WATER Mgmt PPT for NSI 29.04.16

- 2. AREAS OF EXPERTISE WATER RECOVERY ZERO LIQUID DISCHARGE ONLINE MONITORING SEA WATER DESALINATION

- 3. We are a company in the field of WATER RECOVERY. Absolute Water Pvt Ltd., is an integrated cleantech company that provides turnkey solutions for converting waste into most critical resource CLEAN WATER. Leveraging its 30+ experience in technology development and deployment, Absolute Water specializes in Concept, Design, Erect & Commission of complete water recovery systems. Absolute Water can treat any kind of water irrespective of its source or contamination level and produce clean water, including 100% drinkable water. WHO WE ARE

- 4. T I T L E

- 5. MINISTRY OF ENVIRONMENT, FORESTS AND CLIMATE CHANGE NOTIFICATION, NEW DELHI, 14TH JANUARY, 2016. IN THE GAZETTE OF INDIA S.NO INDUSTRY PARAMETERS STANDARDS (1) (2) (3) (4) 4. SUGAR INDUSTRY EFFUENTS All concentration values are in milligramme per litre except for pH pH 5.5 -8.5 Total Suspended Solids (TSS) 100 (for disposal on land) 30 (for disposal surface waters) Biological Oxygen Demand BOD [3 days at 270C] 100 (for disposal on land) 30 (for disposal on surface waters) Oil & Grease 10 Total Dissolved Solids (TDS) 2100 Final wastewater discharge limit 200 litre per tonne of cane crushed (Final treated effluent discharge restricted to 100 litre per tonne of cane crushed and waste water from spray pond overflow or cooling tower blow down to be restricted to 100 litre per tonne of cane crushed and only single outlet point from unit is allowed.) TABLE : 1

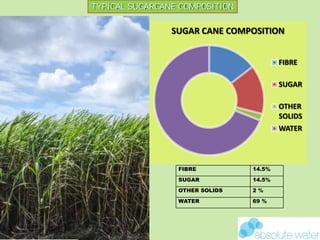

- 6. TYPICAL SUGARCANE COMPOSITION SUGAR CANE COMPOSITION FIBRE SUGAR OTHER SOLIDS WATER FIBRE 14.5% SUGAR 14.5% OTHER SOLIDS 2 % WATER 69 %

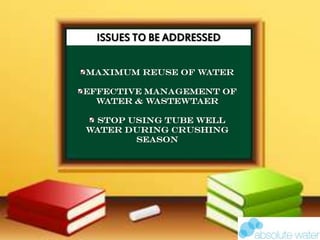

- 7. ISSUES TO BE ADDRESSED MAXIMUM REUSE OF WATER EFFECTIVE MANAGEMENT OF WATER & WASTEWTAER STOP USING TUBE WELL WATER DURING CRUSHING SEASON

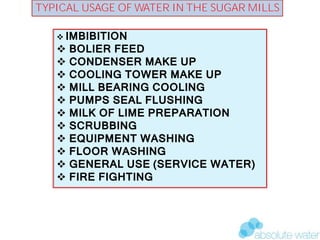

- 8. BIOGAS & POWER GENERATION POTENTIAL FROM DISTILLERY EFFLUENT TYPICAL USAGE OF WATER IN THE SUGAR MILLS ’üČ IMBIBITION ’üČ BOLIER FEED ’üČ CONDENSER MAKE UP ’üČ COOLING TOWER MAKE UP ’üČ MILL BEARING COOLING ’üČ PUMPS SEAL FLUSHING ’üČ MILK OF LIME PREPARATION ’üČ SCRUBBING ’üČ EQUIPMENT WASHING ’üČ FLOOR WASHING ’üČ GENERAL USE (SERVICE WATER) ’üČ FIRE FIGHTING

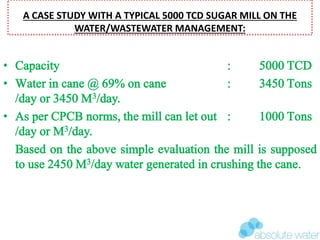

- 9. A CASE STUDY WITH A TYPICAL 5000 TCD SUGAR MILL ON THE WATER/WASTEWATER MANAGEMENT: ŌĆó Capacity : 5000 TCD ŌĆó Water in cane @ 69% on cane : 3450 Tons /day or 3450 M3/day. ŌĆó As per CPCB norms, the mill can let out : 1000 Tons /day or M3/day. Based on the above simple evaluation the mill is supposed to use 2450 M3/day water generated in crushing the cane.

