Unit 1(part-1)Introduction of mechatronics

- 1. By V.D.TAMILARASAN Research associate cum Assistant Professor Mechanical Engineering Department Bannari Amman Institute of Technology INTRODUCTION OF MECHATRONICS 1 MECHATRONICS

- 2. Topics 2 SL.NO TOPIC 1 Introduction to Mechatronics systems, Concepts & Application. 2 Mechatronics System Components with examples 3 Measurement Systems, Control systems, Open & Closed Loop Systems. 4 Sequential Controllers with examples â Water level controller. 5 Shaft speed control, Washing machine control.

- 3. 3 ïThe word mechatronics was originated from Japan (Yasakawa Electric Company) in the late 1960s, spread through Europe, and is now commonly used round the globe. ïâThe word, mechatronics, is composed of âmechaâ from mechanism and the âtronicsâ from electronics. ïMechatronics solves technological problems using interdisciplinary knowledge consisting of mechanical engineering, electronics, and computer technology. ïIn 1996, Harashima, Tomizuka, and Fukuda defined mechatronics as being âthe synergistic integration of mechanical engineering, with electronics and intelligent computer control in the design and manufacturing of industrial products and processes.â ïBolton presented yet another definition by saying âa mechatronic system is not just a marriage of electrical and mechanical systems and is more than just a control system; the mechatronic system is a complete integration of them all.â ïMechatronics is the field of study concerned with the design, selection, analysis, and control of systems that combine mechanical elements with electronic components, including computers and/or microcontrollers. Introduction to Mechatronics Systems

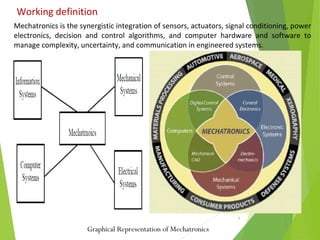

- 4. 4 Mechatronics is the synergistic integration of sensors, actuators, signal conditioning, power electronics, decision and control algorithms, and computer hardware and software to manage complexity, uncertainty, and communication in engineered systems. Working definition Graphical Representation of Mechatronics

- 5. 5

- 6. 6 Evolution of Mechatronics Technological advances in design, manufacturing, and operation of engineered products/devices/processes can be traced through: â Industrial revolution â Semiconductor revolution â Information revolution Industrial Revolution âą Allowed design of products and processes for energy conversion and transmission thus allowing the use of energy to do useful work. âą Engineering designs of this era were largely mechanical â e.g., operations of motion transmission, sensing, actuation, and computation were performed using mechanical components such as cams, gears, levers, and linkages). âą Purely mechanical systems suffer from â Power amplification inability. â Energy losses due to tolerances, inertia, and friction.

- 7. 7

- 8. 8 Semiconductor Revolution âą Led to the creation of integrated circuit (IC) technology. âą Effective, miniaturized, power electronics could amplify and deliver needed amount of power to actuators. âą Signal conditioning electronics could filter and encode sensory data in analog/digital format. âą Hard-wired, on-board, discrete analog/digital ICs provided rudimentary computational and decision-making circuits for control of mechanical devices.

- 9. 9 Information Revolution âą Development of VLSI technology led to the introduction of microprocessor, microcomputer, and microcontroller. âą Now computing hardware is everywhere, cheap, and small. âą As computing hardware can be effortlessly interfaced with real world electromechanical systems, it is now routinely embedded in engineered products/processes for decision- making. â Microcontrollers are replacing precision mechanical components, e.g., precision machined camshaft that in many applications functions as a timing device. â Programmability of microcontrollers is providing a versatile and flexible alternative to the hard-wired analog/digital computational hardware. â Integrated computer-electrical-mechanical devices are now capable of converting, transmitting, and processing both the physical energy and the virtual energy (information). âą Result: Highly efficient products and processes are now being developed by judicious selection and integration of sensors, actuators, signal conditioning, power electronics, decision and control algorithms, and computer hardware and software.

- 10. 10 Mechatronics has evolved through the following stages: âą Primary Level Mechatronics: Integrates electrical signaling with mechanical action at the basic control level for e.g.fluid valves and relay switches âą Secondary Level Mechatronics: Integrates microelectronics into electrically controlled devices for e.g. cassette tape player. âą Tertiary Level Mechantronics: Incorporates advanced control strategy using microelectronics, microprocessors and other application specific integrated circuits for e.g. microprocessor based electrical motor used for actuation purpose in robots. âą Quaternary Level Mechatronics: This level attempts to improve smartness a step ahead by introducing intelligence ( artificial neutral network and fuzzy logic ) and fault detection and isolation ( F.D.I.) capability into the system.

