Wiggins Service Systems Catalog

- 1. The Leader in Fueling Systems Since 1967 WORKFASTER,CLEANER,SAFER

- 2. aboutus 2 www.fastfueling.com History & Innovation By 1967, when we entered the off highway market, Wiggins connec- tors was already recognized throughout the aerospace industry as an innovator in fueling systems. With over 45 years of experience in high quality refueling systems, AdelWiggins Group has the con- nectors, nozzles, receivers and vents to make your fleet as efficient and safe as possible. As a leader in the field of highly engineered aerospace components, we have leveraged our knowledge to successfully develop high quality parts to support the mining and construction industry. Leading the way with new products, in 1972 we introduced the ZZ9A nozzle, part of the fast, clean and efficient refueling which has become virtually an industry standard today. Following up on that success, we made a more reliable, lighter and faster fu- eling nozzle, the ZZ9A1. And now, we are introducing the new Wiggins noz- zle, ZZ9A2 and the new JNX receiver with the JVX vent; the industryŌĆÖs safest and most reliable refueling system.

- 3. 3323.881.7601 ŌĆó Fax: 323.981.7301 Contact Us Wiggins Service Systems 5000 Triggs Street, Los Angeles, CA 90022 323.269.9181 Ō¢Ā Fax: 323.269.3759 www.fastfueling.com Sales Administrator | Katrina Ureno, kureno@adelwiggins.com, 323.881.7601 Distribution Manager | Dave Martin, dmartin@adelwiggins.com, 323.881.7646 Business Unit Manager | Mario Pantuso, mpantuso@adelwiggins.com, 323.881.7637 Technical Support | Chris Quang, cquang@adelwiggins.com, 323.881.7667

- 4. non-pressurizing 4 www.fastfueling.com The JNX Series Non-Pressurizing Fast Fueling System Fast, Clean, and ULTRA SAFE Introduction The Wiggins JNX non pressurizing system allows for automatic diesel refueling at up to 211 gpm (800 lpm) with existing Wiggins nozzles and does not pressurize the fuel tank. Shutoff is automatic, fully self contained, and cannot be overridden. JNX offers top line quality, performance, and reliability at a competitive price. CompetitorsŌĆÖ Non Pressurizing Systems Competitors' non pressurizing systems use float valves and are FAIL OPEN systems. They will overfill and pressurize the fuel tank if fueling is carried out with a faulty float valve or bleed hose. (Competitors' systems commonly make use of an internal bleed hose, which is vulnerable to fatigue due to fuel slosh.) In this situation, fuel continues to bleed through the faulty float valve or hose even when the fuel level has passed the required shutoff point, preventing pressure from equalizing across the shutoff piston. The pressure imbalance keeps the piston open, and fuel continues to flow into the tank unchecked. Consequently, the tank overfills and is pressurized in proportion to the flow rate ŌĆō the higher the flow rate, the greater the spillage and pressure build up ŌĆō creating a potentially severe safety and environmental hazard. The Wiggins ULTRA SAFE JNX System The Wiggins JNX system represents a technological leap forward in non pressurizing automatic diesel refueling systems. The JNX system uses conventional pressure sensitive fuel nozzles such as the Wiggins ZZ9A1 and ZZ9A2 while providing users with unique FAIL SHUT and OVERFILL RESISTANT features not matched by the competition. The Wiggins JNX shutoff valve is FAIL SHUT: the spring closed main valve can only be opened by a pressure signal from the jet level sensor ŌĆō if for any reason the pressure signal is lost, the main valve will close, shutting off the flow of fuel into the tank. This ensures that overfilling the tank is not possible even if any part of the jet level sensor or signal hose were to fail. The unique Wiggins jet level sensor does not have any moving parts to wear out and is thus extremely reliable. The Wiggins non pressurizing system uses only external signal hoses, making JNX easy to install and maintain. The JNX system is available in both direct and remote fill configurations.