- 10. WATER LOSSES IN THE SUGAR MANUFACTURING PROCESS WATER LOSS ESTIMATION: BASIS: 5000 TON OF CANE CRUSHED WITH THE FOLLOWING COMPOSITION: FIBRE : 14.5 %, SUGAR : 14.5 %, OTHER SOLIDS : 2 %, WATER : 69 % 1. BAGASSE : % Cane = 30 % Bagasse quantity = 300 T Bagasse moisture = 50 % Water in Bagasse = 750 T 2. FILTER CAKE: % Cake = 4 % Cake quantity = 200 T Cake moisture = 75% Water in filter cake = 150 T 3. MOLASSES : % Cane = 4 % Molasses quantity = 200 T Molasses moisture = 10 % Water in Molasses = 20 T 4. EVAPORATION LOSSES: Through vents, spray pond drift losses, condensate cooling, ash quenching, etc. Loss Through Vents : Assumed as 1 % of steam consumption. % Cane of steam consumption = 50 Steam Consumption = 2500 T Loss Through Vents = 25 T

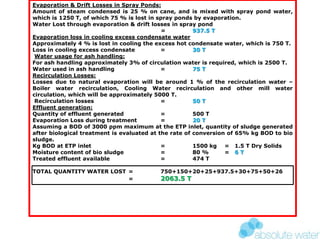

- 11. Evaporation & Drift Losses in Spray Ponds: Amount of steam condensed is 25 % on cane, and is mixed with spray pond water, which is 1250 T, of which 75 % is lost in spray ponds by evaporation. Water Lost through evaporation & drift losses in spray pond = 937.5 T Evaporation loss in cooling excess condensate water Approximately 4 % is lost in cooling the excess hot condensate water, which is 750 T. Loss in cooling excess condensate = 30 T Water usage for ash handling: For ash handling approximately 3% of circulation water is required, which is 2500 T. Water used in ash handling = 75 T Recirculation Losses: Losses due to natural evaporation will be around 1 % of the recirculation water ŌĆō Boiler water recirculation, Cooling Water recirculation and other mill water circulation, which will be approximately 5000 T. Recirculation losses = 50 T Effluent generation: Quantity of effluent generated = 500 T Evaporation Loss during treatment = 20 T Assuming a BOD of 3000 ppm maximum at the ETP inlet, quantity of sludge generated after biological treatment is evaluated at the rate of conversion of 65% kg BOD to bio sludge. Kg BOD at ETP inlet = 1500 kg = 1.5 T Dry Solids Moisture content of bio sludge = 80 % = 6 T Treated effluent available = 474 T TOTAL QUANTITY WATER LOST = 750+150+20+25+937.5+30+75+50+26 = 2063.5 T

