyte in the gap between them, chemically dissolving metal from the workpiece. ECM can machine hard metals and complex shapes more accurately than traditional machining. It provides a smooth surface finish with no mechanical forces or heat affecting the workpiece material. However, ECM requires an electrolyte solution, specialized equipment, and produces chemical waste, making it more expensive and less environmentally friendly than other processes.Various Non-conventional machining Process

Various Non-conventional machining Processaman1312

Ã˝

The document provides information on various non-conventional machining processes. It begins by defining non-traditional manufacturing processes as those that remove material using mechanical, thermal, electrical, or chemical energy without sharp cutting tools. Extremely hard materials are difficult to machine with traditional processes. The document then discusses several non-traditional processes in detail, including abrasive jet machining (AJM), ultrasonic machining (USM), electrical discharge machining (EDM), and their working principles and applications.Ultrasonic machining process (USM)

Ultrasonic machining process (USM)Yuga Aravind Kumar

Ã˝

Ultrasonic machining (USM) is a mechanical process that uses high frequency vibrations and an abrasive slurry to erode fine holes and cavities in hard or brittle materials. It is well-suited for machining brittle materials like glass, ceramics, and semiconductors. The material removal occurs through abrasion by the particles in the slurry, with no thermal or chemical changes to the workpiece. USM produces intricate shapes and profiles with good surface finish and integrity.Electron Beam machining

Electron Beam machiningD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

Electron beam machining (EBM) uses a focused beam of electrons to melt and vaporize small amounts of material. It was invented in 1952 and works by accelerating electrons in a vacuum chamber to generate a small, high-energy spot that precisely removes material through melting and vaporization. Key aspects of EBM include its ability to machine very small, high aspect ratio holes and its minimal heat affected zone. However, it requires expensive equipment and vacuum conditions.Wire cut EDM

Wire cut EDMDhruv Shah

Ã˝

Wire cut EDM uses a thin wire as the electrode to cut complex shapes into difficult-to-machine materials like tungsten carbide. The process involves using a CNC machine to move the workpiece near the vertically moving wire while a dielectric fluid flows between them. Electrical sparks erode small amounts of material from both the wire and workpiece, with the fluid flushing away debris. Key aspects that enable the precision process include a servo system to maintain a small gap, water-based dielectric fluid for initiating sparks and cooling, and characteristics of the consumable wire electrode.Electrical Discharge Machining Process

Electrical Discharge Machining ProcessD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

The material removal in EDM occurs due to the formation and collapse of plasma channels between the tool and workpiece. When a potential difference is applied, electrons are emitted from the tool and strike the workpiece, generating heat and forming craters. The main components of an EDM system are a power supply, workpiece and tool made of conductive materials, a dielectric medium like kerosene or water, and a servo control unit. Process parameters like voltage, current, pulse duration, and spark gap influence the material removal rate and surface finish. EDM can machine hard metals and complex shapes that other methods have difficulty with.Hybrid machining

Hybrid machiningShankha Goswami

Ã˝

Hybrid manufacturing combines two or more non-traditional manufacturing processes. Electrochemical grinding combines electrochemical machining and grinding. It uses a grinding wheel and electrolytic fluid to remove material from a conductive workpiece. The process produces close tolerances and smooth surfaces. Key advantages are minimal wheel wear and ability to machine hard materials. Applications include machining difficult materials like carbides and composites. Future developments could improve efficiency and surface quality when machining advanced materials.Electric Discharge machining Process

Electric Discharge machining ProcessAniket Joshi

Ã˝

Electric Discharge machining Process, MSBTE, Diloma, Mechanical, Engineering, Final Year, Advanced Manufacturing Processes, Fifth Semester, Dielectric, ECM : Electrochemical machining - Principle,process,subsystems & applications

ECM : Electrochemical machining - Principle,process,subsystems & applicationsPratik Chaudhari

Ã˝

ECM : Electrochemical machining - Principle,process,subsystems & applications. Specialized processes under ECM.Edm

EdmAlok Yadav

Ã˝

This document presents information on electric discharge machining (EDM). EDM is a manufacturing process that uses electrical sparks to remove material from a workpiece to shape it. In EDM, an electrode is brought close to the workpiece submerged in a dielectric fluid, causing sparks that erode away material. EDM can machine very hard materials, complex shapes, and delicate parts without physical contact or pressure. It is useful for dies, molds, aerospace parts, and electronics due to these advantages, though it has slow material removal rates and can be an electrical hazard.Abrasive water jet machining

Abrasive water jet machiningmohit99033

Ã˝

Abrasive water jet machining (AWJM) is a non-traditional machining process that uses a high-pressure stream of water mixed with abrasive particles to erode materials. It works by converting the kinetic energy of the water-abrasive jet into high pressure upon impacting the workpiece surface, removing material when the pressure exceeds the part's strength. The document discusses the AWJM process, including its mechanism of localized erosion, key parameters like water pressure and abrasive flow rate, applications in cutting a wide range of materials, advantages like flexibility and lack of heat, and limitations for hard or thick materials.Abrasive flow machining (afm)

Abrasive flow machining (afm)sagar agarwal

Ã˝

Abrasive flow machining is a finishing process that uses a semi-solid abrasive putty to remove small amounts of material from workpieces. The putty is forced through or across the workpiece using hydraulic pressure to deburr, radius, polish and perform other surface finishing operations. It is well suited for finishing metals, ceramics and plastics in a uniform and economical manner, though it is not used for heavy material removal due to its low material removal rate. The process involves selecting abrasive media based on the material and desired finish, and using tooling and pressure to direct the flow of media through restrictions in the workpiece.Chemical machining

Chemical machiningHareesha N Gowda, Dayananda Sagar College of Engg, Bangalore

Ã˝

This presentation gives an information about introduction to Chemical machining covering the syllabus of Non Traditional Machining.Laser Beam machining Process

Laser Beam machining ProcessD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

This document discusses laser beam machining (LBM), including:

- How lasers work by generating coherent, monochromatic light through stimulated emission.

