Vapor Phase Deposition Techniques

- 2. Introduction  Vapor Phase Deposition (VPD) technique is a method of preparing the extremely pure optical glasses.  Vapor Phase methods are the ones that are now used to produce silica-based fibers with very low attenuation, highest transparency with the optimal optical properties. 2

- 3. Ingredients Starting Materials Dopants Starting materials are volatile organic compounds such as: o SiCl4 o GeCl4 o SiF4 o BCL3 o O2 o BBr3 o POCl3 Refractive index modification is achieved through the formation of dopants from the non-silica starting materials: o TiO2 o GeO2 o P2O5 o Al2O3 o B2O3 o F 3

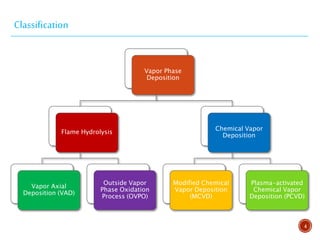

- 4. Classification 4 Vapor Phase Deposition Flame Hydrolysis Vapor Axial Deposition (VAD) Outside Vapor Phase Oxidation Process (OVPO) Chemical Vapor Deposition Modified Chemical Vapor Deposition (MCVD) Plasma-activated Chemical Vapor Deposition (PCVD)

- 6. Outside Vapor Phase Oxidation (OVPO) o Uses flame hydrolysis stems from work on soot processes which were used to produce the first fiber with losses of less than 20 dBKm-1. o Oxygen is passed through the silicon compound which is vaporized removing impurities. o Dopants are added and gave following reactions: 6

- 7. Outside Vapor Phase Oxidation (OVPO) (cont.) o The silica is regenerated as a fine soot which is deposited on a cool rotating mandrel. The flame is reversed back and forth over the length of the mandrel for getting sufficient numbers of silica layers. o After the process ends, the mandrel is removed and the porous mass of silica soot is sintered. 7

- 8. Vapor Axial Depositions (VAD) o Continuous technique for producing low loss optical fibers. o Vaporized constituents are injected from burners and react to form silica soot by flame hydrolysis and makes a solid porous glass preform. o The preform is pulled upwards. o Dehydrated by heating with SOCl2 using the reaction: Fig: The VAD Process 8

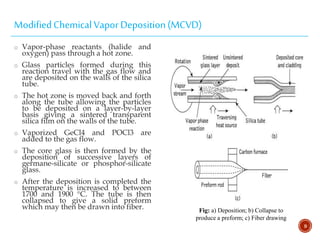

- 9. Modified Chemical Vapor Deposition (MCVD) o Vapor-phase reactants (halide and oxygen) pass through a hot zone. o Glass particles formed during this reaction travel with the gas flow and are deposited on the walls of the silica tube. o The hot zone is moved back and forth along the tube allowing the particles to be deposited on a layer-by-layer basis giving a sintered transparent silica film on the walls of the tube. o Vaporized GeCl4 and POCl3 are added to the gas flow. o The core glass is then formed by the deposition of successive layers of germane-silicate or phosphor-silicate glass. o After the deposition is completed the temperature is increased to between 1700 and 1900 °C. The tube is then collapsed to give a solid preform which may then be drawn into fiber. 9 Fig: a) Deposition; b) Collapse to produce a preform; c) Fiber drawing

- 10. The MCVD Process 10

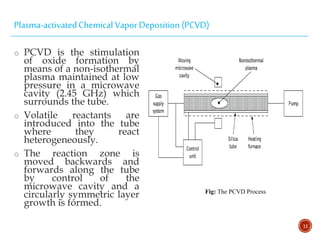

- 11. Plasma-activated Chemical Vapor Deposition (PCVD) o PCVD is the stimulation of oxide formation by means of a non-isothermal plasma maintained at low pressure in a microwave cavity (2.45 GHz) which surrounds the tube. o Volatile reactants are introduced into the tube where they react heterogeneously. o The reaction zone is moved backwards and forwards along the tube by control of the microwave cavity and a circularly symmetric layer growth is formed. 11 Fig: The PCVD Process

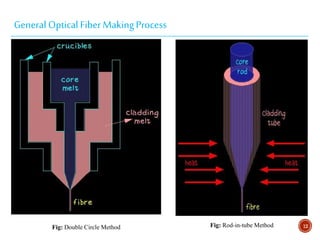

- 12. General Optical Fiber Making Process Fig: Double Circle Method Fig: Rod-in-tube Method 12

- 13. General Optical Fiber Making Process 13

- 14. Summery o Both step index and graded index fibers are made with these processes. o Gives relatively similar performance for the fabrication of both multi-mode and single-mode fibers. o MCVD and VAD technique employed together as MCVD-VAD hybrid technique for producing polarization maintaining fiber. 14