Valve

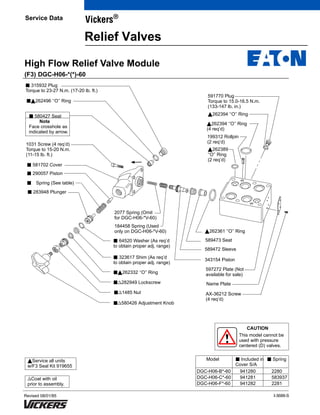

- 1. Revised 08/01/85 I-3688-S High Flow Relief Valve Module (F3) DGC-H06-*(*)-60 Service Data J 315932 Plug Torque to 23-27 N.m. (17-20 lb. ft.) JY262496 ‘‘O’’ Ring J 580427 Seat Note Face crosshole as indicated by arrow. 1031 Screw (4 req’d) Torque to 15-20 N.m. (11-15 lb. ft.) J 581702 Cover J 290057 Piston J Spring (See table) J 283948 Plunger JY262332 ‘‘O’’ Ring Jn282949 Lockscrew Jn1485 Nut Jn580426 Adjustment Knob J 323617 Shim (As req’d to obtain proper adj. range) J 64520 Washer (As req’d to obtain proper adj. range) Y262361 ‘‘O’’ Ring 589473 Seat 343154 Piston 184458 Spring (Used only on DGC-H06-*V-60) 2077 Spring (Omit for DGC-H06-*V-60) Y262389 ‘‘O’’ Ring (2 req’d) 199312 Rollpin (2 req’d) Y262394 ‘‘O’’ Ring (4 req’d) Y262394 ‘‘O’’ Ring 591770 Plug Torque to 15.0-16.5 N.m. (133-147 lb. in.) CAUTION This model cannot be used with pressure centered (D) valves. YService all units w/F3 Seal Kit 919655 nCoat with oil prior to assembly. Model J Included in Cover S/A J Spring DGC-H06-B*-60 DGC-H06-C*-60 DGC-H06-F*-60 941280 941281 941282 2280 583937 2281 597272 Plate (Not available for sale) Name Plate AX-36212 Screw (4 req’d) 589472 Sleeve Vickers? Relief Valves

- 2. – 2 – 3 4 5 61 2 Model Code 1 2 Seals F3 - Seals for mineral oil and fire resistant fluids Model Series DGC - Directional control, subplate mounted relief module High Flow H - 70 USgpm 3 4 5 6Size 06 - 3/4 inch Pressure Range B - 125-1000 psi C - 500-2000 psi F - 1500-3000 psi Vent Spring V - High vent spring (Omit for low vent models) Design For satisfactory service life of these components, use full flow filtration to provide fluid which meets ISO cleanliness code 18/15 or cleaner. Selections from Eaton OFP,OFR and OFRS filter series are recommended. Printed in U.S.A. 7 7