- Common laser mediums like ruby, Nd:YAG, CO2, and their wavelengths.

- How laser light interacts with materials through absorption, melting, and vaporization.

- Key LBM process parameters like intensity, interaction time, and material properties.

- Applications of LBM like drilling, cutting, welding, and micro-machining.Plasma Arc Machining

Plasma Arc MachiningRajnish Bhusal

Ã˝

This document discusses plasma arc machining (PAM). PAM uses a high-velocity jet of heated gas at around 50,000°C to melt and remove material. Gases are ionized to form plasma which is directed at the workpiece. Key components of PAM systems include a plasma gun, power supply, and cooling mechanisms. PAM can machine hard metals and is used for applications like tube milling, welding specialty alloys, and nuclear pipe systems. Advantages are high production rates and ability to machine hard metals, while disadvantages include high initial costs and inefficient for large cavities. Various PAM types are also described such as conventional, air, and dual-flow systems.Magnestic abrasive finishing process

Magnestic abrasive finishing processrahul lokhande

Ã˝

SSC 10th result 2016, check Online 10th Maharashtra result 2016, ssc online results maharashtra 2016, HSC result 2016 electrochemical grinding

electrochemical grinding boney191

Ã˝

1. Electrochemical grinding (ECG) is a non-traditional machining process that removes electrically conductive material by grinding with a negatively charged abrasive wheel, electrolyte fluid, and a positively charged workpiece. Materials are removed through electrolysis and some abrasion, leaving a smooth burr-free surface.

2. ECG can machine very hard and brittle materials more effectively than traditional processes due to generating little heat. Key parameters that affect the material removal rate include the abrasive wheel properties, workpiece material and surface, machining conditions, electrolyte type and properties, and voltage applied.

3. ECG provides advantages like burr-free surfaces, less work hardening, higher precisionElectrical discharge machining [EDM]![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

Electrical discharge machining [EDM]Dhruv Shah

Ã˝

Electrical discharge machining (EDM) is an unconventional machining process that uses electrical sparks to erode unwanted material from a workpiece by discharging electricity between an electrode tool and the workpiece, separated by a dielectric fluid. EDM can machine hard materials and complex shapes by using individual sparks that briefly heat the material to plasma temperatures without direct contact. The process works by concentrating electrons and ions in the dielectric fluid gap between the tool and workpiece, causing sparks that thermally erode unwanted material. EDM enables precision machining of difficult shapes for aerospace and medical applications but has low material removal rates and leaves a rough surface finish.Electrical discharge machining

Electrical discharge machining Gopinath Guru

Ã˝

The document provides information on Electrical Discharge Machining (EDM). EDM is a manufacturing process where electrical discharges are used to erode material from a workpiece to achieve a desired shape. In EDM, a series of sparks erode material by rapidly recurring electrical discharges between two electrodes separated by a dielectric liquid and subject to an electric voltage. One electrode is the tool that shapes the workpiece. Material removal occurs through thermal melting and vaporization caused by the extreme heat of electrical sparks between the electrodes.Electrical discharge machining

Electrical discharge machiningAsha A

Ã˝

The document discusses Electrical Discharge Machining (EDM). EDM is a manufacturing process where a desired shape is obtained by removing material from a workpiece using electrical discharges between two electrodes separated by a dielectric liquid. As the distance between the electrodes is reduced, current flows due to dielectric breakdown causing material removal from both electrodes. EDM was invented in the 1940s and has since improved, increasing machining speeds and reducing costs. EDM can machine hard metals and intricate shapes without needing to soften the material. The main components of an EDM system are the power supply, dielectric medium, workpiece and tool electrodes, and servo control unit. Material is removed through the formation and collapse of plasma channels between the electrodes duringElectrochemical Machining (ECM)

Electrochemical Machining (ECM)RAVI KUMAR

Ã˝

Electrochemical Machining (ECM) has established itself as one of the major alternatives to conventional methods of machining difficult - to - cut materials of and generating complex contours, without inducing residual stress and tool wear.

This seminar is devoted to the study of influences of variable ECM parameters like applied voltage and feed rate keeping other parameters constant on the surface roughness (Ra) using Response Surface Methodology (RSM).

Plasma Arc Machining process

Plasma Arc Machining processD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

Plasma arc machining uses ionized gas (plasma) to cut metals. It can cut materials that are difficult to cut with traditional techniques due to high thermal conductivity and oxidation resistance. The process involves generating a pilot arc to ignite the plasma and transferring the arc to the workpiece to melt and vaporize the metal, which is removed by the high-velocity gas. Plasma arc machining produces high-quality cuts at maximum productivity and is suitable for automated cutting applications.Advantages and limitation of non traditional machining

Advantages and limitation of non traditional machiningMrunal Mohadikar

Ã˝

The document provides an overview of several non-traditional machining processes including Electrical Discharge Machining (EDM), Electrochemical Machining (ECM), Ultrasonic Machining (USM), Laser Beam Machining (LBM), Water Jet Cutting, and Abrasive Water Jet Cutting. For each process, the document discusses the basic technique, key advantages such as ability to machine hard materials and produce complex shapes, and limitations such as low material removal rates or inability to machine non-conductive materials. The document serves to educate readers on alternative manufacturing methods beyond traditional cutting tools and their various applications and constraints.Usm g.venkatesh

