Zupt Inertial Metrology - SUT / THS Subsea Metrology Seminar

- 1. Metrology

- 2. Contents Metrology surveys ŌĆō we need to be: Very efficient While delivering the required accuracy With known quality. Topics today: Dimensional Control and offsets Mechanical interfaces between instruments and structures ROV operational issues Bathymetry surveys Quality control displays while collecting data Offshore deliverables

- 3. Proven technology Zupt has been in business since 2005, operating offshore since 2007 ŌĆō first commercial client for metrology early 2008. To date we have commercially delivered >80 inertial metrologies in: Regions: West Africa rigs and survey vessels U.S. Gulf of Mexico rigs and survey vessels North Sea from rig Bahamas (42ŌĆØ dia. spool) shallow water barge with divers Fields worked: Angola: Shenzi, Pazflor, Girassol, CLOV, Dahlia, Girri Congo: Moho Bilondo GoM: Mississippi Canyon, Green Canyon North Sea: Pelican Clients: Total, BHP Billiton, Shell, LLOG, C&C Technologies, TAQA, Acergy, Statoil, Jan de Nul. Near term future work in Malaysia & Russia?

- 4. Inertial Metrology Mature and fully proven ŌĆō if you have a place to stab inertial will work Accurate: +/- 25mm to 20m jumper/spool length +/- 50mm to 50m jumper/spool length +/- 75mm to 90m +/- 100mm for longer lengths <150m Practical ŌĆō clients can QC our data within hours of first exposure Very efficient (much less boat/rig time needed) ~ 6 hours for full metrology including route survey Works in the presence of drilling noise and vibration No ŌĆ£line of sight neededŌĆØ Smaller footprint - less people on board (POB) ŌĆō less bunk space needed Vessel independent ŌĆō MSV, divers or a rig ŌĆō no need for USBL Connector independent ŌĆō Horizontal, Vertical, SHO, PLET, FLET etc. One channel needed from ROV ŌĆō hence very fast ROV mob time Inertial needs no vessel time to deploy array frames or complex subsea stands

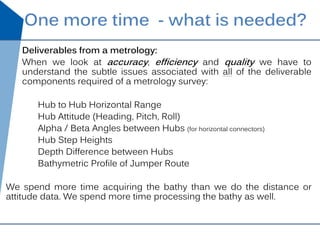

- 5. One more time - what is needed? Deliverables from a metrology: When we look at accuracy, efficiency and quality we have to understand the subtle issues associated with all of the deliverable components required of a metrology survey: Hub to Hub Horizontal Range Hub Attitude (Heading, Pitch, Roll) Alpha / Beta Angles between Hubs (for horizontal connectors) Hub Step Heights Depth Difference between Hubs Bathymetric Profile of Jumper Route We spend more time acquiring the bathy than we do the distance or attitude data. We spend more time processing the bathy as well.

- 6. DC - Offsets and accuracy Sounds obvious ŌĆō BUT! Install receptacles or survey points close to hub Make sure it is accessible Make sure both linear and angular lever arms are measured. Is it better to have a fixed receptacle further away, or tooling that is installed onto the hub face? Both!

- 7. Tooling We believe that the mechanical interface to the structure is one of the most critical issues that impacts the accuracy, efficiency and quality of metrology surveys. OR

- 8. Tooling Does it matter that the stab has an interference fit with the receptacle ŌĆō or if we can stab the tool in faster. Slightly longer stabs make up easier Protect the nose of the stab and it will always fit OR OR

- 9. Tooling Complete a make up test of tooling if at all possible Good Bad

- 10. Tooling Do not make the tooling overly heavy ŌĆō if it is going to be used in a ŌĆ£plastic receptacleŌĆØ ŌĆō it will break the receptacle!

