Why Safeguard Industrial Machinery?

- 1. Rockford Systems, LLC CORPORATE OVERVIEW

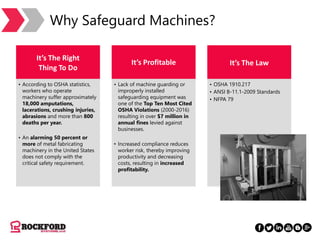

- 2. Why Safeguard Machines? ItŌĆÖs The Right Thing To Do ŌĆó According to OSHA statistics, workers who operate machinery suffer approximately 18,000 amputations, lacerations, crushing injuries, abrasions and more than 800 deaths per year. ŌĆó An alarming 50 percent or more of metal fabricating machinery in the United States does not comply with the critical safety requirement. ItŌĆÖs Profitable ŌĆó Lack of machine guarding or improperly installed safeguarding equipment was one of the Top Ten Most Cited OSHA Violations (2000-2016) resulting in over $7 million in annual fines levied against businesses. ŌĆó Increased compliance reduces worker risk, thereby improving productivity and decreasing costs, resulting in increased profitability. ItŌĆÖs The Law ŌĆó OSHA 1910.217 ŌĆó ANSI B-11.1-2009 Standards ŌĆó NFPA 79

- 3. OSH Act of 1970 ŌĆó Under the OSH Act of 1970, employers are responsible for providing a safe and healthful workplace. Employers must comply with all applicable OSHA standards. Employers must also comply with the General Duty Clause of the OSH Act, which requires employers to keep their workplace free of serious recognized hazards. ŌĆó By law, employers are legally required to follow OSHA regulations. That means an OSHA inspector will issue citations for noncompliance to their CFR (Code of Federal Regulations). OSHAŌĆÖs CFR SubPart OŌĆöMachinery and Machine Guarding has six (6) machine specific safeguarding regulations which are: ŌĆó 1910.213 Woodworking Machinery ŌĆó 1910.214 Coope rage Machinery ŌĆó 1910.215 Abrasive Wheel Machinery ŌĆó 1910.216 Mills and Calendars ŌĆó 1910.217 Mechanical Power Presses ŌĆó 1910.218 Forging Machines

- 4. OSH Act of 1970 (continued) ŌĆó OSHA regulations for safeguarding most other machines falls under 1910.212 General Requirements For All Machines which specifies that the operator and others in the machine area be protected from exposure to hazards. ŌĆó However, ANSIŌĆÖs B11-Series Safety Standards (which has 24 machine categories) are often used to fill in the details for specific safeguarding and can be used as reference material by OSHA inspectors. Even though ANSI safety standards are voluntary, they could become legally mandatory if an OSHA citation mentions specific ANSI standard for you to comply to. ŌĆó The bottom line is that all employers should strive to exceed minimum OSHA requirements and abide by the best safety practices found in the ANSI B11 standards.

- 5. OSHA Inspection Priorities Since OSHA cannot inspect all 7 million workplaces it covers each year, the agency focuses its inspection resources on the most hazardous workplaces in the following order of priority (OSHA Fact Sheet DEP FS-3783): ŌĆóHazards that could cause death or serious physical harm receive top priority. Compliance officers will ask employers to correct these hazards immediately or remove endangered employees. Imminent danger situations ŌĆóEmployers must report: ŌĆóAll work-related fatalities within 8 hours; ŌĆóAll work-related inpatient hospitalizations, amputations, or losses of an eye within 24 hours Severe Injuries and Illnesses ŌĆóAllegations of hazards or violations also receive a high priority. Employees may request anonymity when they file complaints. Worker Complaints ŌĆóOf hazards from other federal, state or local agencies, individuals, organizations or the media receive consideration for inspection. Referrals ŌĆóInspections aimed at specific high-hazard industries or individual workplaces that have experienced high rates of injuries and illnesses also receive priority. 1.Targeted Inspection ŌĆóChecks for abatement of violations cited during previous inspections are also conducted by the agency in certain circumstances. 1.Follow-Up Inspection Normally, OSHA conducts inspections without advance notice.