Usm g.venkateshGANGISETTY VENKATESH

Ã˝

Ultrasonic machining (USM) involves removing material from a workpiece using high-frequency vibrations and an abrasive slurry. Key components of USM include a generator, transducer, horn, tool, abrasive slurry, and workpiece. The main material removal mechanisms are mechanical abrasion, impact, erosion, and chemical effects. USM can machine hard and brittle materials like ceramics and has advantages like avoiding thermal/mechanical damage but has limitations like lower material removal rates compared to other processes. Process parameters that influence the material removal rate include amplitude, frequency, abrasive size, and slurry properties.Abrasive water jet machining

Abrasive water jet machiningAkhil Kumar

Ã˝

This document provides an overview of abrasive water jet machining (AWJM). It begins with an introduction that defines AWJM as a non-traditional machining process that uses the mechanical energy of water and abrasives for material removal. The working principle and basic mechanism of material removal are then described. Key aspects of AWJM equipment and processes are discussed, including the pumping system, abrasive feed system, nozzle, process parameters like water pressure and abrasive flow rate, and applications of the technique. Advantages include the ability to machine many materials without thermal damage but disadvantages include relatively low machining speeds.Unit 4 chemical and electrochemical energy based processes

Unit 4 chemical and electrochemical energy based processesNarayanasamy Pandiarajan

Ã˝

This document discusses various chemical and electrochemical machining processes. It describes chemical machining (CHM) which uses chemical etching to remove material from a workpiece. It involves using etchants and maskants to selectively remove material. Electrochemical machining (ECM) uses electrolysis principles to remove material from a workpiece submerged in an electrolyte solution. Variations include electrochemical grinding (ECG) which combines ECM with conventional grinding, and electrochemical honing (ECH) which uses non-conductive honing stones instead of a grinding wheel. These processes allow burr-free machining of complex shapes in hard and brittle materials with good surface finish and accuracy.1408285

1408285Pankaj Athawali

Ã˝

This document discusses ultrasonic machining. It begins by defining ultrasonic machining as a process that uses a vibrating tool at ultrasonic frequencies along with an abrasive slurry to machine materials. It then describes the main parts of an ultrasonic machining system and provides an overview of how the process works. The document outlines some key advantages of ultrasonic machining, such as its ability to machine hard, brittle materials without generating significant heat, and lists some disadvantages like low material removal rates. Finally, it provides several examples of applications for ultrasonic machining in industries like dentistry, electronics, and aerospace.Ultrasonic machining

Ultrasonic machiningjani parth

Ã˝

This document provides an overview of ultrasonic machining including its history, key parts, working principle, advantages, disadvantages, and applications. Ultrasonic machining uses ultrasonic vibrations and an abrasive slurry to machine hard, brittle materials without causing damage from heat. It has advantages like being able to machine non-conductive materials and producing burr-free parts. However, it has low material removal rates and requires tooling that wears from the abrasive particles. Ultrasonic machining is used for applications like machining ceramics, cutting industrial diamonds, and drilling dental cavities without pain.More Related Content

What's hot (20)

Electric Discharge machining Process

Electric Discharge machining ProcessAniket Joshi

Ã˝

Electric Discharge machining Process, MSBTE, Diloma, Mechanical, Engineering, Final Year, Advanced Manufacturing Processes, Fifth Semester, Dielectric, ECM : Electrochemical machining - Principle,process,subsystems & applications

ECM : Electrochemical machining - Principle,process,subsystems & applicationsPratik Chaudhari

Ã˝

ECM : Electrochemical machining - Principle,process,subsystems & applications. Specialized processes under ECM.Edm

EdmAlok Yadav

Ã˝

This document presents information on electric discharge machining (EDM). EDM is a manufacturing process that uses electrical sparks to remove material from a workpiece to shape it. In EDM, an electrode is brought close to the workpiece submerged in a dielectric fluid, causing sparks that erode away material. EDM can machine very hard materials, complex shapes, and delicate parts without physical contact or pressure. It is useful for dies, molds, aerospace parts, and electronics due to these advantages, though it has slow material removal rates and can be an electrical hazard.Abrasive water jet machining

Abrasive water jet machiningmohit99033

Ã˝

Abrasive water jet machining (AWJM) is a non-traditional machining process that uses a high-pressure stream of water mixed with abrasive particles to erode materials. It works by converting the kinetic energy of the water-abrasive jet into high pressure upon impacting the workpiece surface, removing material when the pressure exceeds the part's strength. The document discusses the AWJM process, including its mechanism of localized erosion, key parameters like water pressure and abrasive flow rate, applications in cutting a wide range of materials, advantages like flexibility and lack of heat, and limitations for hard or thick materials.Abrasive flow machining (afm)

Abrasive flow machining (afm)sagar agarwal

Ã˝

Abrasive flow machining is a finishing process that uses a semi-solid abrasive putty to remove small amounts of material from workpieces. The putty is forced through or across the workpiece using hydraulic pressure to deburr, radius, polish and perform other surface finishing operations. It is well suited for finishing metals, ceramics and plastics in a uniform and economical manner, though it is not used for heavy material removal due to its low material removal rate. The process involves selecting abrasive media based on the material and desired finish, and using tooling and pressure to direct the flow of media through restrictions in the workpiece.Chemical machining

Chemical machiningHareesha N Gowda, Dayananda Sagar College of Engg, Bangalore

Ã˝

This presentation gives an information about introduction to Chemical machining covering the syllabus of Non Traditional Machining.Laser Beam machining Process

Laser Beam machining ProcessD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

This document discusses laser beam machining (LBM), including:

- How lasers work by generating coherent, monochromatic light through stimulated emission.

