Wison Offshore & Marine - FLNG solution Mar 2015

- 1. Page 1www.wison.com Page : 1 Wison Offshore & Marine Ltd LNG Solution Provider March 2015 www.wison.com

- 2. Page 2www.wison.com Onshore¬†LNG (Module¬†Fabrication) Offshore¬†LNG (FLNG¬†EPCI) LNG¬†Initiatives Wison¬†can¬†provide¬†services¬†to¬†the¬†LNG¬†market¬†in¬†two¬†distinct¬†areas¬†depending¬†on¬† client¬†and¬†project¬†needs¬† Wison¬†is¬†rapidly¬†expanding¬†its¬†niche¬†in¬†the¬† offshore/floating¬†LNG¬†market¬†and¬†can¬†provide¬† complete¬†facilities¬†on¬†an¬†EPCI¬†basis,¬†specifically: ‚ÄĘ Floating¬†Liquefaction ‚ÄĘ Floating¬†Regasification¬†&¬†Storage With¬†in‚Äźhouse¬†fabrication¬†capabilities,¬†Wison¬† can¬†provide¬†construction¬†services¬†for¬†the¬† delivery¬†of¬†modules¬†for¬†large‚Äźscale¬†LNG¬†facilities: ‚ÄĘ Onshore¬†Module¬†Fabrication ‚ÄĘ Offshore¬†Module¬†Fabrication

- 3. Page 3www.wison.com FLNG Wison provides¬†its¬†clients¬†with¬†total¬†FLNG¬†solution ‚ÄĘ FLNG¬†with¬†SPM¬†offshore ‚ÄĘ FLNG¬†with¬†permenent mooring¬†near¬†shore

- 4. Page 4www.wison.com FLNG Wison¬†has¬†established¬†key¬†relationships¬†with¬†leading¬†industry¬†technology¬†providers¬†for¬† the¬†development¬†of¬†products¬†to¬†meet¬†the¬†growing¬†demand¬†for¬†offshore¬†LNG¬†facilities ‚ÄĘ Focus: ‚Äď Floating¬†Liquefaction¬†and¬†Storage¬†(FLNG) ‚Äď Floating¬†Regasification¬†and¬†Storage¬†Units¬†(FSRU) ‚ÄĘ Capabilities:¬† ‚Äď Complete¬†EPCIC¬†Delivery ‚Äď Fabrication ‚Äď Newbuild and¬†Conversion¬†hulls ‚ÄĘ Industry¬†Partners:

- 5. Page 5www.wison.com Floating¬†Liquefaction¬†Initiatives Wison¬†and¬†Black¬†&¬†Veatch¬†have¬†developed¬†a¬†‚Äúplug¬†and¬†play‚Ä̬†set¬†of¬†liquefaction¬†modules¬† for¬†rapid¬†execution¬†and¬†standardized¬†designs ‚ÄĘ Solutions¬†are¬†tailored¬†for¬†pipeline‚Äźquality,¬†dry,¬†lean¬†gas.¬†Higher¬†water¬†content,¬†heavier¬† hydrocarbon¬†content,¬†acid¬†gas¬†content¬†or¬†lower¬†inlet¬†pressure¬†can¬†be¬†accommodated¬† by¬†tailoring¬†inlet¬†section¬†(typically¬†not¬†critical¬†path) ‚ÄĘ Standardized¬†Liquefaction¬†module¬†sizes¬†of¬†0.5¬†MTPA¬†and¬†1.0¬†MTPA¬†gives¬†significant¬† flexibility¬†for¬†one¬†train.¬†More¬†trains¬†can¬†accommodate¬†¬†larger¬†LNG¬†production¬†capacity. ‚ÄĘ Standardized¬†hull¬†and¬†storage¬†designs¬†with¬†large¬†units¬†equipped¬†with¬†150,000¬†‚Äď 200,000m3 SPB¬†tanks¬†or¬†small¬†barge¬†with¬†an¬†FSU

- 6. Page 6www.wison.com Wison¬†has¬†worked¬†with¬†a¬†number¬†of¬† regasification¬†technology¬†providers¬†on¬†terminal¬† configurations ‚ÄĘ FSRU¬†conversion¬†from¬†Moss,¬†membrane¬†¬†or¬†SPB¬† tankers ‚ÄĘ Newbuild FSRU¬†with¬†SPB¬†tanks¬†(150,000¬†‚Äď 200,000m3) ‚ÄĘ Newbuild regasification¬†barge¬†(FRU)¬†with¬†storage¬† on¬†a¬†separate¬†unit¬†(FSU) ‚ÄĘ Mooring¬†system¬†designs¬†for¬†a¬†variety¬†of¬†water¬† depths¬†and¬†locations¬† ‚ÄúShallow‚ÄĚ Water ‚ÄúDeep‚ÄĚ Water MOSS FSRU Floating¬†Regasification¬†Initiatives