- 5. When the pressure signal is cut o’¼Ć by the rising fuel level, the JNX valve closes, which also triggers the fuel nozzle to shut o’¼Ć, and fueling is stopped When the fuel level is higher than the jet level sensor, the jet is interrupted, cuŲ½ng o’¼Ć the pressure signal to the JNX valve 5323.881.7601 ŌĆó Fax: 323.981.7301 How It Works Fuel ’¼éows through the signal hoses and jet level sensor, creaŲ¤ng a pressure signal to open the JNX valve and allow fuel into the tank During fueling, the jet level sensor is uninterrupted and allows fueling to conŲ¤nue AutomaŲ¤c Shuto’¼Ć Valve (JNX 01 02 25 shown) Refueling Nozzle (ZZ9A2 shown) Jet Level Sensor/Vent (JVX shown) 0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 0 5 10 15 20 25 30 35 40 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 Flow Rate (lpm) PressureDrop(psi) Flow Rate (gpm) JNX System Pressure Drop vs. Flow Rate (ZZ9A2 nozzle connected to JNX-01-02) *Note: actual pressure drop will vary based on ’¼éuid density and viscosity.

- 6. X 6 www.fastfueling.com non-pressurizing JNX-01-02 ŌĆó Standard automatic shutoff valve ŌĆó ZN2 style receiver interface to mate with ZZ9A1 or ZZ9A2 nozzle ŌĆó 2" NPT male thread for mounting to tank ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate Min. Flow Rate 25 gpm (95 lpm) Max. Flow Rate 211 gpm (800 lpm) Operating Pressure 75 psig (520 kPa) Weight 3.33 lbs (1.51 kg) Automatic ShutoffValves JNX-01-02-25 ŌĆó Standard automatic shutoff valve ŌĆó ZN2-style receiver interface to mate with ZZ9A1 or ZZ9A2 nozzle ŌĆó Bolt-on mounting flange ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate Min. Flow Rate 25 gpm (95 lpm) Max. Flow Rate 211 gpm (800 lpm) Operating Pressure 75 psig (520 kPa) Weight 3.94 lbs (1.79 kg)

- 7. 7323.881.7601 ŌĆó Fax: 323.981.7301 JNX-01-64 ŌĆó Standard automatic shutoff valve ŌĆó 2" JIC Adapter for fuel transfer hose ŌĆó 2" NPT male thread for mounting to tank ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate Min. Flow Rate 25 gpm (95 lpm) Max. Flow Rate 211 gpm (800 lpm) Operating Pressure 75 psig (520 kPa) Weight 3.74 lbs (1.70 kg) JNX-01-64-25 ŌĆó Standard automatic shutoff valve ŌĆó 2" JIC Adapter for fuel transfer hose ŌĆó Bolt-on mounting flange ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate Min. Flow Rate 25 gpm (95 lpm) Max. Flow Rate 211 gpm (800 lpm) Operating Pressure 75 psig (520 kPa) Weight 4.35 lbs (1.97 kg)

- 8. www.fastfueling.com non-pressurizing 8 JNX-01-61 Automatic ShutoffValves JNX-01-61-25S ŌĆó Remote automatic shutoff valve ŌĆó Code 61 inlet adapter ŌĆó 2" NPT male thread for mounting to tank ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate ŌĆó Automatic shutoff valve ŌĆó 2" NPT adapter for ZN2-type receiver ŌĆó 2" NPT male thread for mounting to tank ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate ŌĆó Remote automatic shutoff valve ŌĆó Code 61 inlet adapter ŌĆó 12-bolt mounting flange (as used on certain CAT┬« machines) ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate ŌĆó Automatic shutoff valve ŌĆó 2" NPT adapter for ZN2-type receiver ŌĆó Bolt-on mounting flange ŌĆó Works with JVX (short) or JVXL (long) jet level sensor/vent ŌĆó 211 gpm (800 lpm) maximum flow rate JNX-01B-86-25JNX-01B-86