- Common laser mediums like ruby, Nd:YAG, CO2, and their wavelengths.

- How laser light interacts with materials through absorption, melting, and vaporization.

- Key LBM process parameters like intensity, interaction time, and material properties.

- Applications of LBM like drilling, cutting, welding, and micro-machining.Plasma Arc Machining

Plasma Arc MachiningRajnish Bhusal

Ã˝

This document discusses plasma arc machining (PAM). PAM uses a high-velocity jet of heated gas at around 50,000°C to melt and remove material. Gases are ionized to form plasma which is directed at the workpiece. Key components of PAM systems include a plasma gun, power supply, and cooling mechanisms. PAM can machine hard metals and is used for applications like tube milling, welding specialty alloys, and nuclear pipe systems. Advantages are high production rates and ability to machine hard metals, while disadvantages include high initial costs and inefficient for large cavities. Various PAM types are also described such as conventional, air, and dual-flow systems.Magnestic abrasive finishing process

Magnestic abrasive finishing processrahul lokhande

Ã˝

SSC 10th result 2016, check Online 10th Maharashtra result 2016, ssc online results maharashtra 2016, HSC result 2016 electrochemical grinding

electrochemical grinding boney191

Ã˝

1. Electrochemical grinding (ECG) is a non-traditional machining process that removes electrically conductive material by grinding with a negatively charged abrasive wheel, electrolyte fluid, and a positively charged workpiece. Materials are removed through electrolysis and some abrasion, leaving a smooth burr-free surface.

2. ECG can machine very hard and brittle materials more effectively than traditional processes due to generating little heat. Key parameters that affect the material removal rate include the abrasive wheel properties, workpiece material and surface, machining conditions, electrolyte type and properties, and voltage applied.

3. ECG provides advantages like burr-free surfaces, less work hardening, higher precisionElectrical discharge machining [EDM]![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

![Electrical discharge machining [EDM]](https://cdn.slidesharecdn.com/ss_thumbnails/electricaldischargemachiningedm-170803232011-thumbnail.jpg?width=560&fit=bounds)

Electrical discharge machining [EDM]Dhruv Shah

Ã˝

Electrical discharge machining (EDM) is an unconventional machining process that uses electrical sparks to erode unwanted material from a workpiece by discharging electricity between an electrode tool and the workpiece, separated by a dielectric fluid. EDM can machine hard materials and complex shapes by using individual sparks that briefly heat the material to plasma temperatures without direct contact. The process works by concentrating electrons and ions in the dielectric fluid gap between the tool and workpiece, causing sparks that thermally erode unwanted material. EDM enables precision machining of difficult shapes for aerospace and medical applications but has low material removal rates and leaves a rough surface finish.Electrical discharge machining

Electrical discharge machining Gopinath Guru

Ã˝

The document provides information on Electrical Discharge Machining (EDM). EDM is a manufacturing process where electrical discharges are used to erode material from a workpiece to achieve a desired shape. In EDM, a series of sparks erode material by rapidly recurring electrical discharges between two electrodes separated by a dielectric liquid and subject to an electric voltage. One electrode is the tool that shapes the workpiece. Material removal occurs through thermal melting and vaporization caused by the extreme heat of electrical sparks between the electrodes.Electrical discharge machining

Electrical discharge machiningAsha A

Ã˝

The document discusses Electrical Discharge Machining (EDM). EDM is a manufacturing process where a desired shape is obtained by removing material from a workpiece using electrical discharges between two electrodes separated by a dielectric liquid. As the distance between the electrodes is reduced, current flows due to dielectric breakdown causing material removal from both electrodes. EDM was invented in the 1940s and has since improved, increasing machining speeds and reducing costs. EDM can machine hard metals and intricate shapes without needing to soften the material. The main components of an EDM system are the power supply, dielectric medium, workpiece and tool electrodes, and servo control unit. Material is removed through the formation and collapse of plasma channels between the electrodes duringElectrochemical Machining (ECM)

Electrochemical Machining (ECM)RAVI KUMAR

Ã˝

Electrochemical Machining (ECM) has established itself as one of the major alternatives to conventional methods of machining difficult - to - cut materials of and generating complex contours, without inducing residual stress and tool wear.

This seminar is devoted to the study of influences of variable ECM parameters like applied voltage and feed rate keeping other parameters constant on the surface roughness (Ra) using Response Surface Methodology (RSM).