- 7. Page 7www.wison.com Wison¬†has¬†investigated¬†multiple¬†LNG¬†storage¬†options¬† depending¬†on¬†the¬†size¬†and¬†scope¬†of¬†projects Smaller¬†or¬†buffer¬†storage: ‚ÄĘ Exmar solution¬†utilizing¬†TGE¬†to¬†provide¬†3¬†x¬†5,367¬†m3 LNG¬† tanks¬†giving¬†a¬†total¬†of¬†16,100¬†m3 capacity ‚ÄĘ Tanks¬†are¬†robust¬†IMO¬†Type¬†C,¬†no¬†sloshing¬†and¬†no¬† secondary¬†barrier Larger¬†storage: ‚ÄĘ Concept¬†developed¬†with¬†IHI¬†¬†for¬†supply¬†of¬†proprietary¬† SPB¬†tanks¬†for¬†larger¬†storage¬†configurations ‚ÄĘ Type¬†B¬†SPB¬†tanks¬†are¬†very¬†robust¬†as¬†they¬†do¬†not¬†have¬†any¬† issues¬†with¬†sloshing ‚ÄĘ Also¬†in¬†discussions¬†for¬†the¬†utilization¬†of¬†Membrane¬†tanks¬† as¬†a¬†second¬†alternative¬†for¬†full¬†cargo¬†containment. LNG¬†Storage

- 8. Page 8www.wison.com LNG¬†Module¬†Fabrication With¬†two¬†fabrication¬†yards,¬†Wison¬†has¬†significant¬†experience¬†and¬†capabilities¬†to¬†deliver¬† modules¬†for¬†large¬†onshore¬†LNG¬†plants¬†or¬†large‚Äźscale¬†floating¬†LNG¬†facilities ‚ÄĘ The¬†Zhoushan¬†facility¬†has¬†been¬†designed¬†specifically¬†for¬†module¬†fabrication,¬†covering¬†nearly¬†1.4¬† million¬†acres¬†with¬†the¬†capability¬†to¬†build¬†and¬†load¬†out¬†up¬†to¬†30,000¬†tons¬†for¬†one¬†module¬†or¬† structure. ‚ÄĘ Wison¬†Nantong¬†is¬†one¬†of¬†the¬†only¬†fabricators¬†in¬†the¬†world¬†building¬†offshore¬†liquefaction¬† topsides ‚ÄĘ Wison¬†has¬†been¬†qualified¬†by¬†major¬†EPCI¬†contractors¬†for¬†the¬†fabrication¬†of¬†large¬†modules¬†for¬† onshore¬†plants¬†including¬†Technip and¬†Bechtel,¬†with¬†bids¬†underway¬†to¬†fabricate¬†portions¬†of¬† major¬†LNG¬†facilities Page : 8www.wison.com

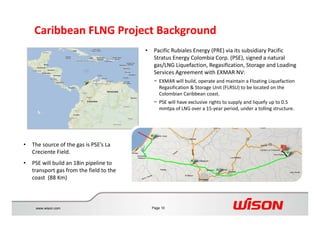

- 10. Page 10www.wison.com ‚ÄĘ Pacific¬†Rubiales Energy¬†(PRE)¬†via¬†its¬†subsidiary¬†Pacific¬† Stratus¬†Energy¬†Colombia¬†Corp.¬†(PSE),¬†signed¬†a¬†natural¬† gas/LNG¬†Liquefaction,¬†Regasification,¬†Storage¬†and¬†Loading¬† Services¬†Agreement¬†with¬†EXMAR¬†NV: ‚ąí EXMAR¬†will¬†build,¬†operate¬†and¬†maintain¬†a¬†Floating¬†Liquefaction¬† Regasification¬†&¬†Storage¬†Unit¬†(FLRSU)¬†to¬†be¬†located¬†on¬†the¬† Colombian¬†Caribbean¬†coast. ‚ąí PSE¬†will¬†have¬†exclusive¬†rights¬†to¬†supply¬†and¬†liquefy¬†up¬†to¬†0.5¬† mmtpa of¬†LNG¬†over¬†a¬†15‚Äźyear¬†period,¬†under¬†a¬†tolling¬†structure.¬† ‚ÄĘ The¬†source of¬†the gas¬†is PSE‚Äôs La¬† Creciente¬†Field. ‚ÄĘ PSE¬†will¬†build¬†an¬†18in¬†pipeline¬†to¬† transport¬†gas¬†from¬†the¬†field¬†to¬†the¬† coast¬†¬†(88¬†Km) Caribbean¬†FLNG¬†Project¬†Background