- 9. 9323.881.7601 ŌĆó Fax: 323.981.7301 Integrated Jet Level/Sensor/Vent JVX JVXL ŌĆó Vent assembly with integrated jet level sensor, ŌĆó 3 psig relief valve, and spill protection ŌĆó Jet level sensor does not have moving parts: it is extremely reliable ŌĆó 2" NPT male thread for mounting to tank ŌĆó Short sensor length ŌĆó Vent assembly with integrated jet level sensor, ŌĆó 3 psig relief valve, and spill protection ŌĆó Jet level sensor does not have moving parts: it is extremely reliable ŌĆó 2" NPT male thread for mounting to tank ŌĆó Long sensor length 9.75" 248 mm 2.9" 74 mm 4.57" 116 mm 2.92" 74 mm Fuel Level 2.9" 74 mm 12.00" 305 mm 4.57" 116 mm Fuel Level 5.18" 131 mm Operating Pressure 75 psig (520 kPa) Weight 1.74 lbs (0.79 kg) Operating Pressure 75 psig (520 kPa) Weight 1.72 lbs (0.78 kg)

- 10. www.fastfueling.com10 ZZ9A1 Refueling Nozzles ZZ9A2 ŌĆó Industry-standard diesel refueling nozzle ŌĆó 150 gpm (570 lpm) maximum flow rate ŌĆó Automatic shutoff; works with pressurizing and non-pressurizing systems ŌĆó 1.5" NPT female inlet thread ŌĆó Durable, dependable Elast-O-Dog latching ŌĆó Field-replaceable components 17.4" 441 mm O 2.95" 75 mm 17.4" 442 mm O 2.95" 75 mm Min. Flow Rate 25 gpm (95 lpm) Max. Flow Rate 150 gpm (570 lpm) Operating Pressure 75 psig (520 kPa) Weight 5.64 lbs (2.56 kg) ŌĆó High-flow rate diesel refueling nozzle ŌĆó 211 gpm (800 lpm) maximum flow rate ŌĆó Automatic shutoff; works with pressurizing and non-pressurizing systems ŌĆó 2" NPT female inlet thread ŌĆó Durable, dependable Elast-O-Dog latching ŌĆó Field-replaceable components Min. Flow Rate 25 gpm (95 lpm) Max. Flow Rate 211 gpm (800 lpm) Operating Pressure 75 psig (520 kPa) Weight 6.10 lbs (2.77 kg)

- 11. 323.881.7601 ŌĆó Fax: 323.981.7301 11 JNC2A VR310-11 JNX-75 CSPF-C007 Accessories ŌĆó Receiver for use with remote JNX: mates with ZZ9A1 or ZZ9A2 nozzle ŌĆó Extra-light spring to minimize risk of premature shutoff ŌĆó Comes with protective dust cap ŌĆó Weld-on flange for mounting JNX-01-02-25 or JNX-01-64-25 ŌĆó 2' NPT Extension for mounting JNX receiver inside ZNC3, ZNC3L, ZNC4 and ZNC4L ŌĆó Weld-on 2" NPT half coupling for mounting automatic shutoff valve or jet level sensor/vent Wiggins offers a variety of adapters, flanges, and hose kits that allow JNX to be customized to suit even the most challenging installations. Below are just a few examples:

- 12. fuelsystems KR91 Actuating Assembly Replacement Kit KR93 Housing Handle Replacement Kit ZN2CV-100 Rebuild Kit for ZN2CV ZN2CV-1 Installation Kit for ZN2CV Fuel Systems KR92 Latching Mechanism Replacement Kit www.fastfueling.com12 ZN2CV Fuel Receiver with Check Valve ß«Ż ZZ9A1 ŌĆō Data Table Flow Rate Pressure Operating Weight (gpm) Drop Pressure (lbs) 25 1.0 psi 125 psig max 5.75 60 4.0 psi 125 psig max 5.75 100 9.0 psi 125 psig max 5.75 125 14.0 psi 125 psig max 5.75 150 24.0 psi 125 psig max 5.75 7 .50 MAX 3.74 APPROX 2.00 NPT THREAD