Plasma Arc Machining process

Plasma Arc Machining processD. Palani Kumar / Kamaraj College of Engineering & Technology

Ã˝

Plasma arc machining uses ionized gas (plasma) to cut metals. It can cut materials that are difficult to cut with traditional techniques due to high thermal conductivity and oxidation resistance. The process involves generating a pilot arc to ignite the plasma and transferring the arc to the workpiece to melt and vaporize the metal, which is removed by the high-velocity gas. Plasma arc machining produces high-quality cuts at maximum productivity and is suitable for automated cutting applications.Advantages and limitation of non traditional machining

Advantages and limitation of non traditional machiningMrunal Mohadikar

Ã˝

The document provides an overview of several non-traditional machining processes including Electrical Discharge Machining (EDM), Electrochemical Machining (ECM), Ultrasonic Machining (USM), Laser Beam Machining (LBM), Water Jet Cutting, and Abrasive Water Jet Cutting. For each process, the document discusses the basic technique, key advantages such as ability to machine hard materials and produce complex shapes, and limitations such as low material removal rates or inability to machine non-conductive materials. The document serves to educate readers on alternative manufacturing methods beyond traditional cutting tools and their various applications and constraints.Usm g.venkatesh

Usm g.venkateshGANGISETTY VENKATESH

Ã˝

Ultrasonic machining (USM) involves removing material from a workpiece using high-frequency vibrations and an abrasive slurry. Key components of USM include a generator, transducer, horn, tool, abrasive slurry, and workpiece. The main material removal mechanisms are mechanical abrasion, impact, erosion, and chemical effects. USM can machine hard and brittle materials like ceramics and has advantages like avoiding thermal/mechanical damage but has limitations like lower material removal rates compared to other processes. Process parameters that influence the material removal rate include amplitude, frequency, abrasive size, and slurry properties.Abrasive water jet machining

Abrasive water jet machiningAkhil Kumar

Ã˝

This document provides an overview of abrasive water jet machining (AWJM). It begins with an introduction that defines AWJM as a non-traditional machining process that uses the mechanical energy of water and abrasives for material removal. The working principle and basic mechanism of material removal are then described. Key aspects of AWJM equipment and processes are discussed, including the pumping system, abrasive feed system, nozzle, process parameters like water pressure and abrasive flow rate, and applications of the technique. Advantages include the ability to machine many materials without thermal damage but disadvantages include relatively low machining speeds.Unit 4 chemical and electrochemical energy based processes

Unit 4 chemical and electrochemical energy based processesNarayanasamy Pandiarajan

Ã˝

This document discusses various chemical and electrochemical machining processes. It describes chemical machining (CHM) which uses chemical etching to remove material from a workpiece. It involves using etchants and maskants to selectively remove material. Electrochemical machining (ECM) uses electrolysis principles to remove material from a workpiece submerged in an electrolyte solution. Variations include electrochemical grinding (ECG) which combines ECM with conventional grinding, and electrochemical honing (ECH) which uses non-conductive honing stones instead of a grinding wheel. These processes allow burr-free machining of complex shapes in hard and brittle materials with good surface finish and accuracy.Similar to Ultrasonic Machining (USM) (20)

1408285

1408285Pankaj Athawali

Ã˝

This document discusses ultrasonic machining. It begins by defining ultrasonic machining as a process that uses a vibrating tool at ultrasonic frequencies along with an abrasive slurry to machine materials. It then describes the main parts of an ultrasonic machining system and provides an overview of how the process works. The document outlines some key advantages of ultrasonic machining, such as its ability to machine hard, brittle materials without generating significant heat, and lists some disadvantages like low material removal rates. Finally, it provides several examples of applications for ultrasonic machining in industries like dentistry, electronics, and aerospace.Ultrasonic machining

Ultrasonic machiningjani parth

Ã˝

This document provides an overview of ultrasonic machining including its history, key parts, working principle, advantages, disadvantages, and applications. Ultrasonic machining uses ultrasonic vibrations and an abrasive slurry to machine hard, brittle materials without causing damage from heat. It has advantages like being able to machine non-conductive materials and producing burr-free parts. However, it has low material removal rates and requires tooling that wears from the abrasive particles. Ultrasonic machining is used for applications like machining ceramics, cutting industrial diamonds, and drilling dental cavities without pain.Ultrasonic Machining.pptx

Ultrasonic Machining.pptxROHITH KUMAR

Ã˝

This document discusses ultrasonic machining (USM), an unconventional machining process used to machine hard and brittle materials. USM uses a vibrating tool and abrasive slurry to erode material from the workpiece. It can machine materials harder than 40 HRC like ceramics and carbides that cannot be conventionally machined. USM produces precision features with a smooth surface finish without causing heat damage. While it has a high initial cost and low material removal rate, USM is useful for machining difficult materials like glass, ceramics, and carbides that are used in applications like wire drawing dies, dental drills, and cutting diamonds.Ultrasonic Machining(USM)

Ultrasonic Machining(USM)BISHAL DAS

Ã˝

This document provides an overview of ultrasonic machining (USM). It describes the working principles of USM, including that it uses a vibrating tool and abrasive slurry to erode material. The key components of a USM system are also outlined, including the generator, transducer, tool, and abrasive slurry. Some advantages of USM are its ability to machine brittle materials without thermal damage and produce complex shapes. Limitations include lower material removal rates compared to other processes and ineffective slurry circulation at deeper hole depths. USM has applications in machining hard materials like ceramics and semiconductors.Ultrasonic machining

Ultrasonic machiningParag Priyank

Ã˝

Ultrasonic machining uses a vibrating tool oscillating at ultrasonic frequencies to remove material from a workpiece with an abrasive slurry between them. Very little heat is produced since the tool never contacts the workpiece. This makes it suitable for hard, brittle materials like ceramics. The presentation discusses the process elements of work material, tool cone and tip, and abrasive slurry. It explains that hard, brittle materials can be machined and abrasives like boron carbide are commonly used. The tool design considerations are to resist fatigue failure while providing the proper stroke and mass.Ultrasonic Machining (USM)

Ultrasonic Machining (USM)Amlan Talukdar

Ã˝

Ultrasonic machining (USM) is a subtractive assembling measure that eliminates material from the outer layer of a section through high frequency , low amplitude vibrations of a tool against the material surface within the sight of fine rough particles.

