Essentials of Production

- 1. The Essentials - Production HASH MANAGEMENT SERVICES LLP CHENNAI PH: 91766 13965

- 2. Overview ï âThe Essentialsâ series from Business Sense is an initiative to empower the students(freshers) and professionals in performing more efficiently and effectively in the organization ï This document is a part of the âCertified Manufacturing Professionalâ course offered by Business Sense ï This course is aimed at bridging the gap between the institutions and the industry by providing the fundamentals of manufacturing management which are not offered by any of our institutions/curriculum ï This course would immensely benefit students and professionals who are joining manufacturing organizations ï For more details, please visit www.businessense.in ï At Business Sense, we help clients through consulting engagements focusing on improving their Operations through Lean Manufacturing Implementation covering 5S, SMED, Kaizen and other tools. ï We also serve clients on Preparation of Detailed Project Reports, Market Assessments, and Supply Chain Re-engineering. ï You can subscribe to our bi-weekly newsletter here. ï Follow us: Copyright of Hash Management Services LLP www.businessense.in

- 3. Contents ï Section 1 â Introduction and Basic Processes ï Section 2 â Shop Floor Management ï Section 3 â MIS Reports and Analyses Points Copyright of Hash Management Services LLP www.businessense.in

- 4. Introduction to Production Function ï Production is one of the most critical function in any manufacturing organization. This function represents the set of activities through which the product is made and delivered according to the clientâs requirements. ï Production function normally encompasses various departments/shops based on the type of products and the operations involved (e.g. press shop, machining, polishing, plating, assembly etc). Copyright of Hash Management Services LLP www.businessense.in

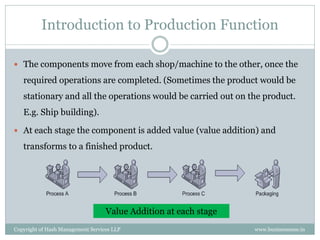

- 5. Introduction to Production Function ï The components move from each shop/machine to the other, once the required operations are completed. (Sometimes the product would be stationary and all the operations would be carried out on the product. E.g. Ship building). ï At each stage the component is added value (value addition) and transforms to a finished product. Value Addition at each stage Copyright of Hash Management Services LLP www.businessense.in

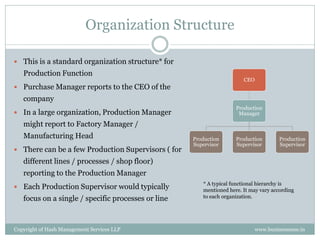

- 6. Organization Structure ï This is a standard organization structure* for Production Function CEO ï Purchase Manager reports to the CEO of the company Production ï In a large organization, Production Manager Manager might report to Factory Manager / Manufacturing Head Production Production Production Supervisor Supervisor Supervisor ï There can be a few Production Supervisors ( for different lines / processes / shop floor) reporting to the Production Manager * A typical functional hierarchy is ï Each Production Supervisor would typically mentioned here. It may vary according focus on a single / specific processes or line to each organization. Copyright of Hash Management Services LLP www.businessense.in

- 7. Responsibilities of an Engineer in Production Department âĒ Productivity - Ensuring a smooth production flow / dynamically monitoring the P production process through allocation of resources (Men/Machine/Materials) and make necessary changes based on the requirements. âĒ Quality - Meeting the Quality requirements set by the customer and taking steps to Q exceed them. Measuring and analyzing the current quality levels and taking necessary steps to improve and achieve the required quality levels C âĒ Cost â Minimizing cost (reducing reuse/defects, process modifications/improvements) âĒ Delivery - Overall responsibility of delivering finished goods as per the customerâs D requirements â Ensuring 100% on-time delivery S âĒ Safety & Morale â Achieve 0% Accidents and Incidents(Near-miss). Improving Morale of the personnel M Copyright of Hash Management Services LLP www.businessense.in

- 8. Process Flow - 1 ï Production Plan created by the Production Planning department / production manager is sent to the production supervisors ï Production supervisors plan for the dayâs production based on the weekly / monthly production plan Copyright of Hash Management Services LLP www.businessense.in

- 9. Production Process - 2 ï Order-wise requirements of all materials (calculated from the Bill of Materials (BOM)) would be obtained from the stores using Materials Issue Requisition (MIR) slip ï Once the materials are obtained they are sent to the respective process/machines for completion. The Supervisor also creates a job card for each lot/item which travels along with the product throughout the entire processes. Copyright of Hash Management Services LLP www.businessense.in

- 10. Production Process - 3 ï Quality is measured at each stage so as to reduce reworks and rejections ï At the end of the production process, necessary quality checks are made and the products are packed and delivered to the customers. Please note this is only the basic process. There may be delays / stoppages in production due to quality issues, non-availability of materials, absenteeism etc. Copyright of Hash Management Services LLP www.businessense.in