- 6. Common Safeguarding Misperceptions ŌĆó Myth #1: New machines are safe because their manufacturers designed and built them to meet up-to-date safety standards and regulations ŌĆō REALITY: Not necessarily ŌĆó Always conduct an Onsite Risk Assessment and/or Onsite Machine Survey to identify OSHA 1910.212 ŌĆ£General Requirements for MachinesŌĆØ violations and identify how to bring machines into compliance. ŌĆó ANSI, Canadian and European standards often provide ŌĆ£Best Practices.ŌĆØ

- 7. Common Safeguarding Misperceptions ŌĆó Myth #2: Older machines are "grandfathered inŌĆØ since they were designed and manufactured before safety standards and regulations existed ŌĆō REALITY: False, there are no grandfathering laws in effect. All machines must meet minimum OSHA regulations. For companies wanting to meet a higher safety benchmark, ANSI B11 Safety Standards offer the best available guidelines for metal processing machines.

- 8. Common Safeguarding Misperceptions ŌĆó Myth #3: Automation cells containing Industrial Robot are always properly safeguarded by the robot supplier - REALITY: May not be true, some OEMŌĆÖs provide this and some do not

- 10. Rockford Systems Overview ŌĆó Private company, founded in 1971 ŌĆó Headquartered in Rockford, Illinois ŌĆó Acquired by Randolph Group (Chicago, Illinois) in 2014 ŌĆó Deliver trusted machine safeguarding solutions for organizations working with industrial machinery ŌĆó Help organizations interpret and apply complex Occupational Safety and Health Administration (OSHA) regulations and American National Standards Institute (ANSI) machine safety standards for a broad array of industrial applications ŌĆó Provide complete Machine Safety Life-Cycle Management Solutions ŌĆó Improved the profitability of many of North AmericaŌĆÖs largest companies by increasing compliance, reducing worker risk, increasing productivity and decreasing costs Rockford Systems, LLC 4620 Hydraulic Road Rockford, IL 61109 1-800-922-7533 1-815-874-7891 Rockford Systems, LLC 4617 American Road Rockford, IL 61109 Rockford Systems, LLC 4585 American Road Rockford, IL 61109 Our Trusted Safeguarding Solutions Exceed OSHA Regulations and ANSI Standards

- 12. Our Markets

- 13. Our Clients

- 14. Organization Structure Randolph Group Joe Nitiss, CEO Matt Brenner, VP of Sales Nick Zimmer, Central Region Manager Tom Hendryx, Western Region Manager Phil Reuter, Eastern Region Manager Ryan Kaltenbrun/Matt Brenner, Southern Region Manager Sheryl Broers, Inside Sales Manager Roger Harrison, Director of Training Carrie Halle, VP of Marketing Brian Boes, VP of Engineering & Operations Ken Kranz, VP of Finance & Administration

- 15. Industry Leadership ŌĆó Employee leadership: ŌĆō ANSI B11.0 Committee ŌĆō ANSI B11-19 Writing Committee

- 17. What is Machine Safety Life-Cycle Management? ŌĆó Delivering trusted machine safeguarding solutions that help keep your workers safe and increase your companyŌĆÖs profitability ŌĆó Rockford Systems provides complete Machine Safety Life-Cycle Management Solutions, including: ŌĆó onsite risk assessments ŌĆó onsite machine surveys ŌĆó customized engineered design solutions ŌĆó over 10,000 safeguarding products ŌĆó installation and integration services ŌĆó safety education and training ŌĆó technical and in-field support ŌĆó ongoing compliance validation