USM is most normally used to machining of glass, ceramics, zirconia, valuable stones, and solidified prepares. USM permits the cutting of perplexing and non-uniform shape with very high accuracy.Ultra sonic machining

Ultra sonic machiningAnkit Singla

Ã˝

Ultrasonic machining is a non-traditional machining process that uses high-frequency vibrations and abrasive slurry to remove material. It is well-suited for hard and brittle materials. The document describes the process, including that a vibrating tool and abrasive slurry are used to induce micro-cracks and fracture material removed. Applications include machining tungsten carbide, diamond, glass, and other hard materials that are difficult to machine with traditional methods.ultrasonic maching

ultrasonic machingMann Harr

Ã˝

Ultrasonic machining is a non-traditional machining process that uses high-frequency ultrasonic vibrations to remove material. Piezoelectric or magnetostrictive transducers convert electrical energy into high-frequency mechanical vibrations, causing a tool to chip away tiny pieces of the workpiece material through abrasion with abrasive slurry. This allows for machining very hard and brittle materials like ceramics, glass, and carbides. Common applications include drilling, grinding, and profiling of brittle materials where traditional machining cannot be used.Chapter 3 usm

Chapter 3 usmBachrun ashar

Ã˝

Ultrasonic machining adalah alat non konvensional dengan menggunakan metode frekuensi suara ultrasonicChapter 3 usm

Chapter 3 usmVaralakshmi Kothuru

Ã˝

Ultrasonic machining is a non-traditional machining process that uses abrasive particles in a slurry to machine hard and brittle materials. In the process, a tool oscillates at ultrasonic frequencies (19-25 kHz) with an amplitude of 15-50 microns over the workpiece while being flooded with an abrasive slurry. Material is removed through crack initiation and brittle fracture as the abrasive particles indent the workpiece material. Ultrasonic machining can machine materials that are too hard for conventional machining or that cannot be processed through EDM or ECM due to being non-conductive. Key components of ultrasonic machining equipment include a generator, transducer, toolELECTRICAL_DISCHARGE_MACHINING.pptx

ELECTRICAL_DISCHARGE_MACHINING.pptxshreedharsb1

Ã˝

Electrical discharge machining (EDM) is a machining method typically used for hard metals which are electrically conductive. It makes it possible to work with metals for which traditional machining techniques are ineffective. EDM can machine very complex shapes, very hard materials, and do so with high accuracy due to the lack of physical contact between the tool and workpiece. However, EDM has lower material removal rates compared to traditional cutting and involves additional time and costs for electrode creation.Class29 nontraditional+machining

Class29 nontraditional+machiningglmech61

Ã˝

The document discusses various non-traditional machining processes including chemical machining, electrochemical machining, electrical discharge machining, laser beam machining, electron beam machining, water jet machining, abrasive jet machining, and ultrasonic machining. These processes are used for hard materials, complex shapes, or where heat and stresses from traditional machining would cause damage. Each process removes material in unique ways such as through chemical dissolution, electrochemical erosion, electrical sparks, focused light/electron beams, or abrasive particle impact.ELECTRICAL_DISCHARGE_MACHINING.pptx

ELECTRICAL_DISCHARGE_MACHINING.pptxAtanuJana21

Ã˝

Electrical discharge machining (EDM) is a machining method typically used for hard metals which are electrically conductive. It makes it possible to work with metals that cannot be machined through traditional methods. EDM uses electrical sparks to erode away metal and can machine very hard materials, complex geometries, and delicate parts that other methods cannot. While it enables machining difficult materials, EDM has disadvantages like slow material removal rates and high power consumption compared to traditional machining.Non-Conventional Machining

Non-Conventional Machiningjitender kundu

Ã˝

This document provides an introduction to non-conventional machining processes. It discusses how these processes use indirect energy like sparks, lasers, heat, or chemicals rather than direct contact between a tool and workpiece. Some key non-conventional machining processes described include electrical discharge machining, wire EDM, laser beam machining, electron beam machining, water jet machining, abrasive jet machining, ultrasonic machining, electrochemical machining, and electrochemical grinding. Advantages of these processes include high accuracy, less wear, longer tool life, and reduced environmental hazards compared to conventional machining.Advantages and disadvantages of Ultrasonic Machining by Himanshu Vaid

Advantages and disadvantages of Ultrasonic Machining by Himanshu VaidHimanshu Vaid

Ã˝

Ultrasonic machining uses high-frequency vibrations delivered to a tool tip embedded in an abrasive slurry to machine hard, brittle materials without generating heat. It can produce intricate shapes in materials like ceramics, glass, and silicon. Some advantages are that it machines without applying pressure, produces little heat or stress, and can cut complex shapes. However, it also has low material removal rates, requires skilled operators, and the tools wear more quickly than in other machining methods.Electrical Discharge machining

Electrical Discharge machiningAnish jha

Ã˝

Electrical discharge machining (EDM) is a machining process that uses electrical sparks to erode hard metals. It was developed in the mid-1970s and allows machining of materials that are difficult to cut with traditional tools. EDM works by using electrical sparks between an electrode and workpiece submerged in dielectric fluid to erode away material. It can machine complex shapes with high accuracy in hard metals and is often used for molds, dies, and prototypes. While EDM enables machining hard materials, the process is relatively slow compared to traditional cutting.Ultrasonic Machining for mechanical engineering

