Weldability

- 2. Mr. MUBASSIR I. GHONIYA of Mechanical Engineering. Enrolment No. 136010319024 has Satisfactorily completed his term work in F.T for the ending in APRIL 2016. Date :- Guide H.O.D Sign Sign

- 4. DEFINITION OF WELDABILITY ÔÅØ Two metallic parts of same or different metals mixed and fused when welded with or without applying pressure, with or without use of filler metal then the ease with wich the metal joint will properly of joining metal or metals called weldability ÔÅØ The easy with which welding of a give material can be done without producing any defect is called weldability. ÔÅØ Also be defined as the capability of a metal to be welded under the fabrication conditions imposed satisfactorily in the intended surface.

- 6. MEANING OF WELDABILITY ÔÅØ Weldability is considered as ease of accomplishing a satisfactory weld joint and can be in determined from quality of the weld joint, effort and cost required for developing the weld joint. ÔÅØ While efforts required for producing sound weld joint are determined by properties of metal system in consideration namely melting point, thermal expansion coefficient, thermal and electrical conductivity, defects inherent in base metal and surface condition. ÔÅØ Therefore, weldability of a metal is considered as a relative term.

- 7. ÔÅØ The metallic material with adequate weldabilityshoud fulfill the requirements like, A. The metallic material with adequate weldabilityshoud fulfill the requirements like, B. Contribute to good weld quality even with high dulation. C. Have unchanged corrosion resistance after welding. D. Should not be embrittled when stress relieving.

- 8. CONCEPT OF WELDABILTY The concepts of weldability are, 1. Metallurgical compatibility of a metalalloy to be welded with any specific welding process. Metallurgical compatibility means that the base metal and weld metal can be combined with the degree of dilution encountered in a specific process without the production of deliteriousconstituens and phases. 2. Ability of the metalalloy to be welded with mechanical soundness. The mechanical soundness must meets soundness requirments and normal engeeniring standards.

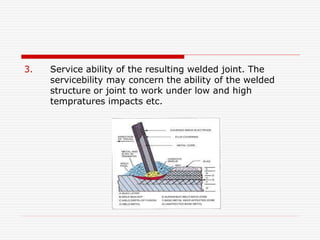

- 9. 3. Service ability of the resulting welded joint. The servicebility may concern the ability of the welded structure or joint to work under low and high tempratures impacts etc.

- 10. FACTORS AFFECTING ON WELDABILITY ÔÅØ Meting point of metal: Materials with medium melting point can be welded very easily. ÔÅØ Thermal conductivity: Material with high thermal conductivity (K) is treated as difficult to weld materials. ÔÅØ Reactivity: If the material reacts with air, water or surroundings it become difficult to weld. ÔÅØ Coefficient of thermal expansion of metals: Material with high thermal expansion coefficient, it becomes difficult to weld. ÔÅØ Electrical resistance: Higher the electrical resistance of the material, it becomes difficult because it requires lot of heat energy.

- 11. ÔÅØ Surface condition: The material with dirty surface it becomes difficult to weld. ÔÅØ Strength and brittleness of metal at high pressure. ÔÅØ Composition of metal. ÔÅØ Heat treatment carrying out before and after welding. ÔÅØ Thermal properties of the metals. From the above mentioned factors whichever the material is influenced by maximum number of factors, the corresponding material is treated as very difficult to weld and whichever the material is influenced by least number of factors, the corresponding material is treated as very easy weld material.

- 12. THE WELDABILITRY OF SOME METALS IN DESCENDING ORDER IS AS UNDER. 1. IRON 2. STEEL 3. CAST IRON 4. LOW ALLOY STEEL 5. STAINLESS STEEL

- 13. IMPORTANCE OF WELDABILITY 1. As per the weldability of base metal and electrode metal mechanically sound weld joint without crack and produced. therefore to satisfy the needs of design. 2. weldability is an important quality. The fabrication work is done using the metals having good weldability can give strength of joint as per the design of the joint. 3. If weldability of the metals is good then special type of welding process are not required to weld a metal. 4. The weld obtained by selecting metal having good weldability does not produced brittle fracture. 5. Good weldability reduces the requirement of preheating.

- 14. 6. Weldability shows their capability to provide service as per the design of the joint.