- 11. 11 Mechatronics Applications âą Smart consumer products: home security, camera, microwave oven, toaster, dish washer, laundry washer-dryer, climate control units, Automatic Digital Cemera etc. âąComputer disk VCR/DVD drives, ATM, etc âą Medical: implant-devices, assisted surgery, haptic, etc. âą Defense: unmanned air, ground, and underwater vehicles, smart weapons, jet engines, etc. âą Manufacturing: NC & CNC machine tools, Rapid Prototyping, robotics, etc. âą Automotive: climate control, antilock brake, active suspension, cruise control, air bags, engine management, safety, etc. âą Network-centric, distributed systems: distributed robotics, telerobotics, intelligent highways, etc.

- 12. 12

- 13. 13

- 14. 14

- 15. 15

- 16. 16

- 17. 17 Advantages of Mechatronics ïCost effective and good quality products ïHigh degree of flexibility to modify or redesign ïVery good performance characteristics ïWide are of application ïGreater productivity in case of manufacturing organization ïGreater extend of machine utilization Disadvantages of Mechatronics ïHigh Initial cost ïMulti-disciplinary engineering background required to design and implementation ïNeed of highly trained workers ïComplexity in identification an correction of problems in the system

- 18. 18 Elements of Mechatronics System Actuators & Sensors Signals & Conditioning Digital Logic System Software & Data acquisition Systems Computers & Display devices

- 19. 19

- 20. 20 Actuators & Sensors Sensors and actuators come under mechanical systems Actuators Sensors The actuators produce motion or cause some action The sensors detect the state of the system parameters, inputs and outputs Various actuators: Pneumatic an hydraulic actuators, Electro Mechanical actuators, Piezoelectric, Electrical Motors, i.e. D.C, A.C, Stepper, Servo motors. Various Sensors: Liner and rotaional sensors, acceleration sensors, force, torque, pressure sensor, temperature, proximity and light sensors.

- 21. 21

- 22. 22

- 23. 23

- 24. 24

- 25. 25 Signals & Conditioning ïMechatronic system deals with two types of signals and conditioning , i.e. Input & Output ïInput devices receive input signals from the mechatronics system via interfacing devices an sensors. ïFrom sensors the signal is send to the control circuits for conditioning or processing. ïVarious input signal conditioning devices are amplifiers, A2D, D2D converters . ïOutput signals from the system are send to the output/display devices through interfacing devices ïVarious output signal conditioning devices are D2A, display decoders, power transistors, op-amps.

- 26. 26 Digital Thermometer The thermocouple is a transducer that converts temperature to a small voltage; the amplifier increases the magnitude of the voltage; the A/D (analog-to-digital) converter is a device that changes the analog signal to a coded digital signal; and the LEDs (light emitting diodes) display the value of the temperature.

- 27. 27 Digital Logic System It will control overall system operation Various digital logic systems are logic circuits, microcontrollers, PLC, sequencing & timing controls

- 28. 28

- 29. 29 Software & Data acquisition Systems ïData acquisition system acquires the output signals from sensors in the form of voltage, frequency, resistance etc. an inputting into the microprocessor or computer. ïSoftware is used to control the acquisition of data through DAC board. ïData acquisition system consists of multiplexer, amplifier, register and control circuits. ïSoftware Examples: Ladder Logic, Visual C++, Visual Basic, Lab VIEW, MATLAB, Lab Chart, LOX

- 31. 31 Computers and display devices Computers are use to store large amount of data and process further through software. Display devices are used to give visual feedback to the user. Display devices are LED, CRT, LCD, Digital displays etc.

- 32. 32 Measurement System What is a system? MOTOR Input, Electrical Power Output, Rotaion Not concentrate on what goes on inside Concentrate only on output & Input device Measurement system? Measuring Input quantity Output the value of quantity Measurement System ThermometerInput Temp. Output number on scale

- 33. 33 Digital Thermometer The thermocouple is a transducer that converts temperature to a small voltage; the amplifier increases the magnitude of the voltage; the A/D (analog-to-digital) converter is a device that changes the analog signal to a coded digital signal; and the LEDs (light emitting diodes) display the value of the temperature.

- 34. 34 Control System To control the output to some particular value or particular sequence of values Central Heating system Input, required temperature Output, temperature at the set value

- 35. Difference between Open loop and Closed loop system SI.No. Open loop system Closed loop system 1 Not using feedback Feedback using 2 Less accurate More accurate 3 Simple in construction Complicated in construction 4 Optimisation in control is not possible Optimisation in control is possible 5 Easy maintenance & cost is less Difficult to maintain & cost is more 6 Eg. CD deck, Digital thermometer Eg. Automatic water level, washing machine

- 36. Open Loop system

- 38. Basic Elements of a closed loop system 1. Comparison element 2. Control element 3. Correction element 4. Process elements 5. Measurement elements

- 39. Various elements for controlling the room temperature. Controlled variable - the room temperature Reference value - the required room temperature Comparison element - the person comparing the measured value wit required temp. Error signal - difference between measured and required temperatures Control unit - the person Correction unit - the switch on the fire Process unit - the heating by the fire Measuring device - a thermometer

- 45. Automatic Camera