Yeast-Bread (1).ppt

- 2. ’āÆ As the name implies, yeast bread is leavened by biological leavener called yeast. Yeast is living micro-organism that thrives in warm environment and feeds on sugar. This helps to form structure in the product through the trapped air pockets and it can only be achieved by developing gluten. Baker should develop 6th sense for proper feel of well bread dough and the right ratio of liquids to dry ingredients.

- 3. 1. Lean Dough Bread Are bread made by using the basic ingredients such as flour, water, yeast, salt and shortening. Examples: Pandesal, French bread, etc. 2.Rich Dough Bread Contains added ingredients such as more sugar, butter, nuts, fruits, eggs and condiments. (Specialty Breads) a. Non sweet breads and rolls ŌĆō rich dinner rolls, brioche b. Sweet rolls ŌĆō breads with sweet filling or topping 3. Rolled-in Yeast Dough These dough incorporate fat in many layers through rolling and folding technique. a. Non-sweet rolled-in dough ŌĆō croissant b. Sweet rolled-in dough ŌĆō Danish pastry

- 4. 1. Straight Dough Method - In its simplest form, the straight dough method consists of only one step: Combine all ingredients in the mixing bowl and mix. Many bakers make good quality products by using this procedure. However, there is the possibility that the yeast may not be evenly distributed in the dough. It is therefore safer to mix the yeast separately with a little of water. a. Soften the yeast in a little of water. b. Combine the remaining ingredients, including the rest of the water, in the mixing bowl. c. Add the dissolved yeast, taking care not to let it come in contact with the salt. d. Mix to a smooth, developed dough.

- 5. 2. Modified Straight Dough Method - For rich sweet dough, the straight dough method is modified to ensure even distribution of fat and sugar. a. Soften the yeast in part of the liquid, using a separate container. b. Combine the fat, sugar, salt and flavorings and mix until well combined, but do not whip until light. c. Add the eggs gradually, as fast as they are absorbed. d. Add the liquid and mix. e. Add the flour and yeast. Mix to a smooth dough.

- 6. 3.Sponge Method - Which allows yeast to speedily and fully ferment and activate with part of the flour and water in the recipe and later incorporated with the remaining ingredients. Some baker's feel this method offers a better texture, rise and taste for very rich or heavy yeast dough recipes compared to the Straight Dough Method. Sponge dough is prepared in two stages. This procedure gives the yeast action a head start. a. Combine the liquid, the yeast, and part of the flour (and sometimes part of the sugar). Mix into a thick batter or soft dough. b. Let ferment until double in bulk. c. Punch down and add the rest of the flour and the remaining ingredients. Mix to a uniform, smooth dough.

- 7. 4. Kneading - Making bread involves considerable kneading and handling of dough. The dough is kneaded before it is allowed or ferments and again before it is molded into desired shapes. ’āÆ The purpose of kneading is to remove some of the excessive carbon dioxide in order to prevent overstretching of the gluten strands and to distribute the yeast cells throughout the dough. ’āÆ Care must be taken not to tear the dough because this will injure the gluten and reduce the elasticity of the dough. The dough is kneaded enough when it has a smooth satiny surface and smell bubbles appear under surface.

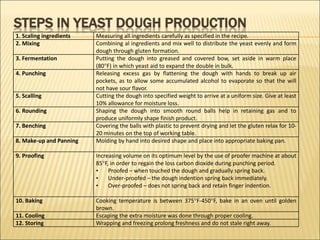

- 8. 1. Scaling ingredients Measuring all ingredients carefully as specified in the recipe. 2. Mixing Combining al ingredients and mix well to distribute the yeast evenly and form dough through gluten formation. 3. Fermentation Putting the dough into greased and covered bow, set aside in warm place (80’é░F) in which yeast aid to expand the double in bulk. 4. Punching Releasing excess gas by flattening the dough with hands to break up air pockets, as to allow some accumulated alcohol to evaporate so that the will not have sour flavor. 5. Scalling Cutting the dough into specified weight to arrive at a uniform size. Give at least 10% allowance for moisture loss. 6. Rounding Shaping the dough into smooth round balls help in retaining gas and to produce uniformly shape finish product. 7. Benching Covering the balls with plastic to prevent drying and let the gluten relax for 10- 20 minutes on the top of working table. 8. Make-up and Panning Molding by hand into desired shape and place into appropriate baking pan. 9. Proofing Increasing volume on its optimum level by the use of proofer machine at about 85’é░F, in order to regain the loss carbon dioxide during punching period. ŌĆó Proofed ŌĆō when touched the dough and gradually spring back. ŌĆó Under-proofed ŌĆō the dough indention spring back immediately. ŌĆó Over-proofed ŌĆō does not spring back and retain finger indention. 10. Baking Cooking temperature is between 375’é░F-450’é░F, bake in an oven until golden brown. 11. Cooling Escaping the extra moisture was done through proper cooling. 12. Storing Wrapping and freezing prolong freshness and do not stale right away.

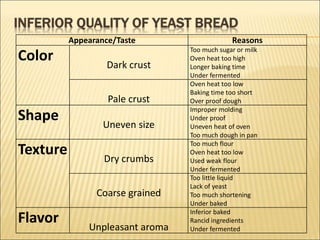

- 9. Appearance/Taste Reasons Color Dark crust Too much sugar or milk Oven heat too high Longer baking time Under fermented Pale crust Oven heat too low Baking time too short Over proof dough Shape Uneven size Improper molding Under proof Uneven heat of oven Too much dough in pan Texture Dry crumbs Too much flour Oven heat too low Used weak flour Under fermented Coarse grained Too little liquid Lack of yeast Too much shortening Under baked Flavor Unpleasant aroma Inferior baked Rancid ingredients Under fermented

- 10. THANK YOU FOR LISTENING!