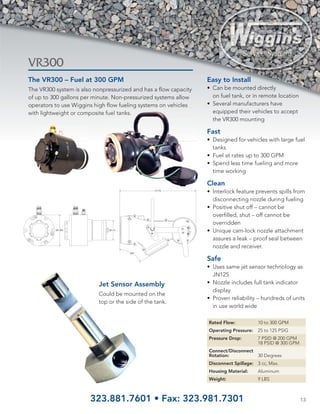

- 13. 323.881.7601 ŌĆó Fax: 323.981.7301 VR300 The VR300 ŌĆō Fuel at 300 GPM The VR300 system is also nonpressurized and has a flow capacity of up to 300 gallons per minute. Non-pressurized systems allow operators to use Wiggins high flow fueling systems on vehicles with lightweight or composite fuel tanks. Easy to Install ŌĆó Can be mounted directly on fuel tank, or in remote location ŌĆó Several manufacturers have equipped their vehicles to accept the VR300 mounting Fast ŌĆó Designed for vehicles with large fuel tanks ŌĆó Fuel at rates up to 300 GPM ŌĆó Spend less time fueling and more time working Clean ŌĆó Interlock feature prevents spills from disconnecting nozzle during fueling ŌĆó Positive shut off ŌĆō cannot be overfilled, shut ŌĆō off cannot be overridden ŌĆó Unique cam-lock nozzle attachment assures a leak ŌĆō proof seal between nozzle and receiver. Safe ŌĆó Uses same jet sensor technology as JN125 ŌĆó Nozzle includes full tank indicator display ŌĆó Proven reliability ŌĆō hundreds of units in use world wide (├ś3.187(├ś5.060) (12.75) (60╦Ü) DESOLCNEPO Rated Flow: 10 to 300 GPM Operating Pressure: 25 to 125 PSIG Pressure Drop: 7 PSID @ 200 GPM 18 PSID @ 300 GPM Connect/Disconnect Rotation: 30 Degrees Disconnect Spillage: 3 cc, Max. Housing Material: Aluminum Weight: 9 LBS 13 Jet Sensor Assembly Could be mounted on the top or the side of the tank.

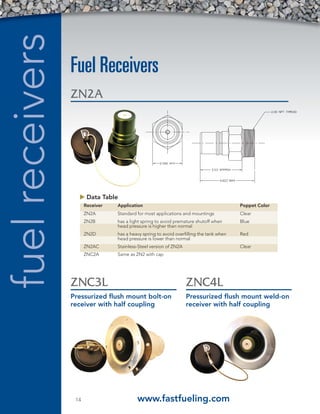

- 14. www.fastfueling.com fuelreceivers 14 ZN2A Fuel Receivers ZNC3L Pressurized flush mount bolt-on receiver with half coupling ZNC4L Pressurized flush mount weld-on receiver with half coupling ß«Ż Data Table Receiver Application Poppet Color ZN2A Standard for most applications and mountings Clear ZN2B has a light spring to avoid premature shutoff when Blue head pressure is higher than normal ZN2D has a heavy spring to avoid overfilling the tank when Red head pressure is lower than normal ZN2AC Stainless-Steel version of ZN2A Clear ZNC2A Same as ZN2 with cap

- 15. fueltankvents 323.881.7601 ŌĆó Fax: 323.981.7301 ZV10 FuelTankVents 10.1 APPROX 4.7 APPROX 2.6 APPROX 2.9 APPROX 2.00-11.5 NPT THREAD FUEL LEVEL 3.00 HEX ZV11 10.1 APPROX 3.7 APPROX 3.7 APPROX FUEL LEVEL 4-12UN-2B THREAD 2.9 APPROX 4X ├ś .375 HOLES 90┬░ APART ON ├ś 4.875 BOLT CIRCLE ZV13 FUEL LEVE L 2.0 0 NPT THREA D 3.000 HEX 5.75 APPRO X 10.00 APPRO X 3.0 0 APPROX ß«Ż Data Table Vent Mounting Length Pressure Rebuild Kit Model Style Relief Number ZV10 Pipe Thread 9.375ŌĆØ 10.2 - 12.9 psi K30285 ZV10A Welded Half-Coupling 9.375ŌĆØ 10.2 - 12.9 psi K30285 ZV10B Flange/Gasket 9.375ŌĆØ 10.2 - 12.9 psi K30285 ZV10C Same as ZV10 w/Threaded Outlet 9.500ŌĆØ 10.2 - 12.9 psi K30285 ZV10F Same as ZV10 w/Long Stem 12.50ŌĆØ 10.2 - 12.9 psi K30285 ZV11 Gas Cap Mount 9.312ŌĆØ 10.2 - 12.9 psi K30285 ZV11A Gas Cap Mount w/Long Stem 12.50ŌĆØ 10.2 - 12.9 psi K30285 ZV13 Vented Pipe Thread 12.00ŌĆØ 10.4 - 11.3 psi N/A ZV13F Long Stem 14.70ŌĆØ 10.4 - 11.3 psi N/A 15