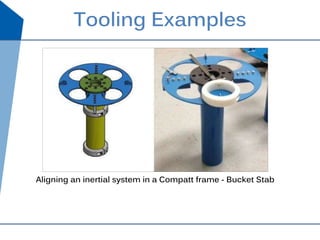

- 11. Tooling Examples Aligning an inertial system in a Compatt frame - Bucket Stab

- 12. Tooling Examples CLOV Tool Trouser Plate ŌĆ£Wine glassŌĆØ and ŌĆ£SRIPŌĆØ plate

- 13. Tooling Examples Vertical connector ŌĆō pressure cap No heading required Brownfield measurements on existing installations

- 14. ROV operational issues Power: 24V dc, 75W (battery back up internal to our tool) Communications: A single RS232 115,200 (can live with 38,400) baud rate com port. We supply a serial mux [MicroTTU] into C-PINS for all external sensors. ROVŌĆÖs rarely have the channels available that were available when talking about the job on the beach.

- 15. ROV operational issues Cabling ŌĆō ground faults and make up time!! OR

- 16. ROV operational issues Lifting and handling - T, Fishtail ŌĆō manipulator compliant

- 17. Bathy Survey - step or fly? Step Bathymetric Survey (Digiquartz) Log position every 2 m along jumper route with Digiquartz. Fly Using mini SVS and an Altimeter in addition to the Digiquartz we fly the route

- 18. Fly the route or Step the route? Why donŌĆÖt we always fly the route survey?

- 19. Step Height Survey Step Height Survey Top of hub to plant North mudline depth measurements Step Height Survey provides hub heights and mudline data.

- 20. Step height measurements Step heights at manifolds are easy. At the well ŌĆō a whole other story. Frame grabs should be included in reports to explain why.

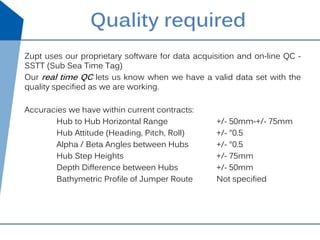

- 21. Zupt uses our proprietary software for data acquisition and on-line QC - SSTT (Sub Sea Time Tag) Our real time QC lets us know when we have a valid data set with the quality specified as we are working. Accuracies we have within current contracts: Hub to Hub Horizontal Range +/- 50mm-+/- 75mm Hub Attitude (Heading, Pitch, Roll) +/- ┬░0.5 Alpha / Beta Angles between Hubs +/- ┬░0.5 Hub Step Heights +/- 75mm Depth Difference between Hubs +/- 50mm Bathymetric Profile of Jumper Route Not specified Quality required

- 22. Real-time quality control It is critical that we see real time quality data as we are working. Position loop selection on the left. Individual data sets and their impact on the final solution are on the screen in front of us ŌĆō as we collect the data. We know when we are done! SD at ~65% of client spec.

- 23. Alpha and Beta angle quality

- 24. Deliverables ODEL (Offshore Deliverable) Prior to departure from the survey platform (vessel or rig) the metrology results are delivered to the client in the form of an offshore deliverable. ODEL contains all metrology data required for jumper fabrication. All of our data is sent emailed to Houston for QC during and immediately upon completion of survey(24/7/365). Client is issued raw data within an hour of survey completion. Results delivered within min 12 hours, max 24 hours of data acquisition.

- 31. Metrology from imaging? The next generation ŌĆō ŌĆ£Fly by metrologyŌĆØ Precise measurements made within photogrammetry like data collected by frame grabbing video imagery ŌĆō fly the route a few times ŌĆō process solution.

- 32. High resolution, geospatially correct

- 33. See separate image Image based metrology

- 34. Thank You Zupt, LLC 10963 Cutten Rd, A102 Houston, TX 77066 +1 832 295 7280 Keith Vickery kv@zupt.com Cell +1 (832) 465 4020 President www.zupt.com

![ROV operational issues

Power: 24V dc, 75W (battery back up internal to our tool)

Communications: A single RS232 115,200 (can live with 38,400)

baud rate com port.

We supply a serial mux [MicroTTU] into C-PINS for all external

sensors. ROVŌĆÖs rarely have the channels available that were available

when talking about the job on the beach.](https://image.slidesharecdn.com/sutthssubseametrologyseminar-zupt-140625154915-phpapp02/85/Zupt-Inertial-Metrology-SUT-THS-Subsea-Metrology-Seminar-14-320.jpg)