- 18. Safeguarding Standards are Complex & Changing

- 19. Industry Leading Safety Education ŌĆó Objective: Help safety personnel interpret and apply OSHA Regulations and ANSI Standards for a broad array of industrial applications. Attendees will learn to keep their companies in absolute compliance, reduce insurance costs, and help prevent employee accidents on metal working machinery, such as power presses and press brakes. ŌĆó Format: Monthly 2 ┬Į day seminars combine classroom discussion with live demonstrations on a number of machines to give attendees for a practical, hands-on learning experience. ŌĆó Target Audience: Safety personnel in Health & Safety, Human Resources, Operations, Manufacturing, Engineering and Insurance, Risk Management ŌĆó Information Covered: Occupational Safety and Health Administration (OSHA) 29 CFR regulations and American National Standards Institute (ANSI) B-11 series machine safety standards. ŌĆó Instructor: Roger Harrison, an industrial safeguarding expert with over 25,000 hours of training experience. Mr. Harrison is also a speaker at seminars sponsored by the Precision Metal Forming Association (PMA) and FABTECH. Past Seminar Attendees: A.O. Smith, Alcoa, Arizona State University, Ball Corporation, Boeing, Borg Warner, Briggs & Stratton, CNA Insurance, Caterpillar, Coleman Outdoor Products, ConAgra Foods, Delco Remy, Eaton Corp, Ford Motor Company, General Dynamics, General Electric, General Motors, Georgia Tech, GKN Aerospace, Goodrich UTC Aerospace, Harley Davidson, Herman Miller, Hill-Rom, Honda, Honeywell, J.I. Case, John Deere, Lazy Boy, Liberty Mutual Insurance, Lippert Components, Lockheed Martin Aeronautics, Martin Marietta, Monroe Auto Equipment, Motorola, Navistar, Otis Elevator, Pratt Whitney, Purdue University, Rockwell Automation, Samsonite, Skorsky Aircraft, Square D, Stanley Bostitch, Steelcase, Stoughton Trailer, Sub Zero Freezer, Textron Gulf & Turf, Travelers Insurance, True Manufacturing, TRW, UT Automotive, Whirlpool, Zurich Insurance and many more.

- 20. Safeguarding Seminar Agenda Day One ŌĆó Welcome, Introduction, and Objectives of Seminar ŌĆó Brief History of ANSI, OSHA, and NFPA-79 ŌĆó Risk Assessment/Risk Reduction ŌĆó OSHA 29 CFR 1910.211, Definitions ŌĆó OSHA 29 CFR 1910.212, General Requirements for All Machines and Auxiliary Equipment ŌĆó OSHA 29 CFR 1910.217 Mechanical Power Presses ŌĆó ANSI B11.1-2009 Mechanical Power Presses ŌĆó Full-Revolution-Clutch Identification and Control Requirements ŌĆó Part-Revolution-Clutch Identification and Control Requirements ŌĆó Control Reliability and Brake Monitoring ŌĆó Electrical Component Requirements (NFPA-79) ŌĆó Hand-Feeding Tools ŌĆó Point-Of-Operation SafeguardingŌĆöGuards, Devices, Methods ŌĆó Design, Construction, Setting, and Feeding of Dies ŌĆó Inspection and Maintenance Records ŌĆó Instruction to Operators ŌĆó Reports of Injuries ŌĆó Mechanical Power-Transmission Apparatus (OSHA 1910.219) Day Two ANSI B11.2 Hydraulic Power Presses ANSI B11.3 Power Press Brakes ANSI B11.4 Shears ANSI B11.5 Iron Workers ANSI B11.6 Lathes (Manually Operated) ANSI B11.7 Cold Header and Cold Formers ANSI B11.8 Drilling, Milling, and Boring Machines ANSI B11.9 Grinding Machines ANSI B11.10 Metal Sawing Machines ANSI B11.11 Gear Cutting Machines ANSI B11.12 Roll Forming and Roll Bending Machines ANSI B11.13 Automatic Screw/Bar and Chucking Machines ANSI B11.14 Coil Slitting Machines/Systems WithdrawnŌĆöSee ANSI B11.18 ANSI B11.15 Pipe, Tube, and Shape Bending Machines ANSI B11.16 Metal Powder Compacting Presses ANSI B11.17 Horizontal Hydraulic Extrusion Presses ANSI B11.18 Coil Processing Systems ANSI B11.19 Safeguarding Methods (Criteria) ANSI B11.20 Integrated Manufacturing (Cells) ANSI B11.21 Machine Tools Using Laser Processing (Cutting) ANSI B11.22 CNC Turning Centers and Lathes ANSI B11.23 Machining CentersŌĆöCNC Mills, Drills, Boring ANSI B11.24 Transfer Machines ANSI/SPI B151.1 Horizontal (Plastic) Injection Molding Machines BS ISO 14137 and JIS B6360 Electrical Discharge (EDM) Machines ANSI B152.1 Hydraulic Die Casting Presses ANSI/RIA R15.06ŌĆō1999 & 2012 Robots and Large Work Envelopes OSHA 1910.147 Control of Hazardous Energy Lockout/Tagout

