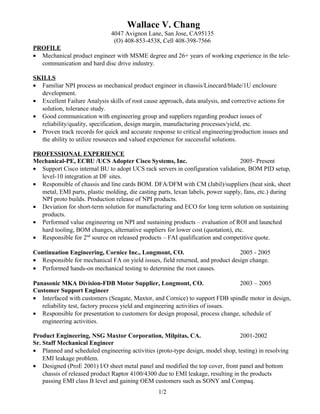

Wallace Chang Resume

- 1. Wallace V. Chang 4047 Avignon Lane, San Jose, CA95135 (O) 408-853-4538, Cell 408-398-7566 PROFILE • Mechanical product engineer with MSME degree and 26+ years of working experience in the tele- communication and hard disc drive industry. SKILLS • Familiar NPI process as mechanical product engineer in chassis/Linecard/blade/1U enclosure development. • Excellent Failure Analysis skills of root cause approach, data analysis, and corrective actions for solution, tolerance study. • Good communication with engineering group and suppliers regarding product issues of reliability/quality, specification, design margin, manufacturing processes/yield, etc. • Proven track records for quick and accurate response to critical engineering/production issues and the ability to utilize resources and valued experience for successful solutions. PROFESSIONAL EXPERIENCE Mechanical-PE, ECBU /UCS Adopter Cisco Systems, Inc. 2005- Present • Support Cisco internal BU to adopt UCS rack servers in configuration validation, BOM PID setup, level-10 integration at DF sites. • Responsible of chassis and line cards BOM. DFA/DFM with CM (Jabil)/suppliers (heat sink, sheet metal, EMI parts, plastic molding, die casting parts, lexan labels, power supply, fans, etc.) during NPI proto builds. Production release of NPI products. • Deviation for short-term solution for manufacturing and ECO for long term solution on sustaining products. • Performed value engineering on NPI and sustaining products – evaluation of ROI and launched hard tooling, BOM changes, alternative suppliers for lower cost (quotation), etc. • Responsible for 2nd source on released products – FAI qualification and competitive quote. Continuation Engineering, Cornice Inc., Longmont, CO. 2005 - 2005 • Responsible for mechanical FA on yield issues, field returned, and product design change. • Performed hands-on mechanical testing to determine the root causes. Panasonic MKA Division-FDB Motor Supplier, Longmont, CO. 2003 – 2005 Customer Support Engineer • Interfaced with customers (Seagate, Maxtor, and Cornice) to support FDB spindle motor in design, reliability test, factory process yield and engineering activities of issues. • Responsible for presentation to customers for design proposal, process change, schedule of engineering activities. Product Engineering, NSG Maxtor Corporation, Milpitas, CA. 2001-2002 Sr. Staff Mechanical Engineer • Planned and scheduled engineering activities (proto-type design, model shop, testing) in resolving EMI leakage problem. • Designed (ProE 2001) I/O sheet metal panel and modified the top cover, front panel and bottom chassis of released product Raptor 4100/4300 due to EMI leakage, resulting in the products passing EMI class B level and gaining OEM customers such as SONY and Compaq. 1/2

- 2. Product Engineering, Quantum (Maxtor) Corporation, Milpitas, CA. 1993-2001 Senior Mechanical Product Engineer • Tolerance study and created DOE (Design of Experiment) to test out the product margin. Performed testing jobs and failure analysis of mechanical issues for DOE. • Responsible for F/A report and corrective actions for solution. • Worked proactively with reliability/quality group on mechanical engineering problems in DVT and DMT, such as acoustic test, shock/vibration failures, altitude test, thermal test, package drop test, over stress test, etc during product development. • Responsible for all mechanical issues of customer’s complaints of the released products – analyzed the data, identified the root causes and worked closely with manufacturer MKE about the feasible solutions, implemented corrective actions in quick response to satisfy customer’s requirements, enabling production and shipping in schedules. Major completion included actuator arm thickness change due to head slap fragility, screen process for excessive vibration drive due to imbalance spindle motor, PCB protected shield design; connector clips strengthen design, etc. • Worked closely with manufacturer MKE and motor vendors on critical mechanical issues such as arm resonance due to asymmetry, noise motor due to defect, flex cable fatigue, marginal component/assembly (tolerance study), etc. to improve the production yield. • Worked closely with supplier quality group, reliability/quality groups in supplier quality issues. Design/Continuation Engineering, Seagate Technology, Scotts Valley, CA. 1990-1993 Mechanical Design Engineer • Worked with vendor for spindle motor design – torque constant Kt, loop resistance, starting torque, flux leakage, rocking mode resonance, RRO/NRRO, acoustics, etc. • Performed failure analysis of component’s and drive’s level – suspension 1st bending and torsion mode, crash stop bang-bang compression test, drop test for head slap fragility, seeking and idle acoustics, magnetic latch stiction, head stiction vs. motor starting torque, PES runout spectra analysis, shock/vibration test, particle count, tolerance study, disk clamping force vs. screw torque, etc. • Worked closely with reliability/quality group for drive’s failure analysis. Kaitek Inc. San Jose, CA. 1988-1990 QA Engineer • Collected and reviewed statistic process control data of production line, fully support to do F/A for yield issues. • Arranged and assigned jobs to operators and key leaders for production issues. • Testing – stiction torque, start/stop, lubricant thickness (ESCA, FTIR) etc. EDUCATION Master of Science in Mechanical Engineering, San Jose State University, CA. 1986-1987 Bachelor of Science in Mechanical Engineering, Chung-Yung University, Taiwan. 1978-1982 Fluent in Mandarin and English. US citizen. 2/2