Work part transport method

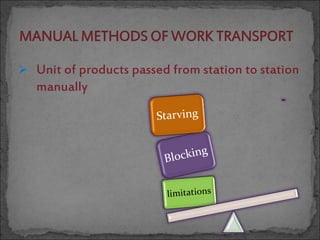

- 3.  Unit of products passed from station to station manually

- 4. Situation where operator has completed the assigned task on current work unit, but the next unit has not arrived at station.. The worker is thus starved for work

- 5. Situation where operator has completed the assigned task on current work unit but cannot pass the unit to downstream station coz operator over there is not ready to receive it.. The operator is thus blocked from working

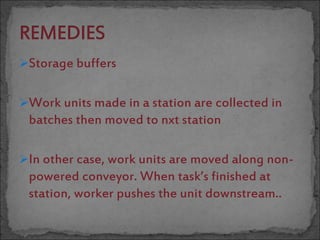

- 6. Storage buffers Work units made in a station are collected in batches then moved to nxt station In other case, work units are moved along non- powered conveyor. When task’s finished at station, worker pushes the unit downstream..

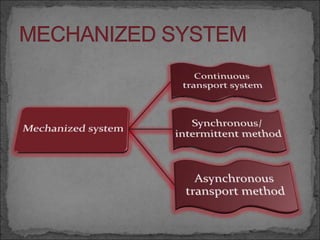

- 8. Simple n convenient. Suitable for light weight materials involving manual operation. Here conveyor moving at slow speed is used. Conveyor system is either from start to end, or if flow line is long, conveyor system can be segmented. Depending on need the work part is either fixed or removable on conveyor.

- 9. Used where work part be unloaded from conveyor system, held for some time before put back on conveyor. Method is a discontinuous type. Suitable for automatic flow lines. Manual operation not suitable coz work part be loaded back on conveyor within fixed time.

- 10. Here work part is loaded at work station, while conveyor system waits till operation is completed at each work cell. Conveyor moves to nxt cell only after completion of work at processing cell. This method is more flexible

- 12. Its essential that work part be held on conveyor in proper location n orientation while being transported. These are achieved by use of pallet fixture. Designed to suit work part geometry, holding position, orientation, safe transport n transfer to workstation. Have become a part of automation system, n are essential component of automated flow line.