- 21. Onsite Risk Assessments ŌĆó Objective: Identification of machinery tasks and risk scoring of hazards using the ANSI B11.0-2015 safety standard methods. ŌĆó Format: A Risk Assessment Specialist will visit your plant(s) and go through the Risk Assessment Process (shown at right), which could take days, weeks or months. ŌĆó Target Audience: Safety personnel in Health & Safety, Human Resources, Operations, Manufacturing, Engineering and Insurance, Risk Management. ŌĆó Information Covered: All applicable OSHA, ANSI, and NFPA regulations and standards will be considered during the machine review. Based on the assessment findings, the risk rankings will be calculated. In addition, suggested guarding changes will be made and potential risk ranking improvements calculated. Detailed documentation will be provided.

- 22. Risk Assessment Process An Onsite Risk Assessment will identify the task and associated hazards on your machinery and score the risk level using the ANSI B11.0-2015 safety standard methods. All applicable OSHA, ANSI, and NFPA regulations and standards will be considered during the machine review. Pre-Assessment Meeting ŌĆóDiscuss the risk assessment process, set the scope of the project, and discuss the ŌĆ£acceptable or tolerableŌĆØ risk perceptions. ŌĆóThe presence of an electrician and experienced machine operator will be required. Identify Hazards & Who Is At Risk ŌĆóDetailed assessment forms and photo documentation will be used to identify the personnel tasks, identify the hazards, gather all applicable machine component and operational information necessary to determine the current machine risk ranking level. Assess Hazard Level ŌĆóSeverity of Injury: An evaluation of the injury severity (or consequences) of each possible hazard and rank order them by severity of the outcome will be done. ŌĆóExposure Frequency: The exposure frequency is the number of times personnel (while performing a task) are exposed to a hazard in a given time period. Evaluations of the current engineered controls will be made in order to establish the exposure rate. ŌĆó Avoidance Likelihood: The possibility of avoiding a hazard can be tied to the machinery or process design. Post-Assessment Meeting ŌĆóDiscuss the findings, explain the preliminary risk rankings, discuss possible ways of reducing the risk rankings, and discuss the time frame for completion of the detailed assessments and summary file. Implement Controls & Reassess ŌĆóRecommended next step is the Onsite Machine Survey to identify specific solutions and costs to bring hazards into compliance.

- 23. Onsite Machine Surveys ŌĆó Our professional personnel will visit your site(s) to conduct full machine safety surveys and evaluate safety concerns. ŌĆó Detailed Machine Safety Surveys: ŌĆō For updating machinery to meet or exceed current safety regulations and standards (OSHA, ANSI B11 series, NFPA 79) or your corporate guidelines ŌĆō Thorough surveys conducted by qualified safeguarding specialists, using rapid Mobile Inspection tool ŌĆō Report-proposals generated after machine safety survey conducted ŌĆō Experience with all project sizes ŌĆō Experience working with all company sizes ŌĆō Experience working all machine types, from the very old to the very new ŌĆō Reputation as Industry Leader

- 24. Customized Engineered Design Solutions ŌĆó Many machine safeguarding projects identified in the Onsite Machine Survey require customized, engineered design solutions that integrate seamlessly into your companyŌĆÖs machines, plants and operations. Engineering reviews the customer-supplied electrical and hydraulic machine schematics, evaluates existing interfaces or controls for compliance, and identifies need for special interface or controls. ŌĆó From there, Rockford Systems delivers customized engineered and automated safety device interfaces or specialized machine controls manufactured to your exact size requirements and automated to reduce operator fatigue. In addition, detailed electrical and hydraulic schematics and Bills of Material (BOMs) are provided for compliance tracking and future parts ordering. ŌĆó All engineered design solutions meet or exceed all OSHA, ANSI and NFPA 79 standards for machine and operator safety. Experts in their field, Rockford Systems provides industry leadership on the ANSI B11.0 Committee and ANSI B11-19 Writing Committee and trusted, quality engineering solutions to many of North AmericaŌĆÖs largest companies.