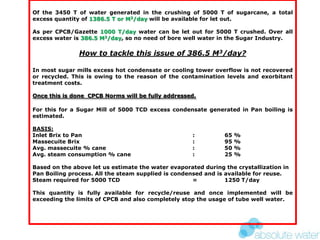

- 12. Of the 3450 T of water generated in the crushing of 5000 T of sugarcane, a total excess quantity of 1386.5 T or M3/day will be available for let out. As per CPCB/Gazette 1000 T/day water can be let out for 5000 T crushed. Over all excess water is 386.5 M3/day, so no need of bore well water in the Sugar Industry. How to tackle this issue of 386.5 M3/day? In most sugar mills excess hot condensate or cooling tower overflow is not recovered or recycled. This is owing to the reason of the contamination levels and exorbitant treatment costs. Once this is done CPCB Norms will be fully addressed. For this for a Sugar Mill of 5000 TCD excess condensate generated in Pan boiling is estimated. BASIS: Inlet Brix to Pan : 65 % Massecuite Brix : 95 % Avg. massecuite % cane : 50 % Avg. steam consumption % cane : 25 % Based on the above let us estimate the water evaporated during the crystallization in Pan Boiling process. All the steam supplied is condensed and is available for reuse. Steam required for 5000 TCD = 1250 T/day This quantity is fully available for recycle/reuse and once implemented will be exceeding the limits of CPCB and also completely stop the usage of tube well water.

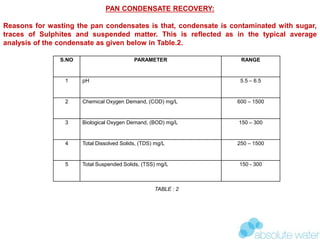

- 13. S.NO PARAMETER RANGE 1 pH 5.5 ŌĆō 6.5 2 Chemical Oxygen Demand, (COD) mg/L 600 ŌĆō 1500 3 Biological Oxygen Demand, (BOD) mg/L 150 ŌĆō 300 4 Total Dissolved Solids, (TDS) mg/L 250 ŌĆō 1500 5 Total Suspended Solids, (TSS) mg/L 150 - 300 PAN CONDENSATE RECOVERY: Reasons for wasting the pan condensates is that, condensate is contaminated with sugar, traces of Sulphites and suspended matter. This is reflected as in the typical average analysis of the condensate as given below in Table.2. TABLE : 2

- 14. CONTAMINANTS: ’ü▒ ACIDS (pH IS AROUND 5 ŌĆō 6.5) ’ü▒ COD/BOD ŌĆō DUE TO SUGAR ENTRAINMENT ’ü▒ TSS ŌĆō DUE TO AIRBORNE DUST & BACTERIAL ACTIVITY ’ü▒ HARDNESS ŌĆō DUE TO USAGE OF LIME SOLUTION FOR NEUTRALIZING IMPLICATIONS: ’ü▒ ALGAL BLOOMS IN THE COOLING TOWER & CIRCULATION LOOP ’ü▒ SCALING IN THE LINES CIRCULATION LINES ’ü▒ FREQUENT CHOKING OF SPRAY NOZZLES IN CONDENSER INJECTION AVAILABLE TREATMENT OPTIONS & DRAWBACKS: ’ü▒ COAGULATION/FILTRATION ŌĆō LARGE AMOUNT OF CHEMICAL SLUDGE GENERATION LEADING TO DISPOSAL PROBLEMS ’ü▒MBBR SYSTEM ŌĆō HUGE POWER REQUIREMENT (50 KW/hr for 1000 M3/day & ADDITIONAL SLUDGE GENERATION. ’ü▒ MEMBRANE SYSTEM ŌĆō ELABORATE PRETREATMENT REQUIRED, FOLLOWED BY HUGE CAPITAL INVESTMENT AND HUGE OPERATING COSTS.

- 15. TYPICAL APPEARNCE OF PAN CONDENSERS DRAIN / INJECTION WATER LOOP

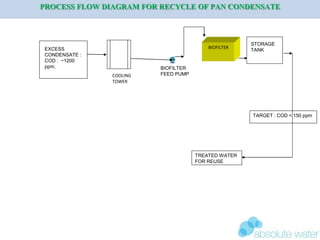

- 16. PROCESS FLOW DIAGRAM FOR RECYCLE OF PAN CONDENSATE EXCESS CONDENSATE : COD : ~1200 ppm, COOLING TOWER STORAGE TANK BIOFILTER BIOFILTER FEED PUMP TREATED WATER FOR REUSE TARGET : COD < 150 ppm

