Welcometothepresentationon 131127120041-phpapp01

- 1. WELCOME TO THE PRESENTATION ON ŌĆ£ONE WAY SLAB DESIGNŌĆØ MD. ASIF RAHMAN 10.01.03.108 DEPT. OF CE

- 2. SLAB Slabs are an important structural component where prestressing is applied. Slabs are used to provide flat or useful surfaces.

- 4. ONE WAY SLAB One-way slabs are those slabs with an aspect ratio in plan of 2:1 or greater, in which bending is primarily about the long axis. So, the slab is one way where L/B Ōēź 2.

- 5. SOLID HOLLO W RIBBE D TYPES OF ONE WAY SLAB One way slab may beŌĆ”

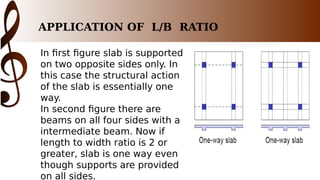

- 6. APPLICATION OF L/B RATIO In first figure slab is supported on two opposite sides only. In this case the structural action of the slab is essentially one way. In second figure there are beams on all four sides with a intermediate beam. Now if length to width ratio is 2 or greater, slab is one way even though supports are provided on all sides.

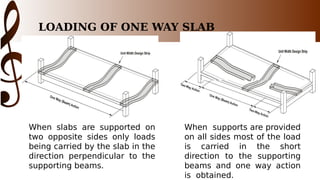

- 7. LOADING OF ONE WAY SLAB When slabs are supported on two opposite sides only loads being carried by the slab in the direction perpendicular to the supporting beams. When supports are provided on all sides most of the load is carried in the short direction to the supporting beams and one way action is obtained.

- 8. DESIGN & ANALYSIS For analysis there is a term asŌĆ”. ŌĆ£ONE WAY SLAB IS A SET OF A RECTANGULAR BEAMS SIDE BY SIDEŌĆØ But How ??? Lets find itŌĆ”..

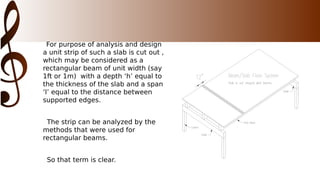

- 9. For purpose of analysis and design a unit strip of such a slab is cut out , which may be considered as a rectangular beam of unit width (say 1ft or 1m) with a depth ŌĆśhŌĆÖ equal to the thickness of the slab and a span ŌĆślŌĆÖ equal to the distance between supported edges. The strip can be analyzed by the methods that were used for rectangular beams. So that term is clear.

- 10. ACI CODE SPECIFICATIONS For design purposes there are some ACI code specifications. Such asŌĆ”..

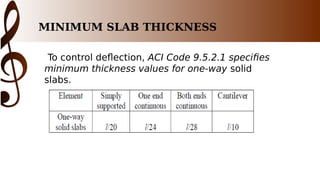

- 11. MINIMUM SLAB THICKNESS To control deflection, ACI Code 9.5.2.1 specifies minimum thickness values for one-way solid slabs.

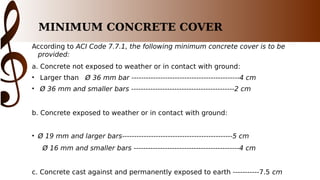

- 12. MINIMUM CONCRETE COVER According to ACI Code 7.7.1, the following minimum concrete cover is to be provided: a. Concrete not exposed to weather or in contact with ground: ŌĆó Larger than ├ś 36 mm bar ---------------------------------------------4 cm ŌĆó ├ś 36 mm and smaller bars -------------------------------------------2 cm b. Concrete exposed to weather or in contact with ground: ŌĆó ├ś 19 mm and larger bars----------------------------------------------5 cm ├ś 16 mm and smaller bars --------------------------------------------4 cm c. Concrete cast against and permanently exposed to earth -----------7.5 cm

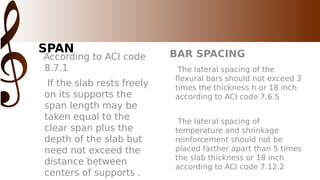

- 13. SPAN According to ACI code 8.7.1 If the slab rests freely on its supports the span length may be taken equal to the clear span plus the depth of the slab but need not exceed the distance between centers of supports . BAR SPACING The lateral spacing of the flexural bars should not exceed 3 times the thickness h or 18 inch according to ACI code 7.6.5 The lateral spacing of temperature and shrinkage reinforcement should not be placed farther apart than 5 times the slab thickness or 18 inch according to ACI code 7.12.2

- 14. MAXIMAM REINFORCEMENT RATIO REINFORCEMENT RATIO : Reinforcement ratio is the ratio of reinforcement area to gross concrete area based on total depth of slab. One-way solid slabs are designed as rectangular sections subjected to shear and moment. Thus, the maximum reinforcement ratio corresponds to a net tensile stain in the reinforcement, Ōé¼t of 0.004

