Value Stream Mapping

- 1. Value Stream Mapping SUMMARY OF LEARNINGS IN CLASS BY ~ANAND PANDEY ~by Mohit Budhiraja

- 2. Agenda â Introduction â Benefits of Value Stream Mapping â The 8 waste of lean â Calculating Efficiency at different workflow stage â Value Stream Mapping Process â Current State Mapping â Future State Mapping â Gap Analysis â Implementing Value Stream Mapping 2

- 3. Introduction: Value Stream Mapping, Definition, Purpose â Value Stream Mapping: Value Stream Mapping is a lean management tool used to visualize and analyze the steps and activities involved in delivering a product or service to a customer, with the aim of identifying and eliminating waste, improving efficiency, and increasing customer value. â Definition: Value Stream Mapping is a visual representation of the flow of materials and information through the process, from the initial order to delivery, with a focus on identifying value- adding and non-value-adding activities. â Purpose: The purpose of Value Stream Mapping is to provide a holistic view of the entire process, enabling stakeholders to understand the current state, envision the future state, and identify opportunities for improvement. 3

- 4. 4 Benefits of Value Stream Mapping: Identifying Waste, Improving Efficiency, Increasing Customer Value â Identifying Waste: Value Stream Mapping helps to uncover and eliminate various forms of waste, including overproduction, waiting times, unnecessary movement, and defects, leading to cost reduction and improved resource utilization. â Improving Efficiency: By visualizing the production process, Value Stream Mapping allows organizations to identify and streamline inefficient activities, reduce lead times, and optimize resource allocation, resulting in improved overall operational efficiency. â Increasing Customer Value: Value Stream Mapping enables organizations to focus on value-adding activities and prioritize customer satisfaction, leading to the delivery of higher quality products or services with a reduced time-to-market, enhancing customer value and brand reputation. 4

- 5. 5 The 8 Waste of Lean 5

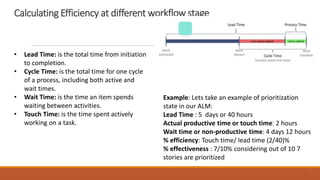

- 6. 6 Calculating Efficiency at different workflow stage 6 âĒ Lead Time: is the total time from initiation to completion. âĒ Cycle Time: is the total time for one cycle of a process, including both active and wait times. âĒ Wait Time: is the time an item spends waiting between activities. âĒ Touch Time: is the time spent actively working on a task. Example: Lets take an example of prioritization state in our ALM: Lead Time : 5 days or 40 hours Actual productive time or touch time: 2 hours Wait time or non-productive time: 4 days 12 hours % efficiency: Touch time/ lead time (2/40)% % effectiveness : 7/10% considering out of 10 7 stories are prioritized

- 7. 7 Value Stream Mapping Process â Current State Mapping: Analyzing the existing processes and identifying value-adding and non- value-adding activities â Future State Mapping: Envisioning the ideal process flow and identifying improvement opportunities â Gap Analysis: Identifying gaps between the current and future state, prioritizing improvement areas Current State Mapping, Future State Mapping, Gap Analysis 7

- 8. 8 Current State Mapping â Data Collection: Gathering relevant information about the current processes and their performance metrics â Process Analysis: Thoroughly examining the current workflow, time, and resource utilization â Value-adding and Non-value- adding Activities: Distinguishing activities that directly contribute to value creation from those that do not Data Collection, Process Analysis, Value-adding and Non-value-adding Activities 8

- 9. 9 Future State Mapping â Identifying Improvement Opportunities: Spotting areas for enhancement and streamlining in the workflow and processes â Developing Ideal Process Flow: Creating a visual representation of the desired optimized process and identifying key improvements Identifying Improvement Opportunities, Developing Ideal Process Flow 9

- 10. Gap Analysis â Identifying gaps between current and future state: Contrasting the existing processes with the envisioned future state to highlight discrepancies and areas needing improvement â Prioritizing Improvement Areas: Ranking areas of improvement based on their impact on value, efficiency, and customer satisfaction 10 Identifying gaps between current and future state, Prioritizing Improvement Areas

- 11. 11 Implementing Value Stream Mapping â Engaging Stakeholders: Involving and collaborating with relevant stakeholders to gather insights and align on improvement goals â Developing Value Stream Transformation Plan: Creating a detailed plan that outlines specific actions, responsibilities, and timelines for implementing improvements â Continuous Improvement: Establishing a culture of ongoing improvement and adaptation to enhance value stream processes over time Engaging Stakeholders, Developing Action Plan, Continuous Improvement 11

- 12. 12