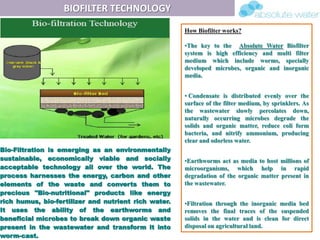

- 17. BIOFILTER TECHNOLOGY Bio-Filtration is emerging as an environmentally sustainable, economically viable and socially acceptable technology all over the world. The process harnesses the energy, carbon and other elements of the waste and converts them to precious "Bio-nutritional" products like energy rich humus, bio-fertilizer and nutrient rich water. It uses the ability of the earthworms and beneficial microbes to break down organic waste present in the wastewater and transform it into worm-cast. How Biofilter works? ŌĆóThe key to the Absolute Water Biofilter system is high efficiency and multi filter medium which include worms, specially developed microbes, organic and inorganic media. ŌĆó Condensate is distributed evenly over the surface of the filter medium, by sprinklers. As the wastewater slowly percolates down, naturally occurring microbes degrade the solids and organic matter, reduce coli form bacteria, and nitrify ammonium, producing clear and odorless water. ŌĆóEarthworms act as media to host millions of microorganisms, which help in rapid degradation of the organic matter present in the wastewater. ŌĆóFiltration through the inorganic media bed removes the final traces of the suspended solids in the water and is clean for direct disposal on agricultural land.

- 19. BIOFILTER TRIAL FOR PAN CONDENSATE IN A SUGAR MILL

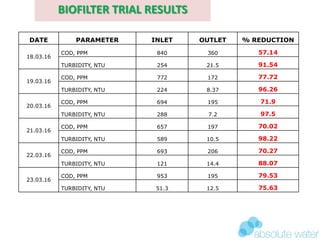

- 20. DATE PARAMETER INLET OUTLET % REDUCTION 18.03.16 COD, PPM 840 360 57.14 TURBIDITY, NTU 254 21.5 91.54 19.03.16 COD, PPM 772 172 77.72 TURBIDITY, NTU 224 8.37 96.26 20.03.16 COD, PPM 694 195 71.9 TURBIDITY, NTU 288 7.2 97.5 21.03.16 COD, PPM 657 197 70.02 TURBIDITY, NTU 589 10.5 98.22 22.03.16 COD, PPM 693 206 70.27 TURBIDITY, NTU 121 14.4 88.07 23.03.16 COD, PPM 953 195 79.53 TURBIDITY, NTU 51.3 12.5 75.63 BIOFILTER TRIAL RESULTS

- 21. TYPICAL USAGE OF RECOVERED WATER ’üČ IMBIBITION ’üČ BOLIER FEED ’üČ CONDENSER MAKE UP ’üČ COOLING TOWER MAKE UP ’üČ MILL BEARING COOLING ’üČ MILK OF LIME PREPARATION ’üČ DRINKING WATER PLANT FEED

![MINISTRY OF ENVIRONMENT, FORESTS AND CLIMATE CHANGE

NOTIFICATION, NEW DELHI, 14TH JANUARY, 2016.

IN THE GAZETTE OF INDIA

S.NO INDUSTRY PARAMETERS STANDARDS

(1) (2) (3) (4)

4. SUGAR INDUSTRY EFFUENTS All concentration values are in milligramme

per litre except for pH

pH 5.5 -8.5

Total Suspended Solids (TSS) 100 (for disposal on land)

30 (for disposal surface waters)

Biological Oxygen Demand BOD

[3 days at 270C]

100 (for disposal on land)

30 (for disposal on surface waters)

Oil & Grease 10

Total Dissolved Solids (TDS) 2100

Final wastewater discharge limit 200 litre per tonne of cane crushed

(Final treated effluent discharge restricted to 100 litre per tonne of cane crushed and

waste water from spray pond overflow or cooling tower blow down to be restricted to

100 litre per tonne of cane crushed and only single outlet point from unit is allowed.)

TABLE : 1](https://image.slidesharecdn.com/b3efebe7-38d3-4c67-b769-eaf43f3ec718-170209080443/85/WATER-Mgmt-PPT-for-NSI-29-04-16-5-320.jpg)