- 25. Customized, Engineered Solutions Process Identify Need Machines that need a customized safeguarding interface or control are identified in the Onsite Machine Survey and routed for Engineering Design Customization Evaluate Solution(s) Engineering reviews the customer- supplied electrical and hydraulic machine schematics, evaluates existing control for compliance, identifies need for special interface or controls Delivering Solution(s) Designing customized engineered and automated safety device interfaces or specialized machine controls

- 26. Machine Safeguarding Products ŌĆó Our line of over 10,000 machine safety products allows industry to meet or exceed the OSHA and ANSI standards for machine guarding: ŌĆó Catalog Items Including Safety Shields, Safety Signs, Safety Gauges, Motor Controls ŌĆó Custom Items Including Barrier Guards, Light Curtains, Laser Scanners, Laser Devices, Safety Mats, Press and Press Brake Controls ŌĆó EX-ALŌäó Proprietary Barrier and Perimeter Guarding Systems ŌĆó Auxiliary Safeguarding ŌĆó Die-blocks and Accessories ŌĆó Disconnects and Starters ŌĆó Guard Opening Scales ŌĆó LED Industrial Lighting ŌĆó Lockout/Tagout Equipment ŌĆó Machine Safeguarding Devices ŌĆó Perimeter Guarding ŌĆó Safety Interlock Switches ŌĆó Palm Button Assemblies ŌĆó Safety Light Curtain Systems ŌĆó Safety Shields ŌĆó Training Aids

- 27. Quality Installation & Integration Services ŌĆó The Rockford Systems installation crews are highly skilled and trained, with a background in electrical engineering and many hours of on-the-job experience on all types of equipment. ŌĆó Rockford Systems installation crews provide complete integration and installation services in your plant or instruct your installation personnel on best practices. Installation crews integrate safety devices into sophisticated machine controls that meet or exceed all OSHA regulations and ANSI/NFPA standards. ŌĆó Installation crews also engineer and install minor modifications on the spot that might be required to improve operator usability and/or reduce operator fatigue. ŌĆó All installations conclude with operator safety training on the correct use of the new machine safeguarding equipment. In addition, safety training helps operators understand how to remain safe while also maximizing productivity.

- 28. Responsive Technical Support and In-Field Service ŌĆó Every purchase and installation is backed up with a professional, high-trained team of advisors: ŌĆō Technical Service Advisors available for emergency troubleshooting ŌĆō In-Field Service Technicians available for troubleshooting and repairs ŌĆō In-House Warranty and Non-Warranty Repairs Our Commitment To Machine and Operator Safety Never Ends

- 29. Ongoing Compliance Validation ŌĆó An optional annual maintenance contract. ŌĆó Ensure that safeguarding products are working at optimal performance. ŌĆó Ensure that operators are using safeguarding solutions as designed and trained.

- 31. Results ’ā╝ Increased OSHA and ANSI compliance ’ā╝ Reduced worker risk ’ā╝ Increased productivity ’ā╝ Decreased costs ’ā╝Improved profitability

- 32. Summary ŌĆó As a trusted advisor since 1971, Rockford Systems helps organizations interpret and apply complex OSHA regulations and ANSI machine safety standards for a broad array of industrial applications. ŌĆó In addition, Rockford provides complete Machine Safety Life-Cycle Management Solutions, ranging from Onsite Risk Assessments to Ongoing Compliance Validation. ŌĆó Rockford Systems has improved the profitability of many of North AmericaŌĆÖs largest companies by increasing compliance, reducing worker risk, increasing productivity and decreasing costs.