- 11. Contents ï Section 1 â Introduction and Basic Processes ï Section 2 â Shop Floor Management ï Section 3 â MIS Reports and Analyses Points Copyright of Hash Management Services LLP www.businessense.in

- 12. Daily Production Plan ï Monthly Production plan is broken down into Weekly and Daily production plan for each shop/operation by the Production manager and sent to the respective Production Supervisors ï Production Supervisor should plan for one dayâs production in advance. i.e. tomorrowâs production plan should be planned today by the individual supervisors (before office closing hours) Copyright of Hash Management Services LLP www.businessense.in

- 13. Daily Production Plan ï Once the Production supervisors obtain the daily production plan, they should plan & allocate the resources ( men, machine and materials) for the next dayâs production ï Resources and work allocation should be carried out in the previous day evening ïŽ Once the employees enter the shop floor, they should be able to pick up the materials and start working. ( If the production plan happens in the morning, the company loses around 20 minutes before employees are allocated some job and start working) Copyright of Hash Management Services LLP www.businessense.in

- 14. Shop Floor Management ï Supervisor allocates the job to the right personnel and follows it so that the production target for the day is achieved. ï In case of any changes in the plan, he/she consults with the Production manager immediately and make necessary changes in the shop floor ïŽ He/she informs the employees and arranges materials accordingly ï At the end of the day, Production status is reported to the Production Manager and the plan for the next day is done Copyright of Hash Management Services LLP www.businessense.in

- 15. Shop Floor Management Lean Manufacturing A set of Management practices originated in Japan, useful in eliminating non-value added activities and improving the productivity in a faster and efficient manner ! Copyright of Hash Management Services LLP www.businessense.in

- 16. Lean Manufacturing ï A systematic approach to identifying and eliminating waste (non- value-added activities) through continuous improvement by flowing the product or service at the pull of the customer. Doing more and more with less and lessâĶ Copyright of Hash Management Services LLP www.businessense.in

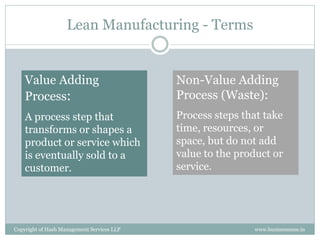

- 17. Lean Manufacturing - Terms Value Adding Non-Value Adding Process: Process (Waste): A process step that Process steps that take transforms or shapes a time, resources, or product or service which space, but do not add is eventually sold to a value to the product or customer. service. Copyright of Hash Management Services LLP www.businessense.in

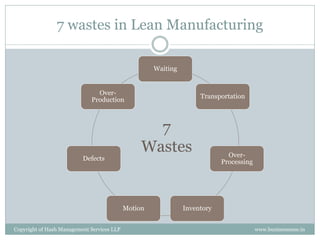

- 18. 7 wastes in Lean Manufacturing Waiting Over- Transportation Production 7 Wastes Over- Defects Processing Motion Inventory Copyright of Hash Management Services LLP www.businessense.in

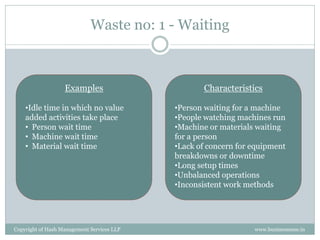

- 19. Waste no: 1 - Waiting Examples Characteristics âĒIdle time in which no value âĒPerson waiting for a machine added activities take place âĒPeople watching machines run âĒ Person wait time âĒMachine or materials waiting âĒ Machine wait time for a person âĒ Material wait time âĒLack of concern for equipment breakdowns or downtime âĒLong setup times âĒUnbalanced operations âĒInconsistent work methods Copyright of Hash Management Services LLP www.businessense.in

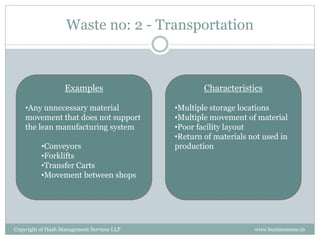

- 20. Waste no: 2 - Transportation Examples Characteristics âĒAny unnecessary material âĒMultiple storage locations movement that does not support âĒMultiple movement of material the lean manufacturing system âĒPoor facility layout âĒReturn of materials not used in âĒConveyors production âĒForklifts âĒTransfer Carts âĒMovement between shops Copyright of Hash Management Services LLP www.businessense.in

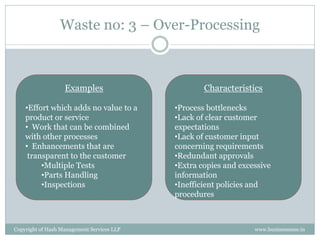

- 21. Waste no: 3 â Over-Processing Examples Characteristics âĒEffort which adds no value to a âĒProcess bottlenecks product or service âĒLack of clear customer âĒ Work that can be combined expectations with other processes âĒLack of customer input âĒ Enhancements that are concerning requirements transparent to the customer âĒRedundant approvals âĒMultiple Tests âĒExtra copies and excessive âĒParts Handling information âĒInspections âĒInefficient policies and procedures Copyright of Hash Management Services LLP www.businessense.in

