Urea production process

- 2. Where I did training ? National fertilizers limited (N.F.L) A public sector undertaking Vijaipur, Guna (M.P)

- 3. Introduction about NFL •NFL is one of the largest contributor of nitrogenous fertilizer in the country. It was started on 23 august 1974. • It is the first company to be permitted by Govt. of india to produce and market neem coated urea. •Four units – line 1 ammonia line 2 ammonia line 1 urea line 2 urea • CPP and waste heat reboiler •DM water plant supplies water to Boiler feed water (BFW)

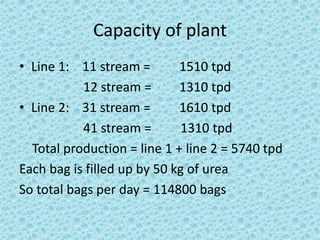

- 4. Capacity of plant • Line 1: 11 stream = 1510 tpd 12 stream = 1310 tpd • Line 2: 31 stream = 1610 tpd 41 stream = 1310 tpd Total production = line 1 + line 2 = 5740 tpd Each bag is filled up by 50 kg of urea So total bags per day = 114800 bags

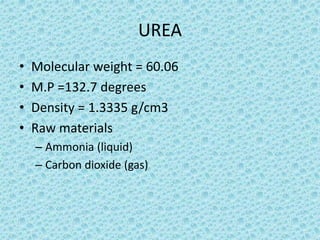

- 5. UREA • Molecular weight = 60.06 • M.P =132.7 degrees • Density = 1.3335 g/cm3 • Raw materials – Ammonia (liquid) – Carbon dioxide (gas)

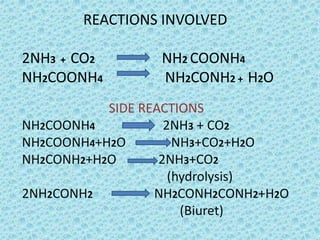

- 6. REACTIONS INVOLVED 2NH3 + CO2 NH2 COONH4 NH2COONH4 NH2CONH2 + H2O SIDE REACTIONS NH2COONH4 2NH3 + CO2 NH2COONH4+H2O NH3+CO2+H2O NH2CONH2+H2O 2NH3+CO2 (hydrolysis) 2NH2CONH2 NH2CONH2CONH2+H2O (Biuret)

- 7. PARAMETERS AFFECTING PROCESS 1. Temperature : • Maximum equilibrium conversion around 190-200⁰C. •Higher temperature leads to corrosion 2. Pressure: • equilibrium pressure becomes higher when temperature increases 3.Residence Time: •minimum R.T. to attain equilibrium = 20 min.

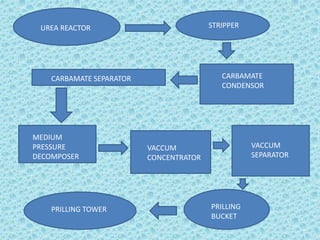

- 8. UREA REACTOR STRIPPER CARBAMATE SEPARATOR CARBAMATE CONDENSOR MEDIUM PRESSURE DECOMPOSER VACCUM CONCENTRATOR VACCUM SEPARATOR PRILLING TOWER PRILLING BUCKET

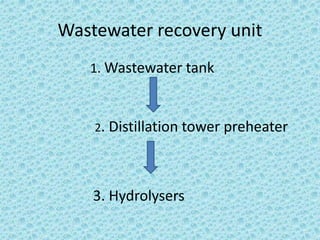

- 10. Wastewater recovery unit 1. Wastewater tank 2. Distillation tower preheater 3. Hydrolysers

- 11. Categories of urea 1. Agricultural based urea 2. Technical based urea 3. coated urea

- 12. Specifications for Prilling tower Airflow through Prilling tower is 12000 Nm3/ton PRILL SIZE PRILLING TOWER 1. 2mm 2. 3mm 3. 4mm 90 meters 150 meters 220 meters

- 13. CONCLUSIONS 1. Policies: Environment policy(ISO-14001) Quality policy (ISO-9001) Energy policy Health and safety policy(ISO-9001) 2. Products: Kisan urea HNO3,NH4NO3,NaNO3,S,Menthol,N2 etc 3. Bio fertilizer plant: Psb, Rhizobium,Azotobacter