- 11. Page 11www.wison.com The¬†FLNG¬†Solution ‚ÄĘ FLNG¬†solution¬†is¬†a¬†non‚Äź propelled¬†barge¬†moored¬†to¬†an¬† offshore¬†jetty ‚ÄĘ FLNG¬†is¬†to¬†be¬†located¬†4¬†Km¬† offshore¬†in¬†14m¬†of¬†water ‚ÄĘ FLNG¬†storage¬†and¬†process¬† requirements¬†are: ‚Äź Storage¬†‚Äź 16,000¬†m3 ‚Äź Liquefaction¬†‚Äď 0.5¬†MTPA ‚Äź *Regasification¬†‚Äď 400¬†MMSCFD ‚ÄĘ Additional¬†storage¬†provided¬† through¬†170,000m3 LNG¬† Floating¬†Storage¬†Unit¬†(FSU)¬† *Regasification¬†option¬†(400MMSCFD): ‚ÄĘ 65%¬†of¬†Colombia‚Äôs¬†electricity¬†comes¬†from¬†hydropower ‚ÄĘ In¬†some¬†years¬†(la¬†Nina)¬†water¬†shortages¬†may¬†require¬†importing¬†LNG¬†to¬†generate¬†power¬†to¬† maintain¬†supply

- 12. Page 12www.wison.com ‚ÄĘ Wison¬†is¬†the¬†primary¬†EPCIC¬†contractor¬†to¬† EXMAR¬†for¬†the¬†barge‚Äźbased¬†FLSU ‚ÄĘ Wison‚Äôs¬†Scope: ‚Äź Project¬†Management ‚Äź Engineering ‚Äź Procurement ‚Äź Construction ‚Äź Commissioning ‚Äź Transportation ‚Äź Installation ‚Äź Start‚Äźup ‚ÄĘ Major¬†subcontractors¬†:¬† ‚Äź Black¬†&¬†Veatch:¬†Topside¬†LNG¬†Equipment¬†Design,¬† Procurement¬†&¬†Commissioning ‚Äź TGE:¬†Cargo¬†Tanks¬†&¬†Cargo¬†Handling¬†Systems Exmar CFLNG¬†Project ‚ÄĘ Barge¬†Particulars: ‚Äź Length: 144m ‚Äź Breadth: 32m ‚Äź Depth: 20m ‚Äź Draft:¬† 5.4m ‚ÄĘ Hand¬†over: 2015

- 14. Page 14www.wison.com ‚ÄĘ Black¬†&¬†Veatch‚Äôs¬†patented¬†PRICO¬ģ¬†Single¬† Mixed¬†Refrigerant¬†technology¬†¬†is¬†the¬†simplest¬† form¬†of¬†mixed¬†refrigerant¬†cycle ‚ÄĘ B&V¬†has¬†considerable¬†experience¬†in¬†the¬†field: ‚Äź 22¬†global¬†LNG¬†plants¬†in¬†operation ‚Äź 14¬†plants¬†under¬†construction ‚ÄĘ Process¬†is¬†scalable¬†over¬†wide¬†capacity¬†range,¬† but¬†core¬†process¬†remains¬†the¬†same ‚ÄĘ Compact¬†layout¬†with¬†modular¬†philosophy¬† lends¬†itself¬†to¬†use¬†offshore ‚ÄĘ Simplicity¬†of¬†process¬†results¬†in¬†relatively¬†low¬† cost ‚ÄĘ Simplified¬†operations¬†lead¬†to¬†quick¬†startup PRICO¬ģ¬†SMR¬†Liquefaction¬†Technology

- 15. Page 15www.wison.com ‚ÄĘ TGE¬†to¬†provide¬†3¬†x¬†5,367¬†m3 LNG¬†tanks¬†providing¬†a¬† total¬†of¬†16,100¬†m3 capacity¬† ‚ÄĘ Tanks¬†are¬†robust¬†IMO¬†Type¬†C,¬†no¬†sloshing¬†and¬†no¬† secondary¬†barrier,¬†strong¬†against¬†inner¬†and¬†outer¬† pressure¬†with¬†safe¬†and¬†simple¬†control ‚ÄĘ Tanks¬†are¬†designed¬†for¬†easy¬†operation¬†and¬† maintenance ‚ÄĘ TGE¬†has¬†more¬†than¬†25¬†years¬†experience¬†in¬†the¬†field¬†and¬† more¬†than¬†100¬†gas¬†carrier¬†contracts ‚ÄĘ Stand‚Äźalone¬†tank¬†design¬†selected¬†to¬†minimize¬†overall¬† project¬†schedule¬†‚Äď tanks¬†may¬†be¬†fabricated¬†in¬†parallel¬† and¬†lifted¬†into¬†FLRSU¬†hull¬†at¬†shipyard ‚ÄĘ TGE¬†also¬†to¬†supply¬†cargo¬†transfer¬†system,¬†and¬†¬† associated¬†gas¬†safety¬†systems,¬†electrical¬†equipment¬† and¬†instrumentation,¬†¬†and¬†auxiliary¬†systems Gas¬†Handling¬†and¬†Transfer¬†System