Ultrasonic Machining for mechanical engineeringIrfanAli932082

Ã˝

Ultrasonic Machining for mechanical Engineering U5 p1 ntm processes

U5 p1 ntm processesgautam buddha university

Ã˝

This document discusses nontraditional manufacturing processes. It provides an overview of ultrasonic machining (USM), describing the process, material removal mechanism, advantages, disadvantages, and applications. It also summarizes waterjet machining (WJM) and abrasive waterjet machining (AWJM), explaining the principles, advantages, disadvantages, and applications of these processes. Finally, it briefly introduces abrasive jet machining (AJM), describing the basic process and its uses.U5 p1 ntm processes

U5 p1 ntm processesgautam buddha university

Ã˝

This document discusses nontraditional manufacturing processes. It provides an overview of ultrasonic machining (USM), describing the process, material removal mechanism, advantages, disadvantages, and applications. It also summarizes waterjet machining (WJM) and abrasive waterjet machining (AWJM), explaining the principles, advantages, disadvantages, and applications of these processes. Finally, it briefly introduces abrasive jet machining (AJM), describing the basic process and its uses.Nonconventional machining

Nonconventional machiningrushikesh urunkar

Ã˝

this topic comes under manufacturing engineering or particularly machine tools.it gives brief information on non conventional machining which includes total six no of machines.Recently uploaded (20)

How to Build a Maze Solving Robot Using Arduino

How to Build a Maze Solving Robot Using ArduinoCircuitDigest

Ã˝

Learn how to make an Arduino-powered robot that can navigate mazes on its own using IR sensors and "Hand on the wall" algorithm.

This step-by-step guide will show you how to build your own maze-solving robot using Arduino UNO, three IR sensors, and basic components that you can easily find in your local electronics shop.Water Industry Process Automation & Control Monthly - March 2025.pdf

Water Industry Process Automation & Control Monthly - March 2025.pdfWater Industry Process Automation & Control

Ã˝

Welcome to the March 2025 issue of WIPAC Monthly the magazine brought to you by the LinkedIn Group WIPAC Monthly.

In this month's edition, on top of the month's news from the water industry we cover subjects from the intelligent use of wastewater networks, the use of machine learning in water quality as well as how, we as an industry, need to develop the skills base in developing areas such as Machine Learning and Artificial Intelligence.

Enjoy the latest editionTurbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

Ã˝

High Efficiency Chiller System in HVACLecture -3 Cold water supply system.pptx

Lecture -3 Cold water supply system.pptxrabiaatif2

Ã˝

The presentation on Cold Water Supply explored the fundamental principles of water distribution in buildings. It covered sources of cold water, including municipal supply, wells, and rainwater harvesting. Key components such as storage tanks, pipes, valves, and pumps were discussed for efficient water delivery. Various distribution systems, including direct and indirect supply methods, were analyzed for residential and commercial applications. The presentation emphasized water quality, pressure regulation, and contamination prevention. Common issues like pipe corrosion, leaks, and pressure drops were addressed along with maintenance strategies. Diagrams and case studies illustrated system layouts and best practices for optimal performance.How to Make an RFID Door Lock System using Arduino

How to Make an RFID Door Lock System using ArduinoCircuitDigest

Ã˝

Learn how to build an RFID-based door lock system using Arduino to enhance security with contactless access control.Best KNow Hydrogen Fuel Production in the World The cost in USD kwh for H2

Best KNow Hydrogen Fuel Production in the World The cost in USD kwh for H2Daniel Donatelli

Ã˝

The cost in USD/kwh for H2

Daniel Donatelli

Secure Supplies Group

Index

• Introduction - Page 3

• The Need for Hydrogen Fueling - Page 5

• Pure H2 Fueling Technology - Page 7

• Blend Gas Fueling: A Transition Strategy - Page 10

• Performance Metrics: H2 vs. Fossil Fuels - Page 12

• Cost Analysis and Economic Viability - Page 15

• Innovations Driving Leadership - Page 18

• Laminar Flame Speed Adjustment

• Heat Management Systems

• The Donatelli Cycle

• Non-Carnot Cycle Applications

• Case Studies and Real-World Applications - Page 22

• Conclusion: Secure Supplies’ Leadership in Hydrogen Fueling - Page 27

Env and Water Supply Engg._Dr. Hasan.pdf

Env and Water Supply Engg._Dr. Hasan.pdfMahmudHasan747870

Ã˝

Core course, namely Environment and Water Supply Engineering. Full lecture notes are in book format for the BSc in Civil Engineering program. Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

Ã˝

Kalite Politikamız

Taykon Çelik için kalite, hayallerinizi bizlerle paylaştığınız an başlar. Proje çiziminden detayların çözümüne, detayların çözümünden üretime, üretimden montaja, montajdan teslime hayallerinizin gerçekleştiğini gördüğünüz ana kadar geçen tüm aşamaları, çalışanları, tüm teknik donanım ve çevreyi içine alır KALİTE.Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptx

Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptxppkmurthy2006

Ã˝

Mathematics behind machine learning INT255 15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdf

15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdfNgocThang9

Ã˝

Smart Cities Big Data, Civic Hackers, and the Quest for a New UtopiaIntroduction to Safety, Health & Environment

Introduction to Safety, Health & Environmentssuserc606c7

Ã˝

Introduction to

Safety, Health &EnvironmentOptimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

