unit_2.pptx

- 1. UNIT II DIESEL, GAS TURBINE AND COMBINED CYCLE POWER PLANTS âĒ Otto, Diesel, Dual & Brayton Cycle â Analysis & Optimisation. Components of Diesel and Gas Turbine power plants. Combined Cycle Power Plants. Integrated Gasifier based Combined Cycle systems.

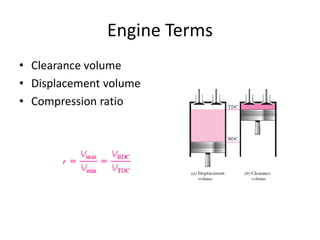

- 2. Engine Terms âĒ Clearance volume âĒ Displacement volume âĒ Compression ratio

- 3. Engine Terms âĒ Mean effective pressure (MEP)

- 4. Otto Cycle âĒ Processes of Otto Cycle: âĒ Isentropic compression âĒ Constant-volume heat addition âĒ Isentropic expansion âĒ Constant-volume heat rejection

- 5. OTTO CYCLE

- 6. Otto Cycle âĒ Ideal Otto Cycle âĒ Four internally reversible processes â 1-2 Isentropic compression â 2-3 Constant-volume heat addition â 3-4 Isentropic expansion â 4-1 Constant-volume heat rejection

- 7. Otto Cycle âĒ Closed system, pe, ke â 0 âĒ Energy balance (cold air std)

- 8. Otto Cycle âĒ Thermal efficiency of ideal Otto cycle: âĒ Since V2= V3 and V4 = V1 âĒ Where r is compression ratio k is ratio of specific heats

- 9. Otto Cycle

- 15. Spark and Compression Ignition âĒ Spark (Otto), air-fuel mixture compressed (constant-volume heat addition) âĒ Compression (Diesel), air compressed, then fuel added (constant-pressure heat addition)

- 16. DIESEL CYCLE

- 17. Diesel Cycle âĒ Processes of Diesel cycle: âĒ Isentropic compression âĒ Constant-pressure heat addition âĒ Isentropic expansion âĒ Constant-volume heat rejection

- 18. Diesel Cycle âĒ For ideal diesel cycle âĒ With cold air assumptions

- 19. Diesel Cycle âĒ Cut off ratio rc âĒ Efficiency becomes

- 25. Process 1 ï 2 Isentropic compression Process 2 ï 2.5 Constant volume heat addition Process 2.5 ï 3 Constant pressure heat addition Process 3 ï 4 Isentropic expansion Process 4 ï 1 Constant volume heat rejection Dual Cycle Qin Qin Qout 1 1 2 2 2.5 2.5 3 3 4 4 ) ( ) ( ) ( ) ( 5 . 2 3 2 5 . 2 5 . 2 3 2 5 . 2 T T c T T c h h u u m Q p v in ï ïŦ ï ï― ï ïŦ ï ï―

- 26. Thermal Efficiency ) ( ) ( 1 1 5 . 2 3 2 5 . 2 1 4 h h u u u u m Q m Q in out cycle Dual ï ïŦ ï ï ï ï― ï ï― ïĻ ïĻ ïĐïš ïŧ ïđ ïŠ ïŦ ïĐ ï ïŦ ï ï ï ï― ï 1 ) 1 ( 1 1 1 1 c k c k c const Dual r k r r v ïĄ ïĄ ïĄ ïĻ 1 1 1 ï ï ï― k Otto r ïĻ ïĻ ïĐ ïĻ ïĐïš ïŧ ïđ ïŠ ïŦ ïĐ ï ï ï ï ï― ï 1 1 1 1 1 1 c k c k const c Diesel r r k r V ïĻ Note, the Otto cycle (rc=1) and the Diesel cycle (ïĄ=1) are special cases: 2 3 5 . 2 3 and where P P v v rc ï― ï― ïĄ

- 27. The use of the Dual cycle requires information about either: i) the fractions of constant volume and constant pressure heat addition (common assumption is to equally split the heat addition), or ii) maximum pressure P3. Transformation of rc and ïĄ into more natural variables yields ïš ïŧ ïđ ïŠ ïŦ ïĐ ï ï ï ï· ï· ïļ ïķ ï§ ï§ ïĻ ïĶ ï ï ï― ï 1 1 1 1 1 1 1 1 k r V P Q k k r k in c ïĄ ïĄ 1 3 1 P P rk ï― ïĄ For the same initial conditions P1, V1 and the same compression ratio: Diesel Dual Otto ïĻ ïĻ ïĻ ïū ïū For the same initial conditions P1, V1 and the same peak pressure P3 (actual design limitation in engines): otto Dual Diesel ïĻ ïĻ ïĻ ïū ïū

- 29. Brayton Cycle âĒ Gas turbine cycle âĒ Open vs closed system model

- 30. Brayton Cycle âĒ Four internally reversible processes â 1-2 Isentropic Compression (compressor) â 2-3 Constant-pressure heat addition â 3-4 Isentropic expansion (turbine) â 4-1 Constant-pressure heat rejection

- 31. Brayton Cycle âĒ Analyze as steady-flow process âĒ So âĒ With cold-air-standard assumptions

- 32. Brayton Cycle âĒ Since processes 1-2 and 3-4 are isentropic, P2 = P3 and P4 = P1 where

- 33. Brayton Cycle

- 34. Brayton Cycle âĒ Back work ratio âĒ Improvements in gas turbines â Combustion temp â Machinery component efficiencies â Adding modifications to basic cycle

- 39. Actual Gas-Turbine Cycles âĒ For actual gas turbines, compressor and turbine are not isentropic