- 16. www.fastfueling.com servicecouplings 16 ON2 / C3B12 Crankcase Receiver and Cap P1804 / P1880 Transmission Receiver and Cap OS2 Crankcase Nozzle and Plug C1807 / P1844 Transmission Nozzle and Plug Service Couplings C3B12 ON2 P1804 P1880 C1807 P1844 To order nozzle with plug (OP12), specify OSP2 Mates with ON2 and ONC2A Receivers To order receiver with cap, specify ONC2A

- 17. 6005A12 / 6008-12 Hydraulic Receiver and Cap EC285A8 / 1208-8 Coolant Receiver and Cap 6000B12 / 6009-12 Hydraulic Nozzle and Plug EC280B8 / 1209-8 Coolant Nozzle and Plug 6005A12 6008-12 6000B12 EC285A8 1208-8 EC280B8 1209-8 Mates with EC285A8 Receiver 323.881.7601 ŌĆó Fax: 323.981.7301 17 6009-12 Mates with 6005A12 Receiver

- 18. servicecouplings R11 Coolant Nozzle R12 Coolant Receiver NOZZLE Dimension Application Part # Cap A B C D T Coolant R11 R1107 2.70" Max 2.53" Approx 1.92" Approx 1.500" Hex .50" NPT Int. Thread Transmission R13 R1307 3.10O" Max 2.85" Approx 2.20" Approx 1.750" Hex .75" NPT Int. Thread Oil R15 R1507 3.300" Max 3.04" Approx 2.25" Approx 2.00" Hex .75" NPT Int. Thread Hydraulic R17 R1707 3.700" Max 3.42" Approx 2.75" Approx 2.250" Hex 1.00" NPT Int. Thread RECEIVER Dimension Application Part # Cap A B C D T1 T2 Coolant R12 R1205 2.23" Max 1.17" Approx 1.410" Max 1.250" Hex 1.187"-12UN-2A Thread .875"-14UNF-2B Int. Thread with SAE J1926/1-10 Boss Seal Surface Transmission R14 R1405 2.49" Max 1.39" Approx 1.610" Max 1.437" Hex 1.312"-12UN-2A Thread 1.062"-12UN-28 Int. Thread with SAE J1926/1-12 Boss Seal Surface Oil R16 R1605 250" Max 1.50" Approx 1.990" Max 1.750" Hex 1.625"-12UN-2A Thread 1.312"-12UN-2B Int. Thread with SAE J1926/1-16 Boss Seal Surface Hydraulic R18 R1805 2.89" Max 1.70 Approx 2.300" Max 2.000" Hex 1.875"-12UN-2A Thread 1.625"-12UN-2B Int. Thread with SAE J1926/1-20 Boss Seal Surface Service Couplings www.fastfueling.com18

- 19. 323.881.7601 ŌĆó Fax: 323.981.7301 accessories 19 ZS5 Nozzle (Mates with ZN2A) The ZS5 Bulk Transfer Nozzle is designed to mate with the ZN2 receiver. It can be used to drain a fuel tank for servicing, or to transfer fuel from one tank to another. The end fitting is the same 2-inch NPT female fitting as the ZZ9A1. Nozzle Adapters for the ZZ9A1 Bulk Fuel Coupling Breakaway Coupling ZC150 Breakaway Rebuildable Coupling Straight ZN6A Adapter Tube 90┬░ ZN6B Adapter Tube Accessories

- 20. Wiggins Service Systems has been the leader in fast fueling systems since 1967. Wiggins product is made with aerospace grade materials and combines superior performance with unmatched quality and reliability. To learn more about Wiggins fast fueling systems, contact your authorized Wiggins distributor or visit www.fastfueling.com. Wiggins Service Systems 5000 Triggs Street, Los Angeles, CA 90022 323.269.9181Fax: 323.269.3759 www.fastfueling.com www.adelwiggins.com