Ã˝

Optimal use of resources, including energy, is one of the most important principles in modern and sustainable agricultural systems. Exergy analysis and life cycle assessment were used to study the efficient use of inputs, energy consumption reduction, and various environmental effects in the corn production system in Lorestan province, Iran. The required data were collected from farmers in Lorestan province using random sampling. The Cobb-Douglas equation and data envelopment analysis were utilized for modeling and optimizing cumulative energy and exergy consumption (CEnC and CExC) and devising strategies to mitigate the environmental impacts of corn production. The Cobb-Douglas equation results revealed that electricity, diesel fuel, and N-fertilizer were the major contributors to CExC in the corn production system. According to the Data Envelopment Analysis (DEA) results, the average efficiency of all farms in terms of CExC was 94.7% in the CCR model and 97.8% in the BCC model. Furthermore, the results indicated that there was excessive consumption of inputs, particularly potassium and phosphate fertilizers. By adopting more suitable methods based on DEA of efficient farmers, it was possible to save 6.47, 10.42, 7.40, 13.32, 31.29, 3.25, and 6.78% in the exergy consumption of diesel fuel, electricity, machinery, chemical fertilizers, biocides, seeds, and irrigation, respectively. Water Industry Process Automation & Control Monthly - March 2025.pdf

Water Industry Process Automation & Control Monthly - March 2025.pdfWater Industry Process Automation & Control

Ã˝

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

Ã˝

Ultrasonic Machining (USM)

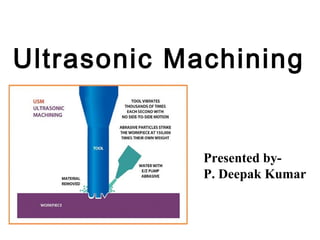

- 1. Ultrasonic Machining Presented by- P. Deepak Kumar

- 3. Introduction ÔÉòAlso Known as Ultrasonic Impact Grinding. ÔÉòVibrating tool at ultrasonic frequency. ÔÉòUse of abrasive slurry. ÔÉòVery little heat generated.

- 5. Working

- 7. Advantages ÔÉò It can be used machine hard, brittle, fragile and non conductive material. ÔÉò No heat is generated in work, therefore no significant changes in physical structure of work material.

- 8. ÔÉò Non-metal (because of the poor electrical conductivity) that cannot be machined by EDM and ECM can very well be machined by USM. ÔÉò It is burr less and distortion less processes. ÔÉò It can be adopted in conjunction with other new technologies like EDM,ECG,ECM.

- 9. Disadvantages ÔÉò Low Metal removal rate. ÔÉò It is difficult to drill deep holes, as slurry movement is restricted.

- 10. ÔÉòTool wear rate is high due to abrasive particles. Tools made from brass, tungsten carbide, MS or tool steel will wear from the action of abrasive grit with a ratio that ranges from 1:1 to 200:1. ÔÉòUSM can be used only when the hardness of work is more than 45 HRC.

- 11. Applications ÔÉò Machining of cavities in electrically non- conductive ceramics ÔÉò Used to machine fragile components in which otherwise the scrap rate is high ÔÉò Used for multistep processing for fabricating silicon nitride (Si3N4) turbine blades

- 12. ÔÉò Used for machining hard, brittle metallic alloys, semiconductors, glass, ceramics, carbides etc. ÔÉò Used for machining round, square, irregular shaped holes and surface impressions. ÔÉò Used in machining of dies for wire drawing, punching and blanking operations

- 13. ÔÉò USM has been used for piercing of dies and for parting off and blanking operations. ÔÉò USM enables a dentist to drill a hole of any shape on teeth without any pain. ÔÉò Ferrites and steel parts , precision mineral stones can be machined using USM

- 14. ÔÉòUSM can be used to cut industrial diamonds ÔÉòUSM is used for grinding Quartz, Glass, ceramics ÔÉòCutting holes with curved or spiral centre lines and cutting threads in glass and mineral or metallo-ceramics

- 15. ÔÉòUSM can perform machining operations like drilling, grinding and milling operations on all materials which can be treated suitably with abrasives. ÔÉòLarge number of holes of small diameter. 930 holes with 0.32mm has been reported (Benedict, 1973) using hypodermic needles.

- 16. Thank you

Editor's Notes

- #4: Ultrasonic machining, also known as ultrasonic impact grinding, is a machining operation in which a vibrating tool oscillating at ultrasonic frequencies is used to remove material from the workpiece, aided by an abrasive slurry that flows freely between the workpiece and the tool. It differs from most other machining operations because very little heat is produced. The tool never contacts the workpiece and as a result the grinding pressure is rarely more than 2 pounds,which makes this operation perfect for machining extremely hard and brittle materials, such as glass, sapphire, ruby, diamond, and ceramics.

- #6: In ultrasonic machining, tool of desired shape vibrates at ultrasonic frequency ( 19 to 25 kHz. ) with an amplitude of 15-50 Microns over work piece. Generally tool is pressed down with a feed force F. Between the tool and work, machining zone is flooded with hard abrasive particles generally in the form of water based slurry. As the tool vibrates over the work piece, abrasive particles acts as indenter and indent both work and tool material . Abrasive particles , as they indent , the work material would remove the material from both tool and work piece. In Ultrasonic machining material removal is due to crack initiation, propagation and brittle fracture of material. USM is used for machining hard and brittle materials, which are poor conductors of electricity and thus cannot be processed by Electrochemical machining ( ECM) or Electro discharge machining (EDM). The tool in USM is made to vibrate with high frequency on to the work surface in the midst of the flowing slurry. The main reason for using ultrasonic frequency is to provide better performance. Audible frequencies of required intensities would be heard as extremely loud sound and would cause fatigue and even permanent damage to the auditory apparatus.