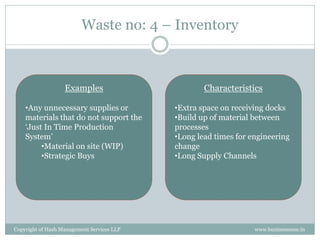

- 22. Waste no: 4 â Inventory Examples Characteristics âĒAny unnecessary supplies or âĒExtra space on receiving docks materials that do not support the âĒBuild up of material between âJust In Time Production processes Systemâ âĒLong lead times for engineering âĒMaterial on site (WIP) change âĒStrategic Buys âĒLong Supply Channels Copyright of Hash Management Services LLP www.businessense.in

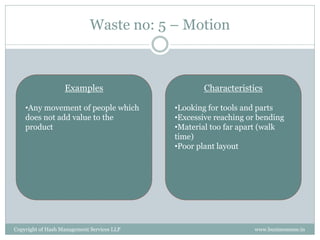

- 23. Waste no: 5 â Motion Examples Characteristics âĒAny movement of people which âĒLooking for tools and parts does not add value to the âĒExcessive reaching or bending product âĒMaterial too far apart (walk time) âĒPoor plant layout Copyright of Hash Management Services LLP www.businessense.in

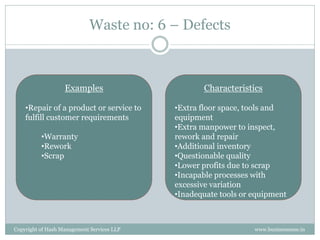

- 24. Waste no: 6 â Defects Examples Characteristics âĒRepair of a product or service to âĒExtra floor space, tools and fulfill customer requirements equipment âĒExtra manpower to inspect, âĒWarranty rework and repair âĒRework âĒAdditional inventory âĒScrap âĒQuestionable quality âĒLower profits due to scrap âĒIncapable processes with excessive variation âĒInadequate tools or equipment Copyright of Hash Management Services LLP www.businessense.in

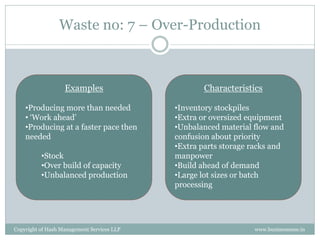

- 25. Waste no: 7 â Over-Production Examples Characteristics âĒProducing more than needed âĒInventory stockpiles âĒ âWork aheadâ âĒExtra or oversized equipment âĒProducing at a faster pace then âĒUnbalanced material flow and needed confusion about priority âĒExtra parts storage racks and âĒStock manpower âĒOver build of capacity âĒBuild ahead of demand âĒUnbalanced production âĒLarge lot sizes or batch processing Copyright of Hash Management Services LLP www.businessense.in

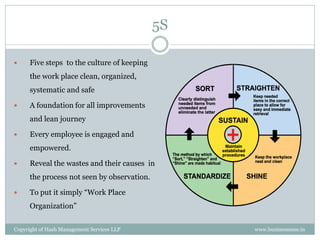

- 26. 5S 5S â a series of 5 words in Japanese language aimed at workplace organization Distinguish between what is necessary and (Seiri) â Sort unnecessary items. Remove the unnecessary items Enforce a place for everything and everything in its Seiton â Set in Order place Clean up the workplace and look for ways to keep it Seiso â Shine clean Seiketsu - Standardize Maintain and monitor adherence to the first 3âS Follow the rules to keep the workplace 5S-right Shitsuke â Sustain âHold the gain.â Copyright of Hash Management Services LLP www.businessense.in

- 27. 5S ï Five steps to the culture of keeping the work place clean, organized, systematic and safe ï A foundation for all improvements and lean journey ï Every employee is engaged and empowered. ï Reveal the wastes and their causes in the process not seen by observation. ï To put it simply âWork Place Organizationâ Copyright of Hash Management Services LLP www.businessense.in

- 28. End of Free Content ï Please visit our website www.businessense.in to access the full course â âCertified Manufacturing Professionalâ ï Our website also contains list of ready-to-use templates and report formats containing Charts and pivot tables. ï Templates and report formats are available for Purchase, Stores, Production, Quality, Maintenance and HR functions ï These templates come in excel /word and can be downloaded and used right away ï At Business Sense, we help clients through consulting engagements focusing on improving their Operations through Lean Manufacturing Implementation covering 5S, SMED, Kaizen and other tools. ï We also serve clients on Preparation of Detailed Project Reports, Market Assessments, and Supply Chain Re-engineering. ï You can subscribe to our bi-weekly newsletter here. ï Follow us: Copyright of Hash Management Services LLP www.businessense.in