- 33. SAFEGUARDING ROI

- 34. What does a machine accident cost? ŌĆó Insurance studies indicate machine safeguarding provides an opportunity for businesses to reduce bottom-line operating costs by eliminating both the direct and indirect costs of an accident, while improving productivity and employee morale. ŌĆó Liberty Mutual reported in its annual Workplace Safety Index that U.S. employers spent $48.6 billion for wage and productivity losses, medical expenses and administrative expenses for workers hurt on the job. ŌĆō This is roughly equivalent to the annual sales of Cisco, Pfizer or FedEx. ŌĆó A study by Colorado State University set the total direct and indirect cost of workplace injuries at a staggering $128 billion.

- 35. Direct Costs ŌĆó Direct costs of an accident refer to out-of-pocket expenses like hospital and medical bills. ŌĆó They also include the loss of a workerŌĆÖs time because of the accident, the lost productivity by the machine involved in the accident being idled or requiring repairs, as well as the other machines further down the production line being shut down. ŌĆó Costs continue to cascade throughout the company with overtime required to make up the lost productivity and new workers who need to be hired and trained. ŌĆó The National Safety Council (NSC) estimates that lost time alone associated with the average injury costs nearly $30,000.

- 36. Indirect Costs ŌĆó Analysis of most accidents reveal that the actual total cost can range from 4x to 10x times the visible, direct cost stated by an insurance company. ŌĆó For example, a single accident can result in OSHA fines up to $100,000 per machine or more if the violation is found to be willful. ŌĆō In 2010, 24 percent of OSHAŌĆÖs Top 10 citations for manufacturing dealt with machine guarding violations, resulting in more than $6 million in proposed penalties. ŌĆó In addition, insurance rates can rise dramatically or coverage can be dropped entirely. ŌĆó Investments targeted for company growth may need to be diverted to cover the costs of the accident, while employee morale and productivity can experience a significant drop ŌĆó The companyŌĆÖs brand and reputation will likely be damaged by negative publicity. ŌĆó Legal fees, plus management time spent dealing with regulators and attorneys. ŌĆó And while it is not calculated as an indirect cost, a poor safety record can make the difference between a company winning and losing bids, especially with government contracts. A plant with a singularly bad reputation for safety may also find itself unable to attract workers at all or may have to pay wages well above market value to do so. ŌĆó Also, if the machine where a serious accident occurred is unique and is locked out for investigation or until the safeguarding deficiency is abated, the company may need to outsource the work at a much higher cost. ItŌĆÖs also possible that the work is so specialized that itŌĆÖs impossible to outsource and therefore the company loses the business.

- 37. Do The Math ŌĆó OSHAŌĆÖs $afety Pays website (www.osha.gov/dcsp/smallbusiness/safetypays) makes it easy for organizations to calculate direct and indirect costs of an accident. ŌĆó As an example, letŌĆÖs assume a fictional company with annual sales of $5 million and an 8% pre-tax profit margin has an accident involving an employee whereby his hand was entangled in a drill press. ŌĆó By using insurance company claims data, $afety Pays can calculate that the crushing accident will cost that company, on average: ŌĆō Direct Cost: $56,557 ŌĆō Indirect Cost: $62,212 ŌĆō Estimated Total Cost: $118,769 ŌĆó By entering profit margin information, $afety Pays will also project the additional sales required to recover the costs of the injury. In this instance, additional sales revenue necessary to cover costs is $1,484,612 based on the 8% profit margin or approximately one third of annual sales. If pre-tax margins are less, the sales impact is even greater. ŌĆó On the other side of the ledger is the cost to safeguard the machine involved in the accident. For the purpose of this discussion, letŌĆÖs assume that the same fictional company had an onsite risk assessment performed by a reputable firm that surveyed ten machines on the plant floor at a cost of $5,000, or $500 per machine. Next, assume that the drill press had been safeguarded per OSHA regulations and ANSI standards at a total cost of $1,000. ŌĆó Adding in its prorated share of the risk assessment, total cost to safeguard the drill press would be $1,500, a figure that compares very favorably to the estimated $118,769 cost of the accident.