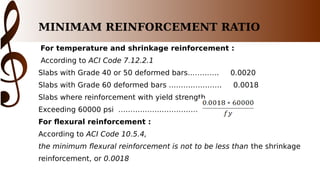

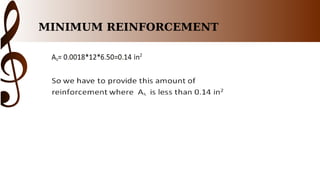

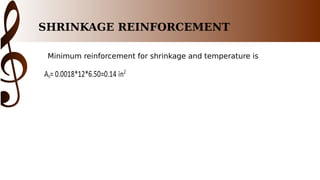

- 15. MINIMAM REINFORCEMENT RATIO For temperature and shrinkage reinforcement : According to ACI Code 7.12.2.1 Slabs with Grade 40 or 50 deformed barsŌĆ”ŌĆ”ŌĆ”ŌĆ”. 0.0020 Slabs with Grade 60 deformed bars ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”. 0.0018 Slabs where reinforcement with yield strength Exceeding 60000 psi ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”ŌĆ”..... For flexural reinforcement : According to ACI Code 10.5.4, the minimum flexural reinforcement is not to be less than the shrinkage reinforcement, or 0.0018

- 16. EXAMPLE PROBLEM A reinforced concrete slab is built integrally with its supports and consists of equal span of 15 ft. The service live load is 100 psf and 4000 psi concrete is specified for use with steel with a yield stress equal to 60000 psi. Design the slab following the provisions of the ACI code.

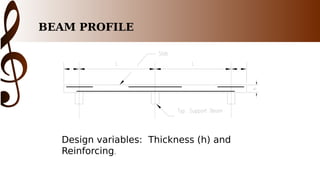

- 17. BEAM PROFILE Design variables: Thickness (h) and Reinforcing.

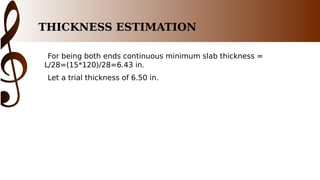

- 18. THICKNESS ESTIMATION For being both ends continuous minimum slab thickness = L/28=(15*120)/28=6.43 in. Let a trial thickness of 6.50 in.

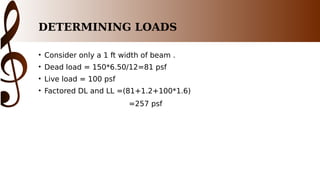

- 19. DETERMINING LOADS ŌĆó Consider only a 1 ft width of beam . ŌĆó Dead load = 150*6.50/12=81 psf ŌĆó Live load = 100 psf ŌĆó Factored DL and LL =(81+1.2+100*1.6) =257 psf

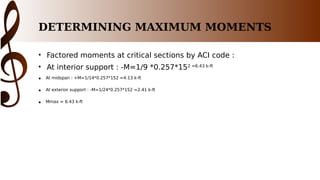

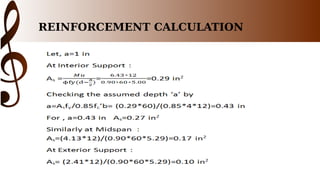

- 20. DETERMINING MAXIMUM MOMENTS ŌĆó Factored moments at critical sections by ACI code : ŌĆó At interior support : -M=1/9 *0.257*152 =6.43 k-ft ŌĆó At midspan : +M=1/14*0.257*152 =4.13 k-ft ŌĆó At exterior support : -M=1/24*0.257*152 =2.41 k-ft ŌĆó Mmax = 6.43 k-ft

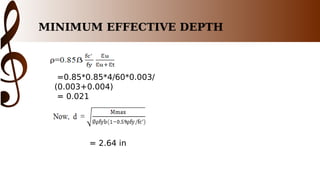

- 21. MINIMUM EFFECTIVE DEPTH =0.85*0.85*4/60*0.003/ (0.003+0.004) = 0.021 = 2.64 in

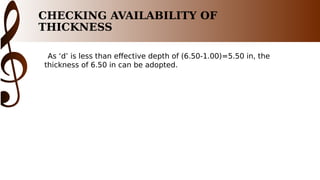

- 22. CHECKING AVAILABILITY OF THICKNESS As ŌĆśdŌĆÖ is less than effective depth of (6.50-1.00)=5.50 in, the thickness of 6.50 in can be adopted.

- 25. SHRINKAGE REINFORCEMENT Minimum reinforcement for shrinkage and temperature is

- 26. FINAL DESIGN

- 27. LAYOUT OF ONE WAY SLAB

- 28. Provides useful flat surface One way slab may be used when there is architectural limitations It is the simplest form of slab design Main reinforcement placing is one way, so there is a little congestion than two way slab APPLICATION OF ONE WAY SLAB