- 17. Page 17www.wison.com Bracket¬†&¬† Fender¬† Elements ‚ÄĘ FLNG¬†is¬†moored¬†to¬†four¬†guide¬†piles¬†using¬†a¬† bracket¬†system¬†that¬†allow¬†vertical¬†motion¬† (heave)¬†of¬†barge¬†hull¬†only ‚ÄĘ FSU¬†is¬†(conventionally)¬†moored¬†to¬†mooring¬†piles¬† on¬†offshore¬†jetty FLNG¬†Mooring¬†Arrangement

- 18. Page 18www.wison.com ‚ÄĘ Pipeline¬†gas¬†will¬†enter¬†FLNG¬†via¬†(conventional)¬† export¬†hoses¬†between¬†FLNG¬†and¬†jetty ‚ÄĘ LNG¬†will¬†be¬†offloaded¬†from¬†FLNG¬†to¬†FSU¬†via¬† midship manifolds¬†using¬†EXMAR‚Äôs¬†STS¬†(ship‚Äźto‚Äź ship)¬†transfer¬†system. ‚ÄĘ System¬†is¬†well‚Äźproven¬†with¬†more¬†than¬†500¬† transfers¬†recorded Product¬†Flow¬†‚Äď LNG¬†Export LNG¬†Loading/Offloading

- 19. Page 19www.wison.com ‚ÄĘ Use¬†of¬†proven¬†international¬†Project¬†Management¬†team¬†and¬† procedures ‚ÄĘ Experienced¬†technology¬†partners¬†and¬†willingness¬†to¬†share¬†risks ‚ÄĘ Defined¬†Client¬†and¬†Sub‚ÄźContractor¬†interface¬†management¬† protocol¬†considering¬†the¬†international¬†nature¬†of¬†the¬†project¬† and¬†multiple¬†sites ‚ÄĘ Develop¬†early¬†Level¬†4¬†schedule¬†and¬†the¬†governing¬†critical¬†path,¬† regularly¬†update Execution¬†Strategy ‚ÄĘ Focus¬†on¬†quality¬†and¬†problem‚Äźsolving¬†to¬†produce¬†‚Äúon‚Äźtime‚Ä̬†and¬†‚Äúfirst¬†time¬†right‚Ä̬† engineering ‚ÄĘ Experienced¬†commissioning¬†management¬†to¬†ensure¬†system¬†readiness,¬†performance¬† potential¬†and¬†zero¬†failure¬†on‚Äźsite¬†in¬†Colombia

- 20. Page 20www.wison.com ‚ÄĘ Fully¬†operational¬†in¬†2006 ‚Äí Located¬†at¬†the¬†bank¬†of¬†the¬†Yangtze¬†River¬† (76¬†km¬†from¬†the¬†open¬†sea) ‚Äí Occupies¬†640,000¬†square¬†meters¬†and¬†maintains¬† 735¬†meters¬†of¬†river¬†front ‚Äí 290¬†meter¬†x¬†68¬†meter¬†drydock ‚ÄĘ Throughput¬†capacity: ‚Äí Annual:¬†¬†77,000¬†Tonnes ‚ÄĘ Staffing:¬† ‚Äí Peak:¬†¬†3,500¬†(including¬†contractors) Nantong¬†Yard www.wison-offshore.com Page : 20www.wison.com

- 22. Page 22www.wison.com ‚ÄĘ Following¬†yard¬†commissioning,¬†FLNG¬†will¬†be¬†loaded¬†onto¬†transport¬†vessel¬†for¬†dry¬†transport¬†to¬† Colombia ‚ÄĘ FLNG¬†will¬†be¬†offloaded¬†at¬†inshore¬†location¬†and¬†wet‚Äźtowed¬†to¬†final¬†installation¬†site ‚ÄĘ Permanent¬†mooring¬†brackets¬†will¬†be¬†installed¬†while¬†temporarily¬†moored¬†at¬†site ‚ÄĘ Gas¬†export¬†hoses¬†will¬†be¬†installed¬†from¬†jetty¬†to¬†FLNG Voyage:¬†~13,000¬†n.miles¬†¬† Transportation &¬†Installation

- 23. Page 23www.wison.com Thank you Wison Offshore & Marine Ltd. Wison Heavy Industry Wison Offshore & Marine (USA), Inc. Hisham Yusof Business Development Director Asia Pacific Sales Wison Offshore & Marine Ltd 699 Zhongke Road, Zhangjiang Pudong, Shanghai 201210, P.R. China Email: hisham@wison.com Tel: +6013 ‚Äď 289 5686 Fax: +603 ‚Äď 2724 7125