WT.PPTX

- 1. Authorized Channel Partner ABB Programmable Logic Control AC500 Presentation ABB Programmable Logic Control AC500 Presentation

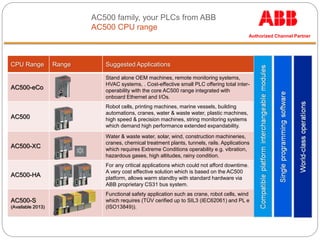

- 2. Authorized Channel Partner AC500 family, your PLCs from ABB AC500 CPU range CPU Range Range Suggested Applications AC500-eCo Stand alone OEM machines, remote monitoring systems, HVAC systems, . Cost-effective small PLC offering total inter- operability with the core AC500 range integrated with onboard Ethernet and I/Os. AC500 Robot cells, printing machines, marine vessels, building automations, cranes, water & waste water, plastic machines, high speed & precision machines, string monitoring systems which demand high performance extended expandability. AC500-XC Water & waste water, solar, wind, construction machineries, cranes, chemical treatment plants, tunnels, rails. Applications which requires Extreme Conditions operability e.g. vibration, hazardous gases, high altitudes, rainy condition. AC500-HA For any critical applications which could not afford downtime. A very cost effective solution which is based on the AC500 platform, allows warm standby with standard hardware via ABB proprietary CS31 bus system. AC500-S (Available 2013) Functional safety application such as crane, robot cells, wind which requires (TÃV cerified up to SIL3 (IEC62061) and PL e (ISO13849)).

- 3. Authorized Channel Partner AC500 family, your PLCs from ABB AC500 CPU rangeAC500-eCoAC500 128kB 512kB 1MB 2MB > 4 MB PM591-ETH, PM592-ETH PM554 PM564 PM554-ETH PM564-ETH PM572, PM573-ETH PM582, PM583-ETH Ethernetenabled Stand-alone Fieldbusenabled Performance PM590-ETH Versatility

- 4. Authorized Channel Partner AC500 your PLC from ABB Product benefit High performance PLC for demanding applications ï Full featured high performance PLC ï Program processing time and program memory provides the performance your application needs ï Configurable I/O for easy integration of various motion control applications ï Possibility to configure analog inputs as digital inputs supports customized solutions ï High functionality with integrated onboard digital

- 5. Authorized Channel Partner AC500 your PLC from ABB Product benefit ÂĐ ABB 30 March 2015 | šÝšÝßĢ 5 Comprehensive communication options save time and money ï Integrated Ethernet interface can provides multiple communication possibilities ï Up to ten serial ports for remote IO, communication and programming ï Easy network configuration based on the widely-used CoDeSys programming software

- 6. Authorized Channel Partner AC500 your PLC from ABB Product benefit ÂĐ ABB 30 March 2015 | šÝšÝßĢ 6 Protecting your investment ï Programming software based on international standard IEC 61131-3 ï Complete range of S500 I/O can be connected ï Supports decentralized I/O ï Flexible to meet different customers requirements Easy to learn and higher compatibility saves you engineering time and effort ï Single programming tool for entire AC500 family, based on CoDeSys ï Existing AC500 libraries are compatible Profibus

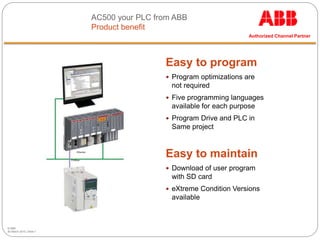

- 7. Authorized Channel Partner AC500 your PLC from ABB Product benefit ÂĐ ABB 30 March 2015 | šÝšÝßĢ 7 Easy to program ï Program optimizations are not required ï Five programming languages available for each purpose ï Program Drive and PLC in Same project Easy to maintain ï Download of user program with SD card ï eXtreme Condition Versions available Profibus Ethernet

- 8. Authorized Channel Partner AC500, your PLC from ABB Product Features ÂĐ ABB 30 March 2015 | šÝšÝßĢ 8 In summary ï A CPU integrating onboard Ethernet and Web server ï Back plane not required ï Up to 10 separate I/O modules connected to any CPUs ï 320 Local & 32,000 Remote IO and more ï Dual Processor, (High Availability) solution ï Programming tool based on CoDeSys

- 9. Authorized Channel Partner AC500, your PLC from ABB Operating, display and connection elements of AC500 ÂĐ ABB 30 March 2015 | šÝšÝßĢ 9 Terminal base: ï§ Easy snap-on of CPU and optional communication module ï§ CPU performance upgrade is convenient and fast ï§ Pre-wiring of CPU Connections Communication module: ï§ Up to 4 modules in numerous combinations to communicate with nearly Everything FieldBusPlug connector: ï§ Slaves for Profibus DP, CANopen, DeviceNet Onboard Ethernet (optional) ï§ Programming via PC ï§ Internet protocols (web server, FTP, e-mail, time sync and more) ï§ IEC 60870-5-104 COM1 (spring terminal, RS232/RS485) ï§ Programming via PC CS31 bus (master) ï§ ASCII protocol ï§ Modbus-RTU (master or slave) COM2 (Sub-D9, RS232/RS485) ï§ Programming via PC ï§ ASCII protocol ï§ Modbus-RTU (master or slave) 3 2 1 4 5 6 1 2 4 5 6 3

- 10. Authorized Channel Partner AC500, your PLC from ABB Product Line ÂĐ ABB 30 March 2015 | šÝšÝßĢ 10

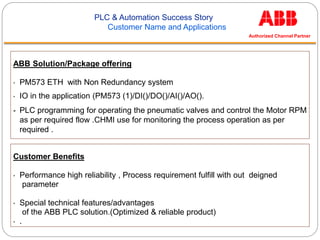

- 11. Authorized Channel Partner PLC & Automation Success Story Customer Name and Applications ABB Solution/Package offering âĒ PM573 ETH with Non Redundancy system âĒ IO in the application (PM573 (1)/DI()/DO()/AI()/AO(). ï§ PLC programming for operating the pneumatic valves and control the Motor RPM as per required flow .CHMI use for monitoring the process operation as per required . Customer Benefits âĒ Performance high reliability , Process requirement fulfill with out deigned parameter âĒ Special technical features/advantages of the ABB PLC solution.(Optimized & reliable product) âĒ .

- 12. Authorized Channel Partner System Configuration

- 13. Authorized Channel Partner Main SLD (SCADA) GOVIND MISHRA

- 14. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 15. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 16. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 17. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 18. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 19. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 20. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.

- 21. Authorized Channel Partner Objectives :- In this .PPT we will show that ïž How to configure the I/O module as per System Configuration . ïž How to configure the IP address . ïž How to configure the Third party profibus Devise (Like Encoder , MFM ) ïž How to replace the I/O module. ïž How to change the Node address in CI542 DP module . ïž How to configure the Tag in CHMI 5.1 ïž How to Configure the Trend & Alarm.